NaN / 0

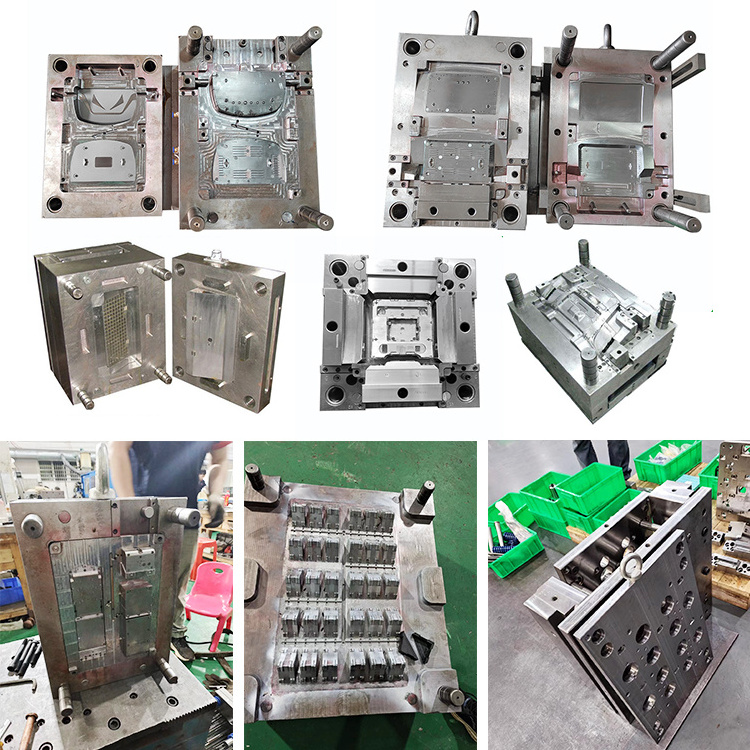

plastic injection mould service china manufacturer plastic injection mold maker

Get Latest Price

US$ 5

≥1 Pieces

US$ 0.3

≥10000 Pieces

Quick Details

Shaping Mode:

Plastic Injection Mould

Place of Origin:

Guangdong, China

Brand Name:

MOGEL

Model Number:

MP014

Product Details

plastic injection mould service china manufacturer plastic injection mold maker

Product Description

| Description of product |

| Product range | Mold design, mold making and produce plastic parts |

| Processing Craft | Mold fabrication, Injection etc; |

| Material | ABS,BMC, SMC, AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

| Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

| Color | RAL/PANTONE color |

| Size | according to the drawing |

| Mold Standard | DME,LKM,FUTA,HASCO etc. |

| Advantages | Competitive price & Fast Delivery & Good quality |

| Mould Base | as per customer's requirement |

| Delivery time | 10-15 days after placed order |

| Tolerance | 0.01~0.1mm; |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC,FQC,QA |

| Application | All kinds of plastic injection parts being used in a variety of industrial application. |

| Service |

Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Product details |

Design:

We have professional engineers design team,and can use CAD, Pro-E,UG,Solidworks etc.

Before the project started:

1, If you have 3D STEP/IGES/X_T drawing or 2D drawing, please directly send to us before quotation, then we will do DFM and mould design for you.

2, If you have samples no drawings, please directly provide us samples, we can design 3D for you,and quotation.

plastic injection mould

quick access to die & product quotes

the error between the mold quotation and the traansaction price is within

20%

injection molding price error within

10%

our price is transparent,which means the cost can be disclosed to you.

the engineering consultant will work with you to analyze the quotation structure and get your product development cost budget as soon as possible.price of raw materials,processing costs,plastic yuan.

For our new customers,we will promise the following preferential services.

1.Provide mould flow analysls for free

2.The shipping cost of sample proofing returned after placing the order*2

3.The cost of molds can be returned if the cumulative quantity of ordered production reaches the negotiated quantity:

4.Delivery time guarantee:1percent of the payment for one week's delay in mold making will be deducted as compensation,2 percent for two weeks, and the highest amount shall not exceed 10percent.

About plastic injection molding parts

.

We offers comprehensive custom plastic injection molding services to a wide range of industries. From low volume work to high volume production runs, we have the expertise and facilities to meet our customers’ contract manufacturing needs. Our comprehensive plastic injection molding abilities include machines with clamping forces from 80 to 1200 tons, allowing us to produce nearly any plastic part including micro parts, thin-walled parts, and large components that require multiple shots.

We can source and mold any grade of material from typical commodity grade plastics, to engineering, functional, and structural grade materials in a variety of colors and formulations. In addition to injection molding, we offer many secondary services including sonic vibration, RF welding, hot stamping, etching, printing, plating, and packaging. Our manufacturing processes are highly automated, which allows us to run a precise and efficient production floor with minimal overhead costs. These capabilities allow us to provide fast and cost competitive manufacturing services to our customers without sacrificing precision and quality.

| Production Process |