NaN / 0

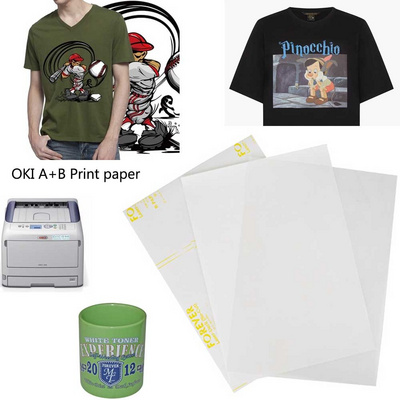

C711WT oki laser printer Self-Weeding Laser Dark Transfer Paper/ T-shirt transfer paper

Get Latest Price

US$ 1.19

≥500 Sets

Quick Details

Material:

White Paper

Application:

clothing,leather,textile

Type:

Heat Transfer

Place of Origin:

Shanghai, China

Product Details

Product Description

C711WT oki laser printer Self-Weeding Laser Dark Transfer Paper/ T-shirt transfer paper

Specification:

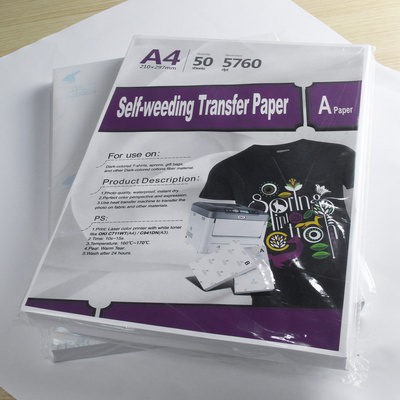

2.Size :A4, A3

3 .Package : 5 0 sheets/pack,Neutral packing

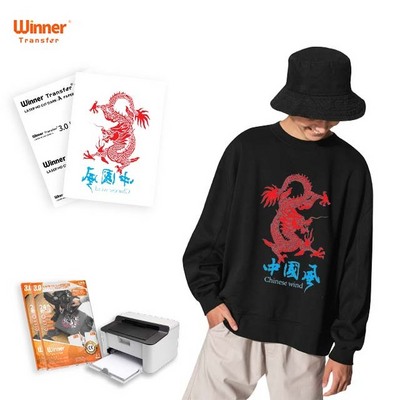

4.self weeding no cut laser transfer paper use for black cotton color clothing,

5 dark heat transfer paper use for other color clothing.

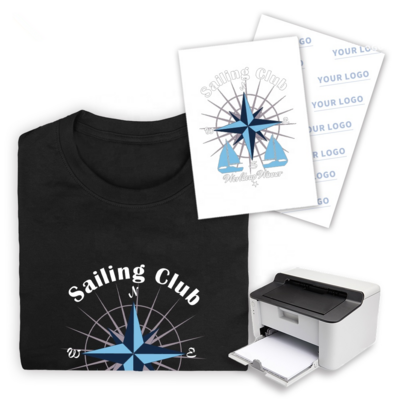

6 Use heat press machine to transfer T-shirt

7 High effective,color keep for longtime.

Features:

1 . Photo quality , waterproof , instant dry

2 . Perfect color perspective and expression

3 . Use heat transfer machine to transfer the photo on fabric and other materials

4 . Suitable for laser printer with white toner ,like oki.

5 . Packing:In cartons

Transfer process:

1, Pre-printing

a, The selection of laser printer and the heat press machine.

OKI C711WT is the best choice for the good transfer efficiency.

For the Heat Press Machine, we recommend you Swing Away Heat Press Machine.

b, Self-weeding have A ( Blue Back Label) and B (Gray Back Label).

c, B(Gray Back Label) has a layer of white film on the surface, and the size is smaller than A(Blue Back Label), so that we can peel B off A smoothly.

d, We should choose “ Heavy ” in print attribution.

e, Please adjust the temperature to 160℃-170℃ and the time to 60s-90s , finally depending on your own press machines.

2, Transfer Steps

a, Print the picture on the front side of A.

b, Put B front onto A front, then overlap.

c, Adjust the temperature to 160℃ -170 ℃ and the time to 60s-90s. When time’ s up, peel B off A rapidly without leaving the flat (Hot Tear). If there has remaining glue on the edge of A, you need to cut off.

d, Reset the temperature to 160℃ -170 ℃ and the time to 10s-15s, then put the T-shirt onto the flat and put A(Printing Side) onto the T-shirt. When time’ s up, after several seconds, peel A off the T-shirt.(Warm Tear)

e, Reheat the T-shirt in finished pic for 5s with a piece of oil paper.

Samples

We provide free sample for your test , and the shipping cost is payed by your side ( W.U or Paypal )

Samples will be send out within 2-3 days after we receive your payment .

PAYMENT

FAQ

What's the different between sublimation paper and transfer paper?

1. Definition:

1.Sublimation paper is applicable to sublimation transfer, on which can print images with mirror reversal through inkjet printing, flat printing, screen printing and gravure printing. Then transfer the image onto media by heating and pressuring, which can make ink on the paper become gaseous state and combine with the media.

2.Heat transfer paper is applicable to heat transfer, on which can print images through flat printing or gravure printing, and then combine with media by heating and pressuring in order to transfer image onto media.

2. Ink:

Sublimation paper usually use with sublimation ink.

Heat transfer paper usually use with sublimation ink, pigment ink, solvent ink or others.

3. Media:

Sublimation paper can be transferred onto polyester, mouse pad, banner and hard surface, such as mug, ceramic and aluminum plate. But heat transfer paper is usually transferred onto cotton.

Hot Searches