NaN / 0

semi automatic qt 4-24 Concrete hollow block making machine price bricks cement maker

Get Latest Price

US$ 4690

≥1 Sets

US$ 4550

≥3 Sets

Quick Details

Type:

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Autoclaved aerated concrete block (AAC)

Brick Raw Material:

Cinder

Production Capacity (Pieces/8 hours):

4000-60000 Pieces/day

Brick size:

400*150*200 mm, Other, 400*200*200 mm

Product Details

Product Description

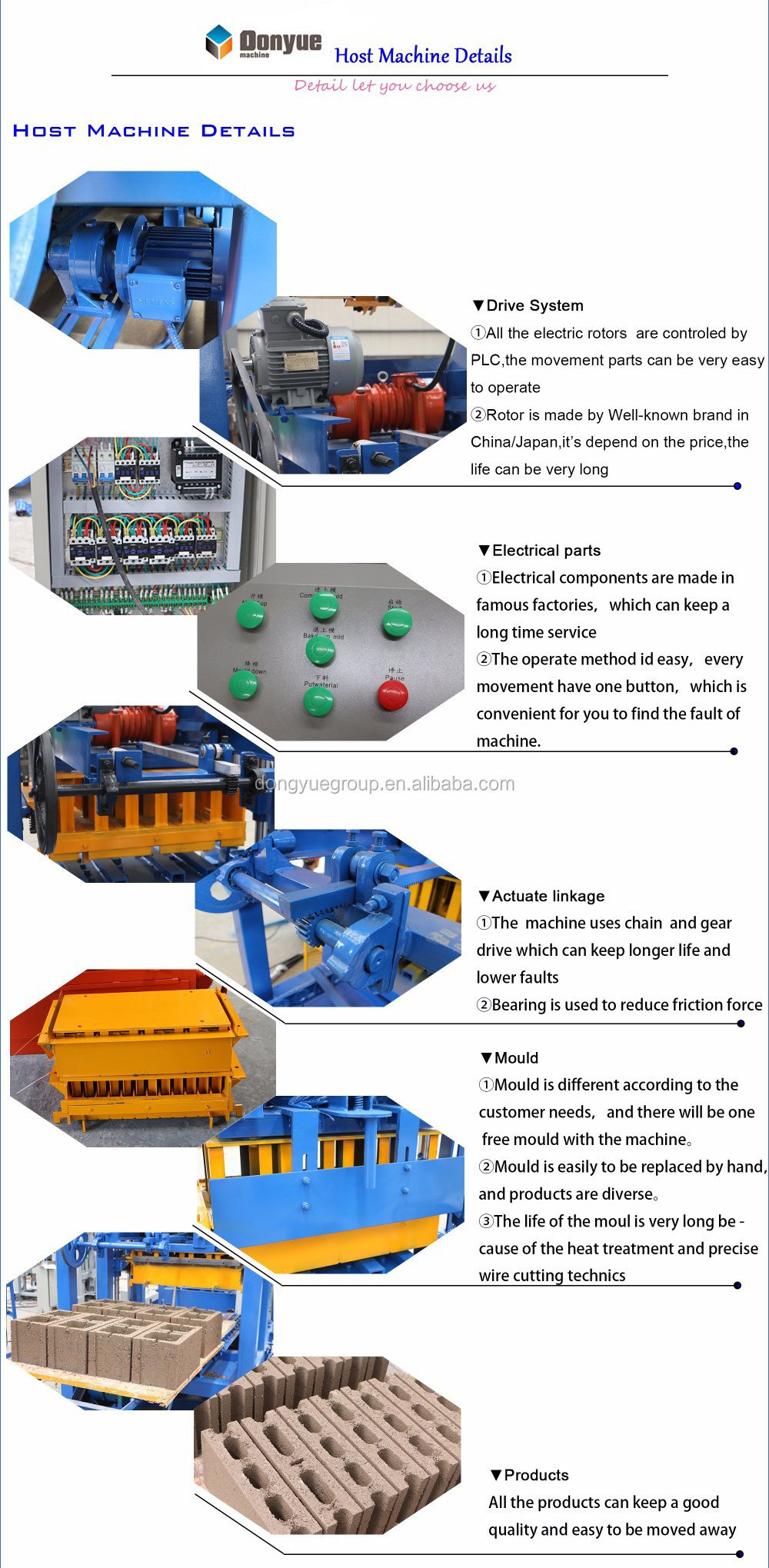

Advantages of QT4-24 Block machine

Superior vibratory effect: Simultaneous vibration.the blocks produced are of good quality, large density and high strength

High quality machine body: Best steel Q235B and special welding techniques (CO2 gas protective welding ) make the machine strong and of high resistance to vibration

The motor for the host machine is Germany SIEMENS brand or ABB brand

High Quality Mould: All moulds are processed through carburizing heat treatment, which will prolong the machine life span for at least 5 years.

Perfect after-sale service: Our machine is guaranteed for one year and our staff are

available 24 hours a day 7 days a week. you can get pre-installation support, project report support

Hollow block machine QT4-24

♦.QT4-24 manual block machine can make hollow/solid/paver/Slab block.

♦.The working voltage is upto your local situtation,220v/380v/440v/etc areall available.

♦.Only 2~3workers required to finish the block making operation.

♦.Material:Concrete which is made of Fly ash,gravel,sand,slag.Cement is necessary as the binder.

Products details

Material Proporation of QT 4-24 high quality concrete block/brick making machine

a. 8-10% cement, 30-40 % sand , 50-60% crushed stone.

b. 8-10% cement, 30% flyash, 60% sand or stone powder

Our Service

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, planThe condition of building factory, feasibility analysis for brick machine production line)(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line anytime,if you need, we can Make inVitation

card for you.

(5) Introduce the company file, product categories and production process.

Sale

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale

(

1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix,and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time,keep well communication with each other

Packing & Delivery

Our company

Our certification

Contact Me

Hot Searches