NaN / 0

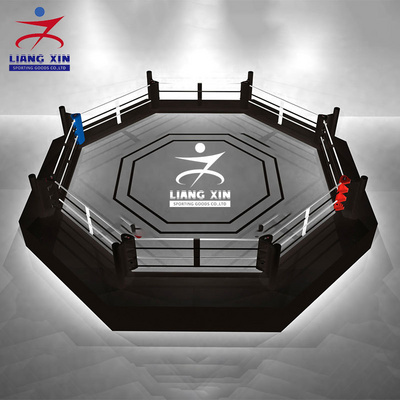

octagon fighting mma cage sale

Get Latest Price

US$ 1000

≥1 Pieces

Quick Details

Place of Origin:

Shandong, China, Shandong, China (Mainland)

Brand Name:

Liangxin

Model Number:

MMA octagon

Cage Size:

5-10m

Product Details

Shipping and package

What materials are used in a FIGHTERS Cage?

We pick the most suitable materials to build a cage. For safety, we NEVER compromise.

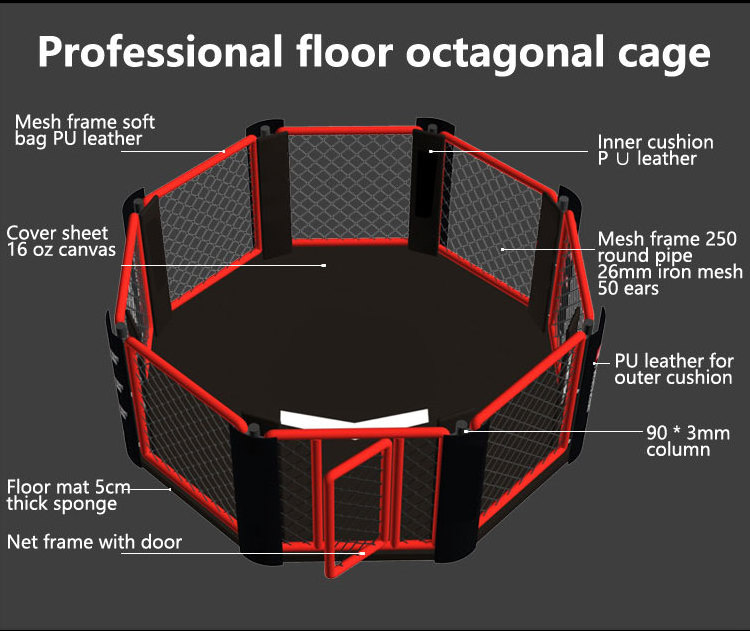

1. Cage Panel

OD of steel tube; wall thickness of steel tube; thickness of wire mesh; is it plastic dipped; color of the wire mesh; mesh hole size; is it galvanized steel wire; burst strength of the steel wire.

2. Platform Structure

Size of steel pipe; wall thickness of steel pipe; is it structural plywood; thickness of the wood board; thickness of steel plates for connection; is foot length adjustable.

3. Cage Floor

What type of foam; foam density; foam hardness; foam compression set (25% and 50%); thickness of foam; material for floor cover; how floor cover is bonded (by glue or by heat); printing method (paint spray, screen printing, UV printing)

4. Panel Rail Padding

Type of foam; tube or sheet; properties of the foam; thickness of the foam; what material for padding cover; thickness of the padding cover; properties of the padding cover.

5. Pole Padding

Is pole foam padded; If properties of the pad and cover material.

6. Pole Pad

Size of the pole pad; material inside the pole

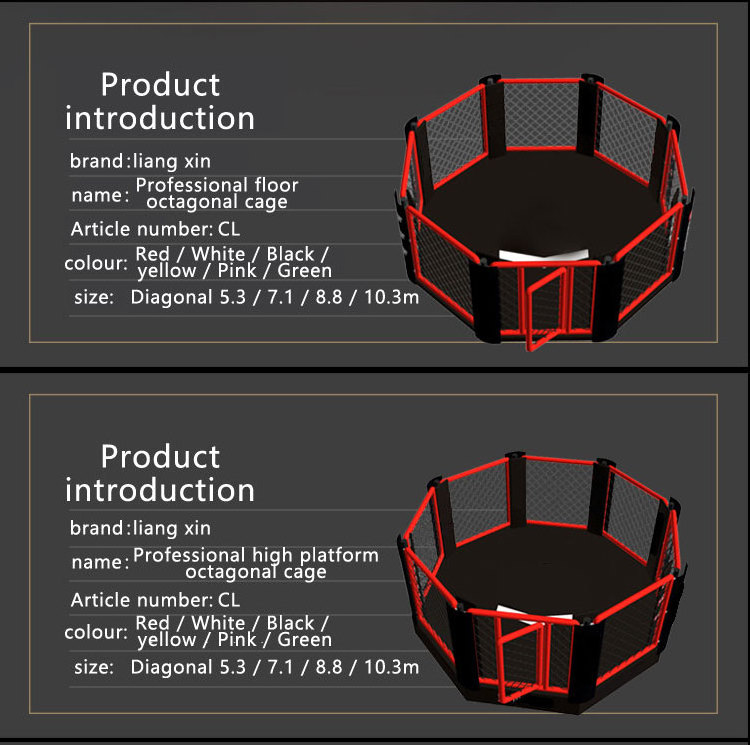

CUSTOM FLOOR MMA CAGE - 5m, 6m, 7m, 8m, 9m

- Morgan's floor mounted MMA cage is attached to the floor

- The MMA cage consists of 8 x high quality steel posts that are powder coated black crinkle finish

-

Each post weighs approximately 40kg

MMA cage consists of:

- 8 x heavy duty steel posts (floor mounted)

- 8 x heavy duty coated cage panels 1.8m tall

- 8 x wide post pads to cover all post sections of the cage: Vinyl with foam filling and easy Velcro closure

- 36 x 25mm EVA foam jigsaw mats for under floor padding

- 1 x non slip canvas for the floor of the MMA cage

- All the posts and panels are covered with foam and Vinyl for maximum safety for users

- The door of the MMA Cage has heavy duty steel hinges with a solid steel locking bar

- Installation time approx: 4-5 hours: 2 people minimum

Custom sizes: any size is available along with competition cages please enquire via email.

