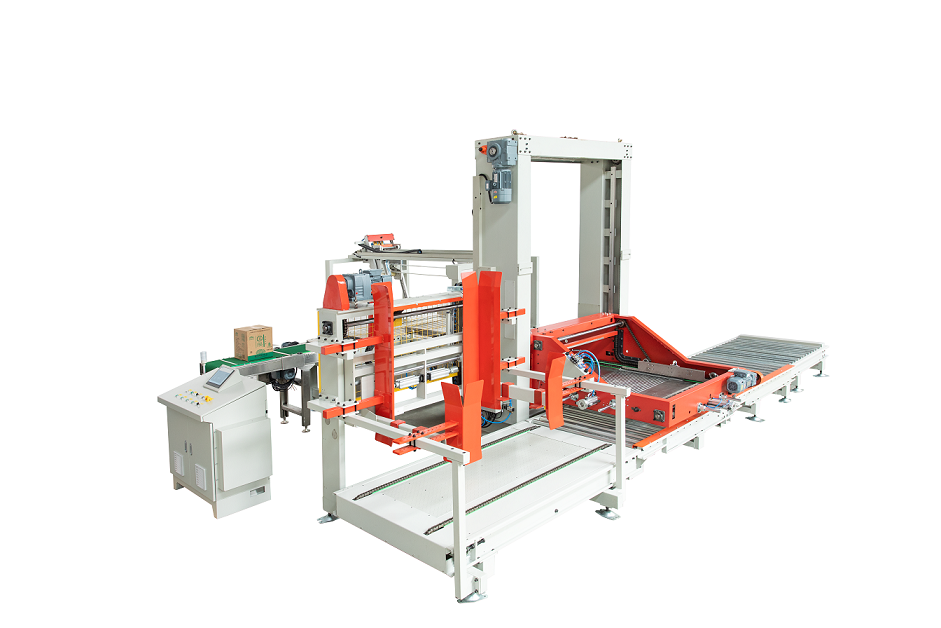

The palletizer is to put the cartons that have been loaded with container, put them on the pallet according to a certain arrangement, and automatically stack them. Palletizers can greatly reduce labor and labor intensity, and are indispensable equipment for modern production lines. Commonly used in automated production lines such as beverages, beer, medicine, food, and construction.