NaN / 0

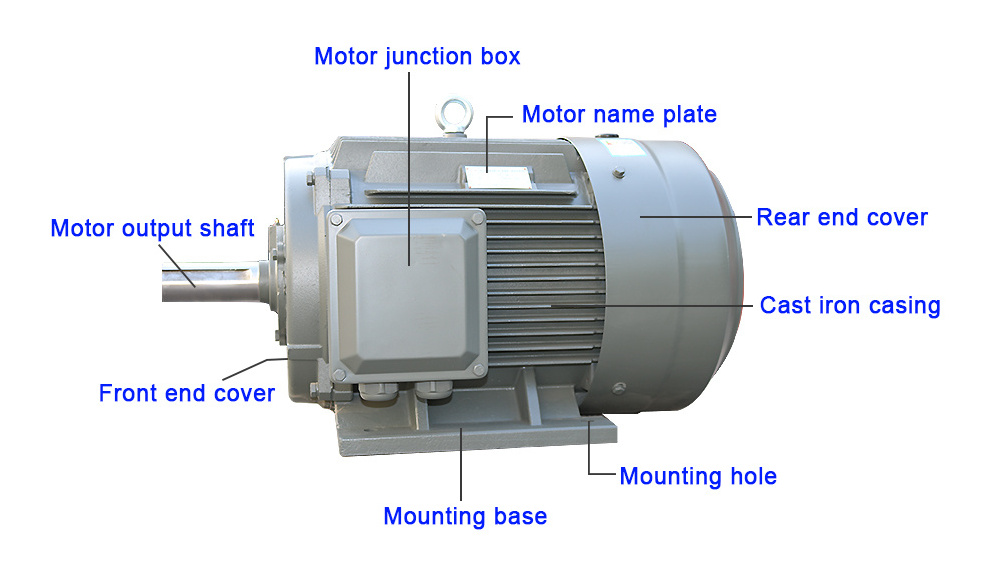

YE3 50Hz ordinary motor three-phase asynchronous motor three-phase AC motor

Get Latest Price

US$ 120

≥1 Sets

Quick Details

AC Voltage:

380v

Warranty:

1 years

Place of Origin:

Shandong, China

Brand Name:

ZRFX

Product Details

1、

Motor overview

The motor in the circuit is represented by the letter M (D in the old standard). Its main function is to generate driving torque. As the power source of electrical appliances or various machinery, the generator is represented by the letter G in the circuit. Its main function is to convert mechanical energy into electrical energy.

2.Motor applications

The motor is mainly used in large machinery, such as blower, water pump, ball mill, compressor, rolling mill, small and micro instruments and equipment or as control elements. Three phase synchronous motor is its main body. In addition, it can be used as a condenser to transmit inductive or capacitive reactive power to the power grid.

3.Based on the method of selection

1. Conditions related to type selection

1) Motor parameters: it is necessary to understand the motor's specification and model, functional characteristics, protection type, rated voltage, rated current, rated power, power frequency, etc. These contents can provide a reference for the user to choose the protector correctly.

2) Environmental conditions: mainly refers to normal temperature, high temperature, high cold, corrosion, vibration, sandstorm, altitude, electromagnetic pollution, etc.

3) Motor application: mainly refers to the characteristics of the mechanical equipment required for driving, such as fan, water pump, air compressor, lathe, oil field pumping unit and other different load mechanical characteristics.

4) Control mode: the control mode includes manual, automatic, local control, remote control, single machine operation, centralized control of production line, etc. Starting methods include direct, step-down, star angle, frequency sensitive rheostat, frequency converter, soft start, etc.

5) Other aspects: Supervision and management of production by users on site, the severity of abnormal shutdown on production, etc.

There are many factors related to the selection of protector, such as installation location, power supply, distribution system, etc.; it is also necessary to consider whether to configure protection for newly purchased motor, or to upgrade motor protection, or to improve accident motor protection; it is also necessary to consider the difficulty of motor protection mode change and the degree of impact on production; it is necessary to comprehensively consider the protection according to the actual working conditions on site Selection and adjustment of the device.

|

Check method before starting:

|

|

1. For new or long-term out of service motors, check the inter winding and winding to ground resistance before use. Generally,

500V resistance meter is used for motor below 500V; 1000V resistance meter is used for motor with 500-1000v; 2500V resistance meter is used for motor above 1000V. The resistance should not be less than 1m Ω per kilovolt, and should be measured when the motor is cooled. |

|

2. Check the appearance of the motor for cracks, whether the fastening screws are complete, and whether the motor is in good

condition. |

|

3. Check the operation of the motor drive mechanism.

|

|

4. According to the data shown on the nameplate, such as voltage, power, frequency, connection, speed, etc., whether it is consistent with the power supply and load.

|

|

5. Check the ventilation of the motor and whether the bearing lubrication is normal.

|

|

6. Pull the motor shaft to check whether the rotor can rotate freely and whether there is noise during rotation.

|

|

7. Check the motor brush assembly, whether the brush lifting mechanism is flexible, and whether the position of the brush lifting

handle is correct. |

|

8. Check the motor grounding device.

|

Hot Searches