NaN / 0

Ultrasonic Valve Controlled Wireless Remote Reading Smart Water Meter 15mm-40mm

Get Latest Price

US$ 40

≥1 Pieces

Quick Details

Warranty:

One year

Type:

Ultrasonic meters, Prepaid water meters

Place of Origin:

Shanghai, China

Brand Name:

OEM

Product Details

Tip: There are many types of water meters, and the communication methods are different. If you have any questions, please email us or contact our online customer service directly. contact details

ultrasonic water flow meter

Ultrasonic valve controlled water meter

ultrasonic water meter (15mm-25mm)

Smart Digital Ultrasonic Water Meter 15mm-25mm

Provide OEM and ODM services

Prepaid water meter

Smart water meter

Product Description

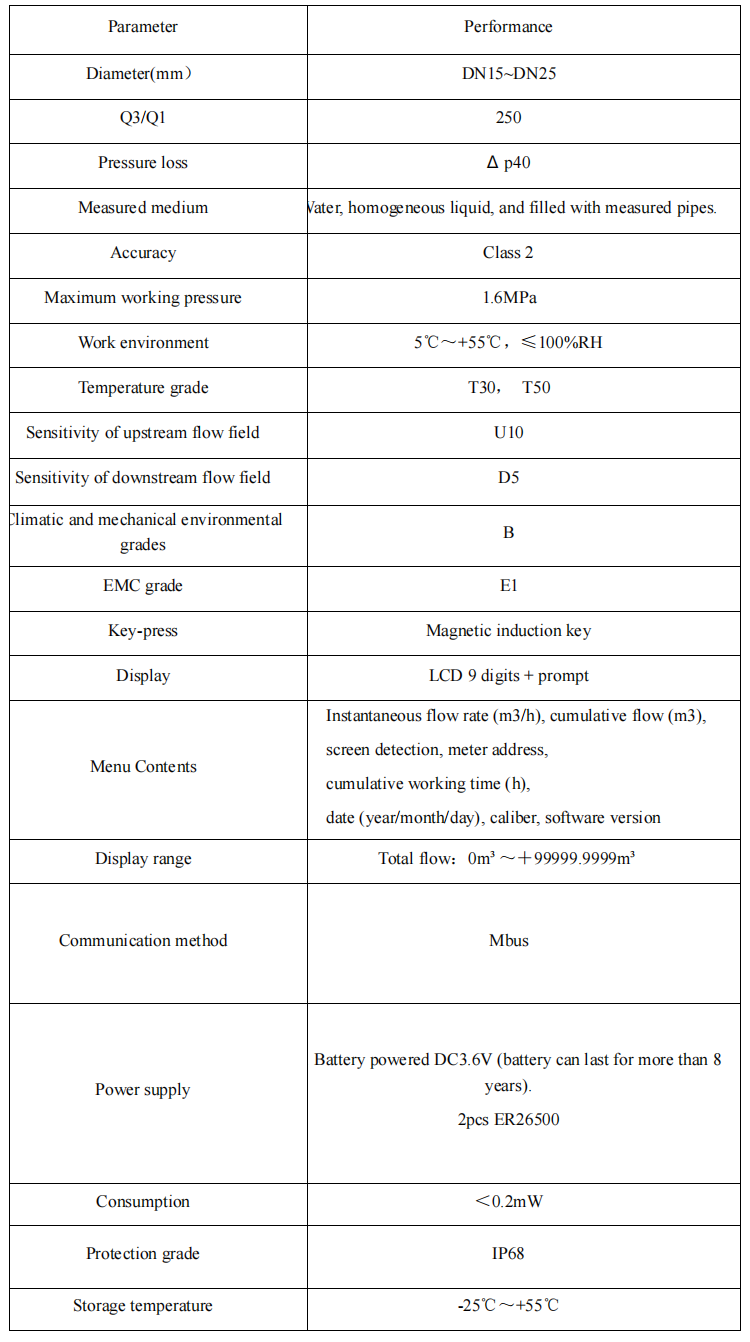

Ultrasonic Water Meter-DN15- DN25

Compared with the ordinary mechanical water meter body, the ultrasonic water meter body has no moving

parts, there is no mechanical wear when using, so the ultrasonic water meter can be used for a long time, it is

stable and reliable and has always maintained a good measurement accuracy.

