NaN / 0

Custom Multifunctional Stainless Steel Door Buckle Black White Lock L-Shaped 90-Degree Right-Angle Fixed Triangle Iron Bracket

Get Latest Price

US$ 0.2

≥500 Pieces

US$ 0.18

≥1000 Pieces

US$ 0.16

≥1500 Pieces

Quick Details

Place of Origin:

Beijing, China

Brand Name:

JYL

Model Number:

MSP-1226-03

Product name:

Stamping Part

Product Details

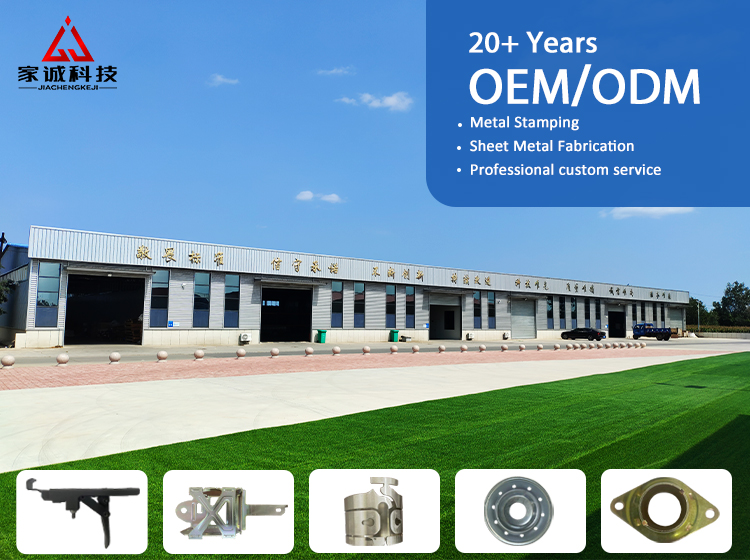

Why choose us

1. Offer free samples.

2. Welcome OEM/ODM.

3. Provide proper suggestions or solutions.

4. At least 72 hours salt spray test.

5. Offer multiple secondary operations such as reaming, drilling, heat treating, plating, painting etc.

6. Assembly well by welding, installation, paste stickers and customized package.7. Competitive price with good quality.

8. Small order is acceptable and well arranged.

9. On time deliver. (10-20 days according to order qty)

2. Welcome OEM/ODM.

3. Provide proper suggestions or solutions.

4. At least 72 hours salt spray test.

5. Offer multiple secondary operations such as reaming, drilling, heat treating, plating, painting etc.

6. Assembly well by welding, installation, paste stickers and customized package.7. Competitive price with good quality.

8. Small order is acceptable and well arranged.

9. On time deliver. (10-20 days according to order qty)

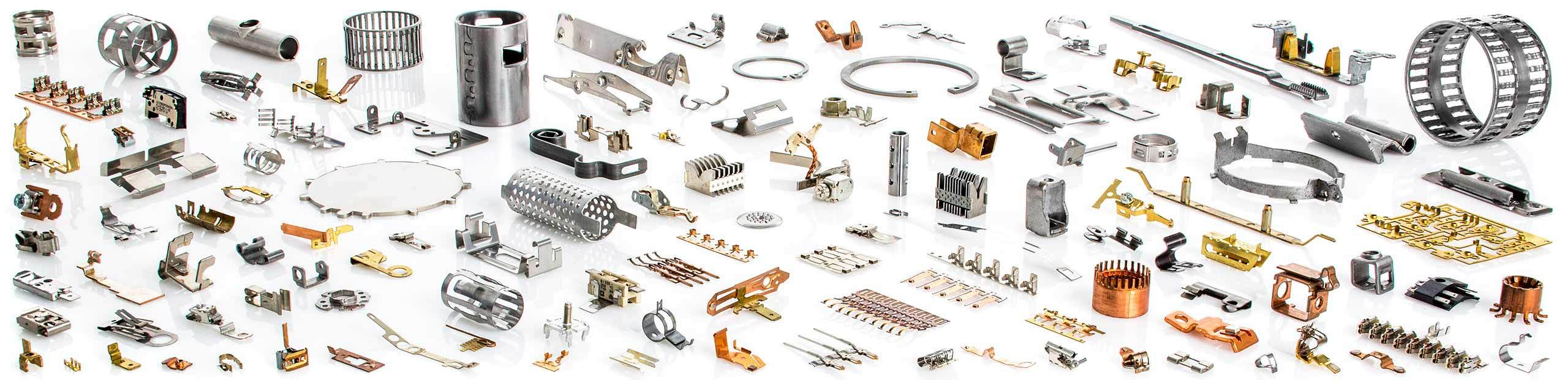

Material: steel, stainless steel, aluminum, copper, brass, alloy, etc.

