NaN / 0

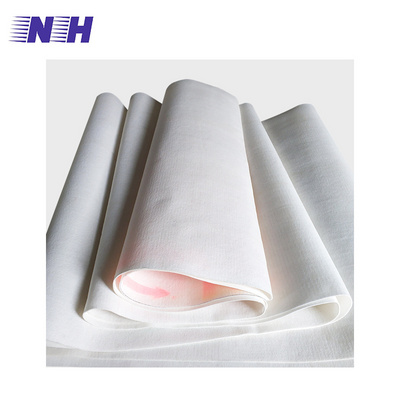

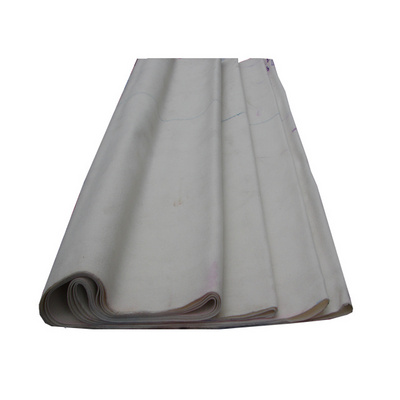

Paper Mill Dryer Felt, Felt for Paper machine

Get Latest Price

US$ 12

≥1 Kilograms

Quick Details

Material:

100% Polyester

Pattern:

Dyed

Feature:

Sustainable, Anti-Static

Use:

Industry

Product Details

Paper making machine mill press polyester felt fabric

Product Description

The Press felt is an important role in removing the water from the paper web after the forming section, at the same time imparting smoothness and conveying it to the dryer section. For this reason, The press felt needs to provide the following functions: water removal, smoothness and runability. In recent years, larger and faster paper machines require press felts of even higher consistency and quality.

| Product name | BOM felt, Single layer, double layer, triple layer of paper making felt |

| Use position | pickup felt, MG felt, Dryer felt, press felt |

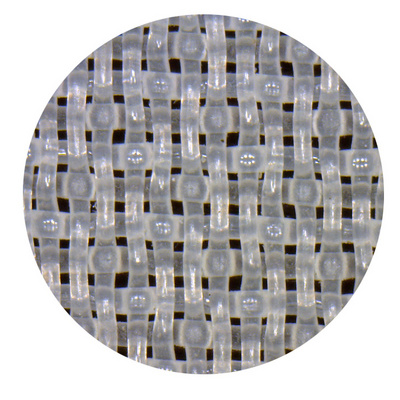

| Material | Nylon/ Synthetic Filament or multi-filament |

| Paper machine | Cylinder/Super forming/Fourdrinier/Inclined wire machine/Nip wire machine for forming section felt/ press felt |

| Machine velocity | ≤ 800m/min |

| Paper | ≥8g/m2 kinds of Paper |

| Feature: |

Less elongation Easy to clean no-mark on paper Good filtration |

| Service life | 3months- 9months |

| BOM TECHNICAL PARAMETER |

Felt GSM: 700-1200g/m2 Felt GSM Tolerance: ≤±4% Air permeability: 30-120cfm Tensile Strength: ≥2000N/5cm Elongation Percentage: ≤ 1% Width Variation: ≤±2cm |

Advantage of Our Paper making felt:

1.High anti-compaction capacity.

2. Extremely high elasticity and recoverability.

3. Strong drainability abd larger void volumn.

4. Long holding time of wear resistance and plastic strenth of felt.

5. Smooth felt surface and even pressure distribution.