Ultrasonic water meter has large range ratio and small start flow rate, and the range ratio of water meter can

be: R250; The start flow rate can be minimum 0.003m³/h.

The measuring accuracy of ultrasonic water meter is Class 2, but outgoing quality control can be required

according to standard class 1.

Ultrasonic water meter is highly adaptable to change of fluid temperature and can be temperature grades

T30/T50/T70.

Ultrasonic water meter has strong abilities of anti-static and anti-magnetic interference , the ability of

anti-static can reach more than 12000V, will not be attacked by magnetic field.

Ultrasonic water meter adopts micro power consumption design technology to minimize the overall power

consumption of the water meter. Two pieces ER26500 battery with a capacity of 8500mA *2 and super large

capacity capacitor can make the service life of the whole meter reach more than 8 years.

Ultrasonic water meters has a variety of communication methods, such as wireless NB-iot, LoRa

communication, and wired M-BUS, RS485 communication, etc., and equipped with infrared communication, the

meter parameters can be configured, and the meter data can be read through infrared communication.

ultrasonic water mete equipped with valve control and IC card prepaid function, the control of valve can be

carried out through the IC card.

carried out through the IC card

Flow parameter

Flow range of data:

The Cube meter has 3 different flow ranges to choose, R=250, R=400, and R=500. For different flow ranges, there will be having different flow rate performance

Outline dimension: The water meter could cooperate with different pipe lengths.

Multi-Communication

Wired communication :

M-BUS -RS485 -Protocol: EN1434, Modbus, CJ188.

Wireless communication :

Lora: 470MHz,868MHz,915MHz -LoraWan: 470MHz,868MHz,915MHz -GPRS/GSM: Local mobile operators' support is required/needed.

NB-IoT: Local mobile operators' support is required/needed.

LED Menu

Note: The LCD display can be customized according to customer’s requirement.

Accuracy Curve

Communication mode information:

Pulse Parameters

1. Pulse Width: t1=500us, t2 ≥ 500us

2. Pulse Equivalent: 1 L/Pulse

3. The yellow cable is Signal, the blue cable is GND ( there are sticky notes on the lines )

Product Components:

Ultrasonic pipeline: The meter’s body (pipe) structure has no mechanical moving parts and no wear/tear. Which makes it maintenance free. It is resistant to any disturbance of ripple flow, which make the measurement highly accurate. The structure of the pipe is simply built to overcome the high pressure loss and eliminates any leakage.

Transducer: Adopting High-performance piezoelectric devices, makes the metervery stable and highly accurate. The reflector material is stainless steel which prevents all sediments wear resistance, impact resistance, aging resistance, high temperature resistance, corrosion resistance... etc.

Calculator:

Receive signals from flow sensors and temperature sensors for flow calculation, storage, display systems, data transmission, etc.

Installation and connection.

1. Installation and Connection Requirements:

Installation should be strictly in accordance to the site professional engineering design, and alteration without engineers permission should be strictly prohibited.

2. Instrument Installation Position:

Installed in vertical pipeline for upward (or oblique upward) flow of liquid, followed by horizontal pipeline, try to avoid downward flow of liquid. (or oblique downward) flowing pipes to prevent liquid from running with the gravity and create air pockets.

Installation position should not be selected at the highest point of pipeline direction to prevent abnormal measurement due to bubble accumulation in pipeline.

3. Installation method

Cut off the installation instrument of the water supply pipeline and set aside the

location of the installation instrument as shown in the figure.

Concentric alignment of instrument,

Pipeline and tightening of pipeline blade and instrument thread with the appropriate wrench

Instrument installation completed.

Remote reading the meter data from

The whole system mainly consists of ultrasonic water meter with Lora (MBUS, RS485)communication, collector &repeater and management system.

The whole system mainly consists of ultrasonic water meter with Lora(MBUS, RS485) communication, collector &repeater and management system.

Provide a variety of flow meters, water meters

Packaging & Shipping

Hot Searches