NaN / 0

granny flat prefabricated myanmar low cost prefab modular shipping cargo sea container house mobile homes

Get Latest Price

US$ 1799

≥1 Sets

US$ 1789

≥15 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

DINGRONG

Name:

granny flat prefabricated myanmar low cost prefab house mobile caravan

Keyword:

myanmar low cost prefab house

Product Details

granny flat prefabricated myanmar low cost prefab modular shippping cargo sea container house mobile homes

Product Description

contact us to get detailed information

some clients will say,i received quotation from another supplier,their price is cheaper than yours.

we know that our price is not the lowest in the market.in chinese prefab container house market,our price is a little lower than the middel price. most of our clients are distributors,so low quality materials with cheap price will not help distributor to get good reputation in local market,and very high quality materials with expensive price will not help distributor get big orders.

the difference of our materials from others are as follows

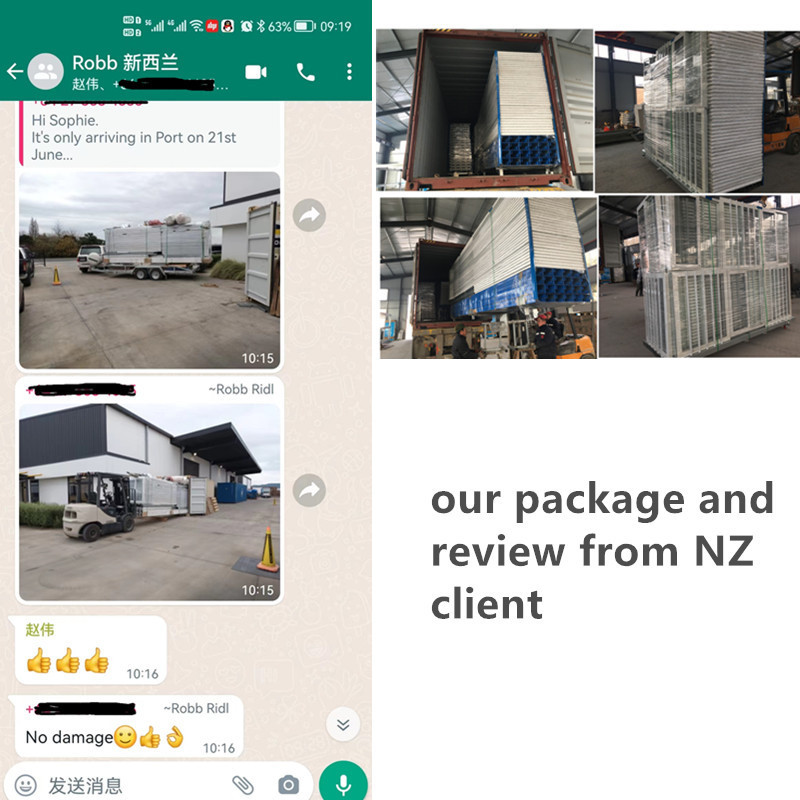

1.our package is steel pallet+plastic film,easy to load and unload,it is also a good way to protect the materials.our this kind package will increase around USD 70 cost per house. other suppliers usually load the materials pieces by pieces in container,to unload 1*40HC container,4 workers usually take one day.and the materials are easy to be damaged.

2.the container corner is welded by steel plate,so there are many welding points,although most of the supplier will do powder coating,the powder coating can not cover every welding points,half a year later,the corner will get rusted

our company does electroplating for the corner fistly,then do powder coating,this way makes it anti rust

3.we are using higher quality windows and doors,there are very cheap windows and doors in the market.we will not use these,because they are very fragile

other supplier's window and door

our window and door

4.most of the supplier are using common type MGO board,it is not very strong and not good for waterproof.our MGO board is with cement inside,it is new type subfloor material,strong and good for waterproof.

5.we are using higher quality sandwich panel,outer skin 0.4mm thickness,and some suppliers will use sandwich panel with double skin 0.3mm(although some supplier said their sandwich panel uses 0.3mm steel sheet,the exact thickness of the steel sheet is just 0.25mm,it is very thin,and can be easily damaged by a thief)

6.our column is made by bending machine which make the holes exact,and easy to install.now most of the supplier are making the column by cold forming machine,sometimes the holes are not exact,and hard to install

7.our bottom secondary beam is 14pcs(the space between two beams is around 380mm,the floor will not shake greatly),and most of the suppliers will use 9pcs(the space between two beams is around 570mm,the floor will shake greatly)

8.our frame without powder coating is 2.3mm,some supplier’s thickness is just 1.8mm,so they need to add support beam in the middle,the beam is thin,if without the support beam,the house will collpapse.

9.we are using new type ceiling panel which makes it more beatiful than others

This kind container house is designed from our collapsible container frame,the advantage is as follows

2. strong = main frame thickness is 2-3mm

3. with bigger size

standard flat pack container house is W2.25*L5.8*H2.60m or W2.438*L6.055*H2.6m

our this kind container house is with bigger size W3M*L5.95M*H2.8M

4. doesn't need a crane for installation as the 3m X 5.95m container house

is totally disasembled to easy handled sections and all that is required is re assembly.

5. they can be combined to make a bigger units or stacked 2-3 levels

6. widely used for accormmodation,office,bathroom etc

7.Because of big promotion now, these container houses are with a very competitive price

Container Engineering Report

Technical conditions

1.1 General Technical Condition

1)The structure can prevent the 8 magnitude earthquake.

2)The design of seismic grouping is the first group, the site characteristic cycle is considered 0.45s, the construction site category is considered by Class III, and the damping ratio of steel structure is 0.05. The maximum αmax of the horizontal earthquake influence coefficient is 0.04, which is calculated by 5 years.

3) Structural safety level is grade 2. The coefficient of importance is 1.0.

4) Conner fitting elevation plus or minus zero.

1.2 Materials

Normally,steel beams, steel columns, purlin are all used Q235B cold bending galvanized light steel.

strength of steel:f=215N/m2

1.3 Loading Combination

1.Calculation of floor Loading

(1)Bottom Flooring

Structure Weight 0.4 kN/m2

Dead Load Value 0.4 kN/m2

Live Load Value 3.0 kN/m2

(2)Roof board

Structure Weight 0.3 kN/m2

Dead Load Value 0.3 kN/m2

Live Load Value 0.5 kN/m2

2.Calculation of Wind loading

According to the 15 Design durable years, the basic wind pressure of wind loading is W0=0.3KN/m2

Packaging & Shipping

Special package way

almost all of the suppliers will load the parts of prefab house pieces by pieces in container.the sandwich panel is easy to be damaged we weld steel pallet on bottom,and wrape plastic film all around to protect the materials