Thickness: 0.1mm to 12mm, as your request

Sizes: as your request

Logo service: provided

Surface treatment: zinc, nickle, chrome plating, powder coating, painting, etc.

Delivery Time: depend on the quantities, usually around 10 days.

Application: widely used on construction, industry.

Certification: ISO

Stamping technology will be applied for this part.

Special specifications can also be produced according to drawings and samples.

Thickness: 0.1mm to 12mm, as your request

Sizes: as your request

Logo service: provided

Surface treatment: zinc, nickle, chrome plating, powder coating, painting, etc.

Delivery Time: depend on the quantities, usually around 10 days.

Application: widely used on construction, industry.

Certification: ISO

Stamping technology will be applied for this part.

Special specifications can also be produced according to drawings and samples.

|

Material

|

Metal: Stainless Steel, Brass,Copper, Brozone, Aluminum, Steel, Carbon Steel etc.

|

|

|

Plastic : PU, PVC, POM, PC, PMMA, Nylon ,Acrylic, HDPE etc.

|

|

Precision processing |

CNC machining ,CNC turning, CNC milling, drilling, grinding, wire-EDM cutting ,

Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion |

|

Surface finish/treatment

|

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving

|

|

Drawing Format

|

jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc

|

|

Tolerance

|

0.003mm-0.01mm

|

|

Quality assurance |

- Technicians self-check in production

- Engineer spot check in production - QC inspect after products finished |

|

MOQ

|

1pcs

|

|

Payment terms

|

TT/Paypal / Western Union / VISA (30% in advance, 70% balance before shipment)

|

|

Shipment

|

By express ( DHL/FEDEX/UPS/EMS/TNT.etc)

0-100kg: air freight priority, >100kg: sea freight priority, |

|

Delivery time

|

3~7 working days

|

|

Production time

|

2~10 working days

|

|

Application

|

Aerospace, Electric Vehicles, Firearms, Hydraulics and Fluid Power, Medical and Dental, Oil and Gas, and many other demanding

industries. |

Q: What do you need to provide a quote?

A: Please kindly send us the drawing or the sample of your product. Details below should be included,

A.Materials B. Surface Finish C. Tolerance D. Quantity

(Please be noted that these are essential for our quote. The specific price couldn't be quoted without any of them.)

Q: How does the payment process work?

A: Payment terms are flexible for us in accordance with specific conditions. Generally we advise 30%TT deposit, balance before

shipment.

Q: How do I know about the production?

A: We will double confirm your requirements and send you the sample for youe checking before the mass production. You will be kept

informed of any progress. And 100% quality inspection can be done before shipment.

Q: How do I know about the delivery?

A: Tracking number will be provided to you once we get it from shipping agent. Also we will keep updating the latest shipping

information for you.

Q: What will you do for after sales?

A: When our metal parts apply to your products, we will follow up and await your feedback. Any question related to our metal

parts, our experienced engineers are ready to help.

We can make dies that meet exacting dimensional tolerances. Producing thousands of metal stampings at a time.

A: Please kindly send us the drawing or the sample of your product. Details below should be included,

A.Materials B. Surface Finish C. Tolerance D. Quantity

(Please be noted that these are essential for our quote. The specific price couldn't be quoted without any of them.)

Q: How does the payment process work?

A: Payment terms are flexible for us in accordance with specific conditions. Generally we advise 30%TT deposit, balance before

shipment.

Q: How do I know about the production?

A: We will double confirm your requirements and send you the sample for youe checking before the mass production. You will be kept

informed of any progress. And 100% quality inspection can be done before shipment.

Q: How do I know about the delivery?

A: Tracking number will be provided to you once we get it from shipping agent. Also we will keep updating the latest shipping

information for you.

Q: What will you do for after sales?

A: When our metal parts apply to your products, we will follow up and await your feedback. Any question related to our metal

parts, our experienced engineers are ready to help.

We can make dies that meet exacting dimensional tolerances. Producing thousands of metal stampings at a time.