NaN / 0

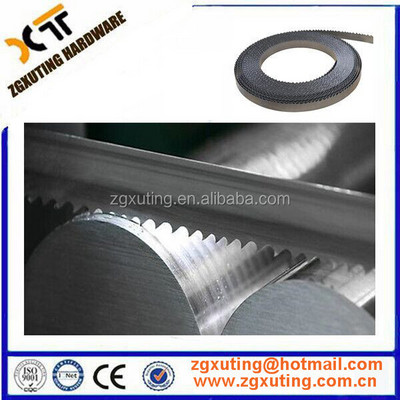

saw blade sharpening band saw blades for hard and soft metal ,wood,steel cutting

Get Latest Price

US$ 95

≥20 Pieces

Quick Details

Blade Length:

6in

Finishing:

N/A

Size:

custom made

Place of Origin:

Guangdong, China

Product Details

Bandsaw blades band saw blade for hard and soft

metal,wood,steel cutting

Product Description

Feature:

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so, therefore, we must first select the appropriate band saw blades for cutting material which, in order to achieve the best cutting effect, there is based on blade cutting material choice for large diameter steel on coarse tooth blade for cutting required, otherwise the best choice for relatively modest fine-tooth blade, there is to regular equipment maintenance and maintenance, so as to greatly improve work efficiency, but also help to save costs.

| Product name | Band knife blades/ band saw blade |

| Material | Alloy Steel |

| Cutting ability | Can cutting ordinary steel ,stainless steel,carbon steel,all kinds of hard and soft wood ,etc. |

| Performance |

Strong stability and

abrasive

resistance.

|

TIP:

The new band saw blade before you use must be run-in. Running a no or no run-good life of blade is a good run-in blade 1/3 or less. When the blade can only use half the normal run-feed pressure / rate and cutting speed, until the sawn surface area 300-1000cm2. Then gradually the feed rate and cutting speed to normal.

And here is our test result :

Use Method:

Use the following method, maybe you can get a longer saw blade life:

1 .. The new saw blade when in use, within the first two hours, only with half the usual rate cut sawing, then gradually increase the speed to normal speed cut

2 .. Sawing three hours later, set the saw blade slightly retensioning number

Be sure to relax on the saw blade Saw

3. After work, in order to avoid metal fatigue, fracture, remember next time you use certain tension.

Packaging & Shipping

| packing | usually pack in box or bag ,can be pack as customer requested |

| shipping | Send goods out in 3-5 working days after the receipt of payment, if the client do not have a shipper in China, we will choose the fast , cheap and safe shipping way for our clients. |

FAQ

1.Contact information

Contacts :Nicole Tang

Email:zgxuting@hotmail"dot"com

Skype:xuting-nicole

what'sapp:+86 13828883872

2.Place the order

Products confirmation→Price agreement→Receipt of payment→Goods preparation and shipping→Goods received→Feedback.

3.Payment terms

we can accept paypal, T/T bank transfer and western union.

4.For some products, custom-made service is available, more details please contact the contact person.

5.Usually the goods will be sent out in 3-5 working days after the receipt of payment.

company information

Shenzhen Xuting (International) Co., Ltd , established in 2002, located in Guangdong, China. Specialize in plastic molding parts, molding date stamps, plastic shutter, machinery shutter, stopcock ,thimble ,ejector sleeve ,assist device ,stamping mould parts, punches, guide sleeve, polyurethane products(pu rods, pu rollers, pu sheet, etc), die spring, punch press oil feeding machine, punch press air feeder, feeding cradle, pin gauge, round pin, etc.

Our advantage products:electric air grinder, hand-operating test pump, thread insert, industrial glue, spare parts cabinet , polishing paste, ROCOL RTD LIQUID, lifting jack , height setting device, electric gas torch, demagnetizer, bead screw, etc.