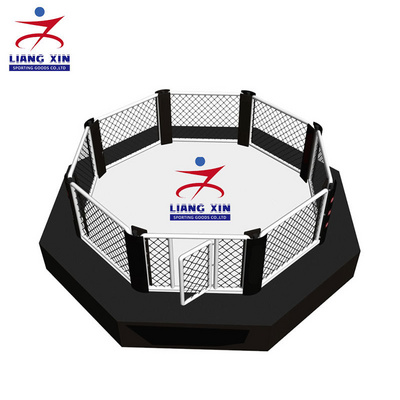

CUSTOM RAISED MMA CAGE - 5m, 6m, 7m 8m

- Morgan freestanding MMA octagon comes complete with a self-supporting frame that is completely padded for safety using composite sponge foam with a easy to clean Vinyl covering

- The floor is also covered in Vinyl that is easy to keep clean

- 1" plywood flooring with a 2cm EVA sponge for impact absorption

- Ideal addition to any gym, martial arts centre or MMA centre

- YOUR CUSTOM CLUB LOGOS CAN BE ARRANGED AT NO EXTRA COST

- The mma cage consists of 8 x high quality steel posts that are powder coated black crinkle finish

- Each post weighs approximately 40kg

- MMA cage consists of:

- 8 x heavy duty steel posts

- 1" plywood flooring with a 2cm EVA sponge for impact absorption

- 8 x heavy duty coated cage panels 1.8m tall

- 8 x wide post pads to cover all post sections of the cage: Vinyl with foam filling and easy Velcro closure

- 1 x non slip canvas for the floor of the MMA cage

- 1 x vinyl skirt where you can print your logo

- 1 x walk in ladder (size of ladder depends on height of cage)

- All the posts and panels are covered with foam and Vinyl for maximum safety for users

- YOUR LOGOS CAN BE PRINTED WHERE YOU WANT!

pad; material for pole pad cover; hardness and density of the foam inside the pad

7. Skirt

Type of material; Is it stretchable.

Let us know if you like to have our specs to answer all the above questions. We will be happy to show you what you will pay for.

Is it Easy to Assemble?

Very important question. Our answer is certainly YES. Assembly manual is available upon request.

Floor cage - 2 men in 1 hour

Elevated Cage - 3 men in 4 hours

Elevated Cage with Catwalk - 3 men in 6 hours

Don't expect to take it down and put it back in half an hour. Remember it is a 2-ton monster

How is it packaged when you ship?

Certainly we pack it to as small size as possible. Ever bought furniture from IKEA? Not a question, right?

How is it shipped?

By the cheapest means for sure, either by ocean or by truck if no sea port near you. Don't expect it to be shipped by air unless you own a bank.

What are your warranties?

We promise only what we can do, here' it is:

1.We delivery all the parts listed in our sales agreement; Anything missing, if ever happened,

we ship to you for free;

2.All materials we use meet our specifications; NO thinner mat; NO thinner vinyl;NO thinner wall steel;

NO thinner wood board and NO smaller size. We want you come back. You got it

3.In 10 years, no welding joins break; no steel pipes break, no steel plates break. This is a no brainer;

how could they break

4.In 5 years, all foams (on floor, rails, poles, pads) remain 90% of elasticity;

5.In 2 years, no breaks on vinyl bonding and stitches;

All warranties are valid under normal use condition

Still wondering how we produce a cage?

Come see our process:

1. Foam Cutter

for cutting octagon shape floor mats and rail and pole padding.

2. Vinyl Cover Heat Bonding

our house-made bonding machine.

3. Wood Cutter

professional wood lathe machine capable to cut to any angle in precision of 1mm

4. Vinyl cutting

professional fabric cutting machine to cut vinyl strips for rail and pole padding wrap.

5. Welding

carbon-dioxide arc welding machine

6. Wire mesh fixing

in-house made fixture to fix the wire mesh onto the steel frame very tightly;

7. Steel cutting

precision steel cutting machine cut to any angel and in precision of 0.1mm;

8. Die Cutter

heavy duty die cut press to cut profile shape vinyl for panel rail corner wrap;

9. Foam tube make

in-house made machine to produce XPE foam pipe from XPE sheet for panel rail padding.

There are more details that we can only show you when you visit our factory. We want to demonstrate that every little part of a cage is produced with engineering precision and personal passion. Wherever it ends up at it exceeds expectations.

Now how much is a FIGHTERS Cage?

Before we quote accurate price, we need to know:

1.Type of cage (floor cage, elevated cage, elevated cage with catwalk)

2.Cage size in meter either pole-to-pole or wall-to-wall

3.Sear port near you or delivery address

4.Printing file with printing size and colors