NaN / 0

Used tire recycling machine for making rubber powder rubber granule machine

Get Latest Price

US$ 15000

≥1 Sets

US$ 14800

≥5 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

Huarui

Core Components:

main host

Voltage:

380V or customize

Product Details

Used tire recycling machine for making rubber powder

rubber granule machine

Production Flow

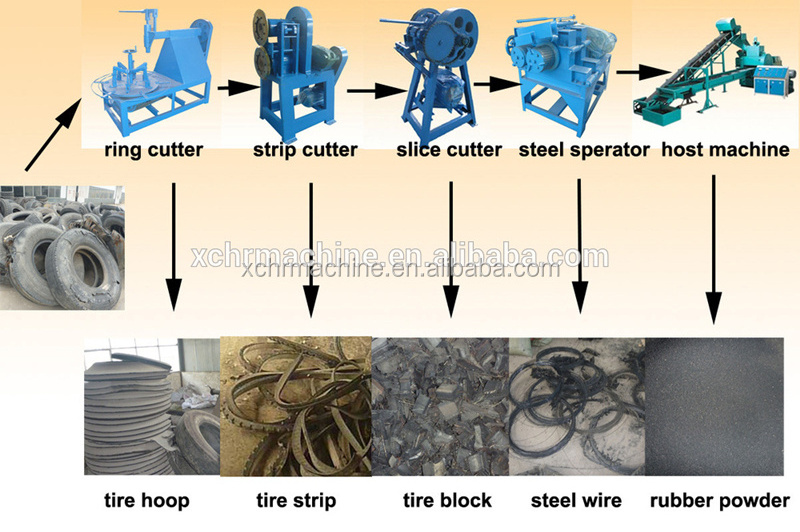

Rubber Powder making machinery process flow:

The whole set of rubber powder making machinery consists of three main parts:

1.scrap tires separating equipments

2.crusher set

3.grading magnetic separator.

Product Description

Rubber Powder making machinery

1.Scrap tire separating equipments

These machines are special for disintegration, circle cutting, strip cutting and chunk cutting of scrap wire tires. us e d tire recycling machine

(1) The circle cutting machine is an alone accessory machine, it puts the tire which is greater than 650 type (both nylon and steel wire) flat on the machine, locking tire inside opening through up and down locking system, then putting alloy tools to target to the place of disintegration of tire to cut off the mouth and nation of tire, finished in 3 minutes.

|

Name of product |

Motor power |

Weight |

Designed yield |

Specification |

|

tire circle cutting machine |

4 KW |

650 kg |

40/h |

650- 1200 mm |

(2) Strip cutting machine make use of two round special cutting tools to combination running cutting. It can cut the tire of circle into 3-8mm wide strip, to use for dicer cutting. The material of this machine’s knife disk is special alloy structural steel , diameter of knife disk isΦ390mm, hardness is 58-62GrS, more durable.

|

Motor power |

Work range |

Processing speed |

Demission |

Weight |

|

4 KW |

tire of 750-1200 mm |

20-35 strips/h |

1150mm*850mm*1200mm |

3000-5000 kg |

(3) Block cutting machine: the machine is prepared for the crush of host machine, Not only it makes the cutting strip-type waste rubber cut into about 3*8cm small pieces, but also can enter into host machine again through mutual use between sword and fixed knife, convenient to feed, high output and won’t damage roller easily.

|

Name of product |

Motor power |

Weight |

Designed yield |

Dicer specification |

|

block cutting machine |

5.5 KW |

800 kg |

0.8 T/h |

3*5*8 cm |

2.Crusher set

The crusher set consists of rubber crushing mill, conveyor and main vibrating screen.

The rubber crushing mill is a set of complete machine that mainly used for grinding and powder manufacturing. It’s equipped with alloy chilled cast iron rolls which are hard and wear-resisting.

|

Model No. |

XKP - 350 |

XKP - 400 |

XKP - 450 |

XKP - 560 |

XKP - 560L |

|

Diameter of front roll |

300 mm (groove) |

400 mm (groove) |

450 mm (groove) |

560 mm (groove) |

560 mm (groove) |

|

Diameter of back roll |

300 mm (groove) |

400 mm (groove) |

450 mm (groove) |

510 mm (groove) |

560 mm (groove) |

|

Drum working length |

500mm |

600mm |

760mm |

800mm |

1000mm |

|

Front roll liner speed |

26.2m/min |

34.5 m/min |

38.0 m/min |

40.6m/min |

44m/min |

|

Roll ratio |

1:2.5 |

1:2.5 |

1:2.5 |

1:2.5 |

1:2.5 |

|

Max roller spacing |

10mm |

10 mm |

10 mm |

10 mm |

10mm |

|

Motor power |

30KW/37KW |

45KW/55KW |

75KW / 90 KW |

90 KW/ 110 KW |

132 KW/1 60 KW |

|

Weight |

6T |

8.5 T |

11T |

17.5T |

21T |

|

L*W*H |

3.5*1.6*1.5m |

4.3*1.8*1.6m |

4.6*2.0*1.65m |

5.3 * 2.0*1.7m |

5.6*2.0*1.7m |

|

Tips: Both rollers are grooved which can improve the output. Roller material is Alloy 5Cr6MnMo. There are 8 pieces bearing inside the machine , all rolling bearing . |

|||||

3. Grading sifter and magnetic separator

The main function of these machines is to separate steel wire and tire rubber thoroughly. This kind of recycle grinding process features advanced technology, no waste gas and water and low operating cost. The steel wire magnetic separation effect is more than 99.9%. The actual power consumption of processing tires is about 150 KW/hour. And the hourly output is about 100-400 kilogram.

Shipping and packaging pictures

Our customers visiting our factory and cooperating with us

If any interest in our machines, welcome to contact us at any time:

Contact person: Sally Li

Cell/whatsapp/wechat: 0086 15638769216

Hot Searches