NaN / 0

Aluminum Steel Hook On Ceiling Panel Production Line Metal Suspended Ceiling System Tile Roll Forming Machine Factory Price

Get Latest Price

US$ 78000

≥1 Sets

US$ 75000

≥5 Sets

US$ 73000

≥10 Sets

Quick Details

Weight (KG):

15000

Core Components:

motor, other, Bearing, PLC, Engine, Pump, Gear

Place of Origin:

China

Brand Name:

KINGREAL

Product Details

Products Description

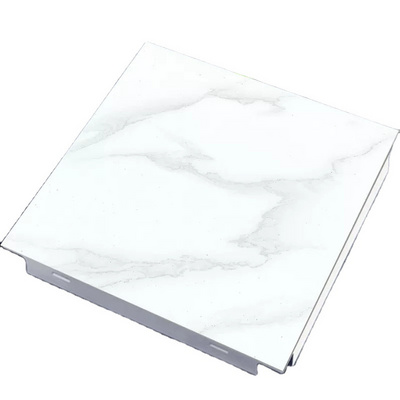

HOOK ON CEILING PANEL PRODUCITON LINE

KINGREAL Hook On Suspended Ceiling Panel production line is deigned for making hook on ceiling panel. Using the roll forming system to make the metal like aluminum and GI panel. The production line is automatic and high speed for your efficient production.

The height of the folding edge of the hooked on ceiling is generally 30mm, the two sides of the rectangle, while hooked inside to the outside, so the name "hooked board".

Applications

Working Procedure

Decoiler -- Precision Leveling -- CNC Shearing Machine -- Corner Shearing Machine -- Punching Machine -- Main Roll Forming Machine -- Cut To Length And Bending Machine

1. Hydraulic Decoiler

2. Straightener

3. Punching Station

4. Roll Forming Machine

5. Cut To Length And Bending Machine

2. Straightener

3. Punching Station

4. Roll Forming Machine

5. Cut To Length And Bending Machine

Technique Feature

Fully automatic feeding

1. The principle of average force in each pass, the average force on the whole line of rollers, wear balance, and extend the service life of rolls. Rollers using C12MoV material is the use of its wear resistance, heat treatment to use the red hardness of C12MoV, after quenching, two or even three tempering to achieve hardness.

2. Branded electronic components for automatic production. For different scale and operation theory machine, we install the suitable components for your machine. Using the branded PLC control system combine the self-develop control system to stable and automatic produce.

3. KINGREAL have rich experience in suspended ceiling production line, we not only provide the hook on ceiling production but also the carrier machine solution for the different types ceiling. You can get the whole production line foe ceiling industry.

Hot Searches