NaN / 0

liquid glass epoxy resin and hardener 2:1 best epoxy resin for carbon fiber surface coating artistic design Resin beach frame

Get Latest Price

US$ 6.8

≥20 Kilograms

US$ 6.5

≥200 Kilograms

US$ 5.8

≥2000 Kilograms

US$ 5.5

≥5000 Kilograms

Quick Details

CAS No.:

5888-33-5 7473-98-5

Other Names:

Epoxy resin and hardner AB glue

MF:

227-561-6 231-272-0

EINECS No.:

DYABJ-0005

Product Details

Products Description

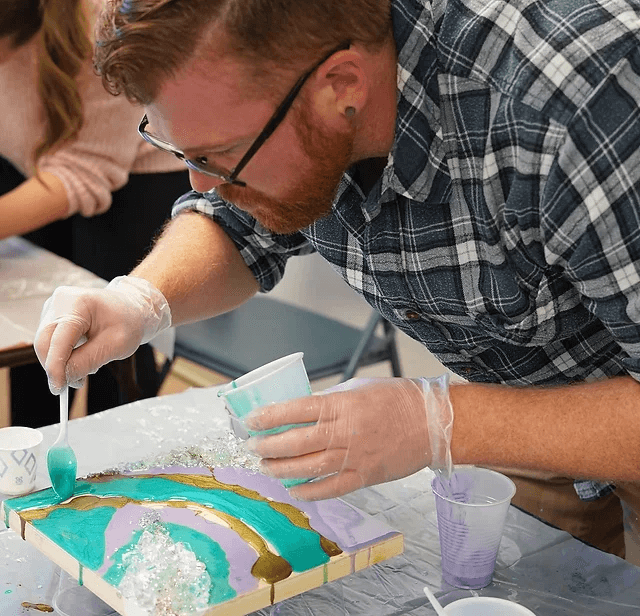

China factory wholesale Liquid crystal clear epoxy resin 2:1

less smell and very bright,Often used on

carbon fiber surface coating,

Art top coat, countertop coat,

river table making, countertops ,

trays

and cutting board and more

woodworker - artist.

We provide high quality crystal clear epoxy resin 2:1 ratio with super

high transparency, excellent defoaming performance, ultra-low odor, high hardness, yellowing resistance,

especially our TF-6201 model, which is the best epoxy resin with yellowing resistance in the 2:1 ratio, so you don't have to worry about the epoxy artwork yellowing soon;

Contact us for more information

2:1 clear epoxy resin is usually used in the manufacture of medium or large epoxy resin crafts or

Surfboard coating, such as river tables, bar tables, coffee tables, trays, cutting boards, dinner plates, Serving board, coasters, epoxy resin wall clocks,epoxy resin decorative lamps

,

and other kinds of transparent resin crafts ornaments,

how rich your imagination you create epoxy resin artwork is how rich.

If you don't know what kind of epoxy resin to buy to finish your artwork,

click here to contact us

,

we will give you professional advice and support you at any time!

The following is part of the epoxy resin handicraft product Show:

Of course, not only these,

smaller DIY jewelry, accessories, pendants 2:1 ratio epoxy resin can also be completed

; 2:1 ratio epoxy resin needs some experience in operation compared to 1:1 ratio epoxy resin,

if you want to know the operation method and precautions,

please contact us!

Regarding the 2:1 ratio clear epoxy resin, we have a variety of models and specifications, and different models and specifications are suitable for different applications.

Common specifications:

A200+B100ml,A3kg+B1.5kg,A5kg+B2.5kg,A10kg+B5kg and more ,We

support customization of different specifications. Contact for more information with suppliers!

support customization of different specifications. Contact for more information with suppliers!

|

Epoxy resin:Hardener

|

2:1

|

|

|

Reference Applications

|

River table, bar tables, coffee table, tray, cutting board, dinner plate, service tray, coaster, epoxy clock, surfboard coating,art painting coating, epoxy resin decorative lights and other transparent resin crafts.

|

|

|

Maximum single

pouring depth

|

3-5cm

,Can be poured multiple times

|

|

|

Premium UV Resistance

|

√

|

|

|

Ultra-high transparency

|

√

|

|

|

Surface dry time

(Fast curing type)

|

4-6 Hours

|

|

|

Fully cured time

(Fast curing type)

|

24-36 Hours

|

|

|

Surface dry time

(Slow curing type)

|

8-10 Hours

|

|

|

Fully cured time

(Slow curing type)

|

24-48Hours

|

|

|

Specific cured time:Depending on

Temp & volume Mixed ratio,Fillers, toners, pastes, pigments

|

|

|

|

Optimum Workability Time

|

Recommended After Fully Cured At 24 Hours

|

|

Our Services:

Our factory accept OEM&ODM;

Support custom Logo Printing;

Offer Free product catalog,images,and videos;

Support sample service;

Some products support Amazon FBA Shipping.

Our 2:1 formula is easy to measure & even easier to pour!

Directions for use:

Step 1:

The ideal working temperature is around 77°F. Best results can be obtained at temperatures between 70°F and 85°F, in a clean, dry, dust-free environment. Avoid working in high humidity. We recommend using this product on a leveled and flat work surface.

Step 2:

Measure product in accordance with your intended use. Prepare 2 parts Base Resin to 1 part Curing Agent by liquid volume. Pour the Curing Agent first and then the Base Resin into a clean, smooth-sided container large enough to hold all the liquid and allow room for mixing.

Step 3:

The material must be mixed thoroughly for at least 6-8 minutes. Be sure to scrape the container sides, bottom, and corners as you mix. Be careful not to whip excessive air into the mixture. If mixing a gallon, use a power mixer set to “hand speed.” For smaller quantities, use stir sticks. Do not mix more than a gallon. Pour into a new, clean container and mix for an additional minute.

Step 4:

Pour the mixed resin onto the surface and distribute evenly with a squeegee or gloved hand. Continue to pour remaining material to achieve the desired thickness, allowing the resin to flow evenly over the project’s sides. Resin can be poured up to 2” thick per pour, and up to 4”depending on the volume of the pour.

Step 5:

Use a heat source such as a heat gun to remove any bubbles by adding a small amount of heat to the surrounding area. The bubble will rise to the surface and pop.

Step 6:

If you are going to make a second pour, the first pour should still be slightly sticky. Once the second pour is made,bubbles may once again need to be removed. Material will feel hard after 48-72 hours, but full cure and maximum hardness can require up to 7 days, depending upon the temperature.

PRO TIP:

If you wish to apply paper decals or other objects under the TF-6201 surface, those objects need to be bonded to the surface either with TF-6201 Epoxy or craft glue. Some wood may take the material well in a single coat; however, many types of wood require a seal coat to prevent air bubbles from rising out of the wood and ruining the surface. Older, more porous pieces of wood may contain both air and moisture that can contaminate the finish. In this case, the user may first paint on a very thin coat of Super Clear Table Top Epoxy, allowing that to set before pouring the new layer.

Hot Searches