NaN / 0

MINI CAP IRONING BLOCKING MACHINE CAP MAKING MACHINE AUTOMATIC CAP HAT STEAM MACHINE

Get Latest Price

US$ 1250

≥1 Sets

US$ 1150

≥5 Sets

US$ 1000

≥10 Sets

Quick Details

Voltage:

220v

Place of Origin:

China

Power:

4000

Dimension(L*W*H):

60*60*70cm

Product Details

Products Description

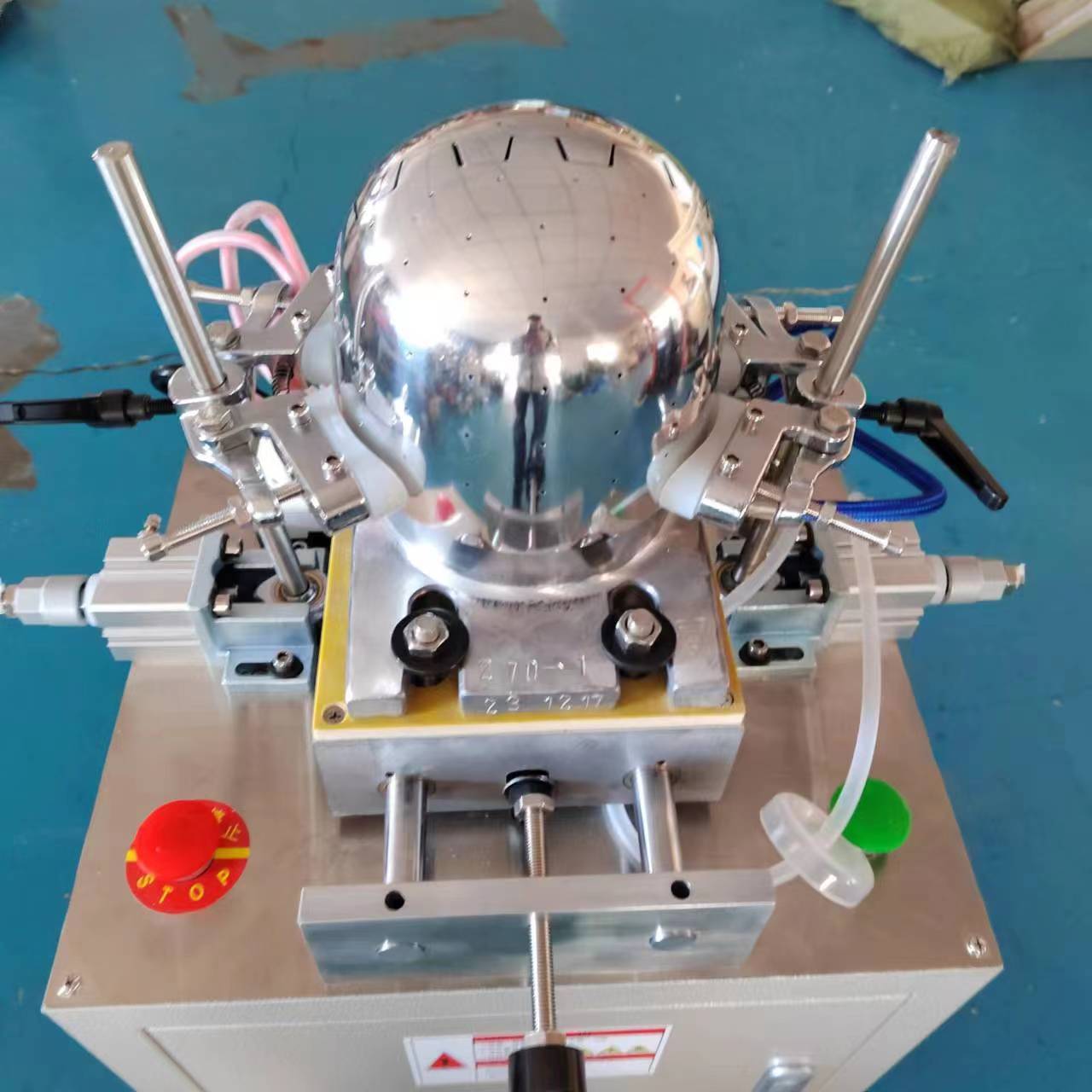

Automatic Small Type Baseball Hat Ironing Machine Industrial Hat Cap Ironing Machine Mould Single

**Cap Heat Press Machine**

A cap heat press machine, also known as a cap molding machine, is a device used to shape and mold caps. It consists of a heating element, a molding die, and a pressure mechanism.

**Working Principle:**

1. Place the cap on the molding die.

2. Activate the heating element to heat the cap.

3. Apply pressure to the cap using the pressure mechanism.

4. Maintain the heat and pressure for a specific duration.

5. Release the pressure and remove the cap from the molding die.

**Features:**

* Easy to operate and maintain.

* Fast and efficient molding process.

* Produces high-quality, precisely molded caps.

* Versatile; can be used with various cap materials.

* Cost-effective solution for cap manufacturing.

**Applications:**

* Cap manufacturing industry: To shape and mold caps made of different materials, including cotton, polyester, nylon, and leather.

* Garment industry: To attach logos, designs, or embellishments onto caps and hats.

* Promotional products industry: To create custom caps and hats for promotional events and campaigns.

* Craft and hobby enthusiasts: To personalize and decorate caps and hats for personal use or as gifts.

The cap heat press machine is a valuable tool for businesses and individuals involved in cap manufacturing, customization, and decoration. It offers a convenient and efficient way to achieve professional-quality results.

Product Paramenters

Name: Small cap ironing machine Model: DS-51 Voltage: 220V Power: 4kw Volume: 60 * 60 * 70 (cm) Weight: 72kg

Recommend Products

Packing & Delivery

⭐ For small-sized goods shipped by express, usually the packaging method is carton/ ply-wooden box;For large-sized goods shipped by land/sea/air, we will pack the goods with standard export wooden boxes.

⭐ If the goods you ordered we have in stock, we usually deliver out within 7-10 working days.If the goods need to be pre-ordered,you can contact us to determine the exact delivery time.

⭐ If the goods you ordered we have in stock, we usually deliver out within 7-10 working days.If the goods need to be pre-ordered,you can contact us to determine the exact delivery time.

Hot Searches