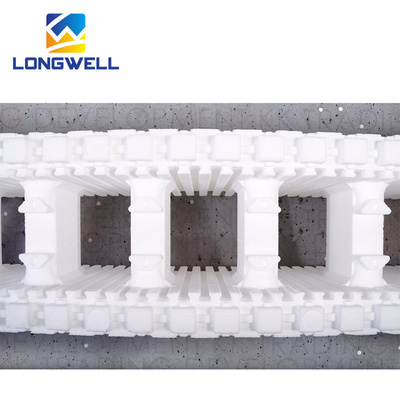

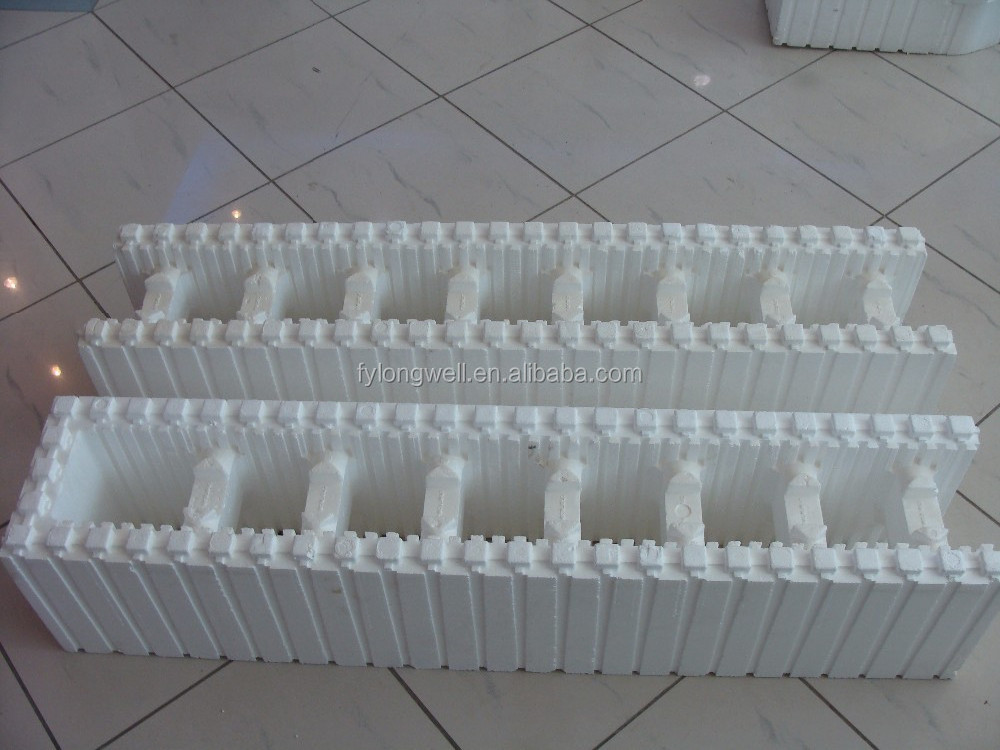

Name: Construction Blocks(wall panels)

Size

: 1200 x 250 x 250 mm, All elements made of EPS grade F(fire retardant), density 25gr/litr

Insulating Concrete Forms (ICFs) are hollow EPS forms that are erected at the construction site, and then filled with five or six inches of reinforced concrete. Unlike traditional concrete forms, which are removed after the concrete cures, ICFs are left in place.

ICFs give you all the benefits that have made concrete the material of choice for home building worldwide: Solid, lasting construction that resists the ravages of fire, wind, and time. But ICFs do plain concrete one better – or rather, two better – by giving you two built-in layers of foam insulation.

1) Energy Efficiency

The solid concrete wall construction blocks of ICF eliminates drafts associated with framed buildings, achieving energy savings for homeowners.2) Quiet

ICFs act as a sound barrier, reducing sound penetration by up to 50 percent.3) Secure

Buildings constructed with ICF are resistant to fire, violent winds and extreme elements. This technique can also be used to build above-grade safe rooms that are resistant to hurricanes and tornados.

4) Cost Effective

With ICF, contractors will reduce jobsite labor and material costs. Homeowners will benefit from lower utility costs.

Name: Construction Blocks(wall panels)

Size

: 1200 x 250 x 250 mm, All elements made of EPS grade F(fire retardant), density 25gr/litr

* Inquiry and consulting support.

* Sample testing support.

* View Factory.

* Training how to instal the ICF blocks online

Outer package: standard export wooden cases.

Inner package: plastic paper or wrapped with stretch film and etc.

Shipment:

By sea from Shanghai or Ningbo port

By train from Hangzhou station

By truck from Kashgar, Urumuqi or other checkpoint

Longwell Industry insist on cooperating with customers, offers one-stop services, including factory checking, machines selection, production arrangement, production tracking, before-delivery inspection, load-container checking, document confirmation and after-sales service. Timely report is given to clients for all details. so as to improve working efficiency, competitiveness and realize mutual benefits.

1. Full automatic and continuous production.

2. Controlled by touch screen and PLC, easy to operate.

3. High output and save energy.

4. Stable quality and less.

1. Controlled by PLC and touch screen, easy to operate.

2. With vacuum system creates fast product molding and cooling, while decreasing water content.

3. With multiple de-molding device, it can handle any difficult to de-mold product.

1. All block mold frames are treated by heat-treatment to ensure strength.

2. Taiwan original hydraulic station and all good quality parts.

1. Made of high quality aluminum material, and mould frame is made by extruded aluminum alloy profile, strong and long lasting.

2.Processed by CNC machines, mould sizes are precise.

3. All cavities and cores coated by Teflon.

Q. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance. Other payment terms can also be negotiated.

Q. How about your delivery time?

A: Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q. Can you produce according to the samples?

A: Yes, we can produce mold by your samples or technical drawings.

Q. Do you test all your machines before delivery?

A: Yes, we have 100% tested before delivery.

Q. Do you have some videos where we can see the line producing?

A: Yes, we can provide some videos for reference.

Q: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.