NaN / 0

Energy saving Automatic EPS Foam Icf Block Insulation Machine eps shape molding machine

Get Latest Price

US$ 25000

≥1 Sets

US$ 22000

≥3 Sets

US$ 21000

≥100 Sets

Quick Details

Place of Origin:

Zhejiang, China

Brand Name:

Milon

Machine Type:

EPS Shape Molding Mchine, Energy Saving Eps Foam Pallet Automatic Shape Moulding Machine

Voltage:

380V Or Customized

Product Details

Product Description

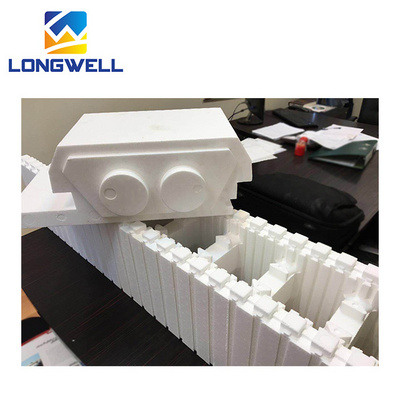

Energy saving Automatic EPS Foam Icf Block Insulation Machine eps shape molding machine

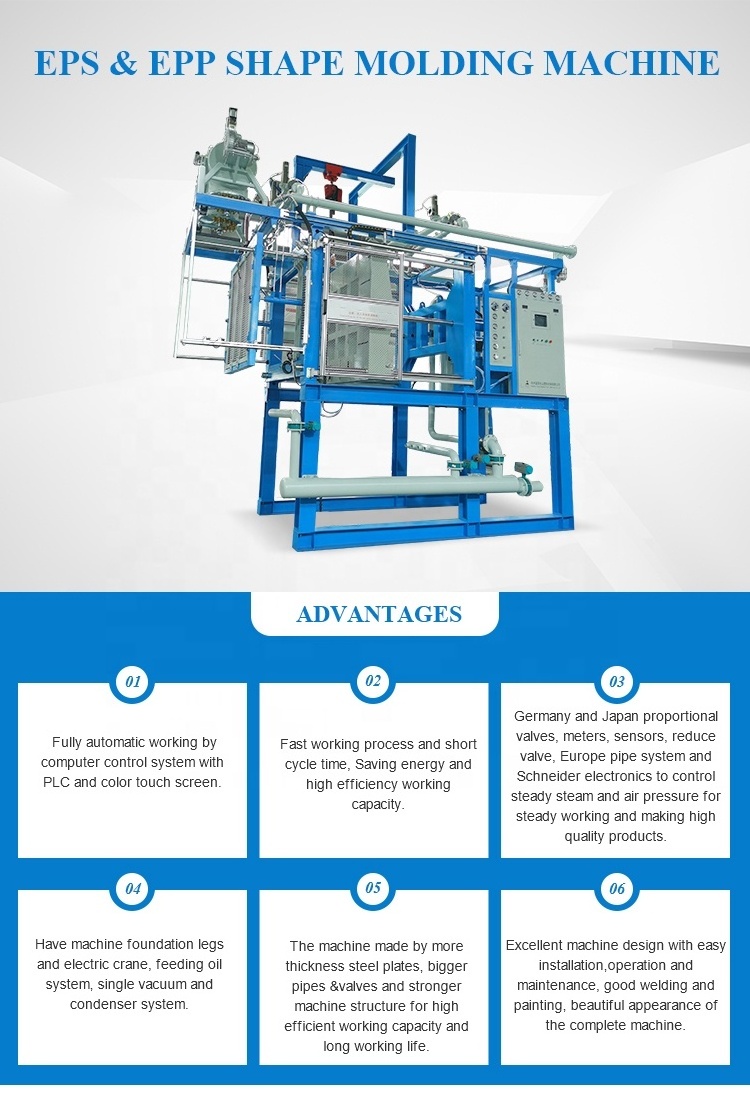

1. This machine applies

PLC program control and touch screen

human-machine control, low voltage and high efficiency special forming process control software that can produce a variety of products. Advanced molding technique and can produce various shapes of EPS products.

2. This machine can provide different kinds of foam articles with lower moisture content, high foaming speed and lower consumption of energy.

3. There are four kinds of operating mode

(Automatic, Semi-automatic, Middle-startup and Manual operation)

with safe-guard protective device to ensure safe operation.

4. This machine can choose

vacuum condensation spray system

which can significantly improve the efficiency of the vacuum function to achieve saving energy, guaranteed to work properly pressurized water tank under low pressure condition. This machine has

microcomputer control and touch screen display

. It can function high efficiently under computer control and management with high automation. Simplicity of operation and easy to maintain, it can reduce the labor intensity.

5. This machine applies advanced

electrical and hydraulic integration system

, which improves the moulding speed, lowers the energy consumption remarkably and reduces the environmental pollution.

6. The vacuum system can accelerate moulding speed,reduce cooling time and reduce moisture content of the product.

7.

Perfect failure-self-diagnosing and overloading protection system

. Auxiliary relay to ensure the safety of PLC and touch screen.

8. The moulding frame of FAV1400B is compatible from 1000 to 1400mm type, FAV1750B is compatible from 1400 to 1750mm type.

|

Welcome to learn us more, please to click:

Hangzhou Milon Machinery Co., Ltd.

|

|

|

|

|||

Hot Searches