NaN / 0

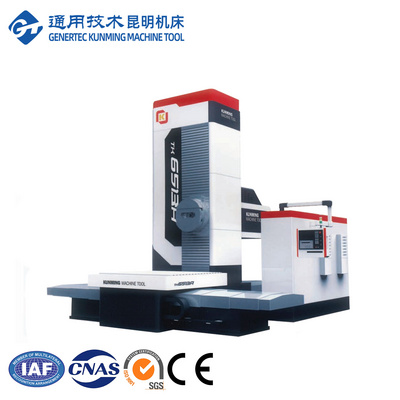

TPK611C Horizontal Boring Milling Machine/ China Heavy Horizontal Milling Boring Machine

Get Latest Price

US$ 40000

≥1 Pieces

US$ 39000

≥5 Pieces

Quick Details

Table Size (mm):

1320x1010

Table Travel (X) (mm):

1350 mm

Table Travel (Y) (mm):

1250 mm

Table Travel (Z) (mm):

900 mm

Product Details

Features:

The machine adopts the single vertical column and side hanging bin layout. And the worktable uses the CNC rotary worktable with 360 × 1 ° indexing.

X, Y, Z axes are controlled by the CNC system and could achieve linkage of three axes. The stretch-out and draw-back of boring axis and the rotation of the facing head use the servo motor to control and the automatic processing could be achieved.

X, Y, Z axes use the rectangular sliding guideway, Teflon plastic pasted process with the good vibration and high accuracy.

Headstock uses the heavy punch balance way. And the spindle and facing head are controlled by the AC servo motor.

Technical Parameter :

|

Model |

|

|

Max. Load of table |

2500kg |

|

Max. Allowable torque of spindle |

1100N.m |

|

Max. Allowable torque of facing plate |

1100N.m |

|

Max.axial feed resistance of spindle |

13000N |

|

Spindle speed step |

No step |

|

Face plate speed step |

No step |

|

Spindle speed range |

12-1100r/min |

|

Face plate speed range |

4-130r/min |

|

Rapid feed of spindle axis |

3600mm/min |

|

Rapid feed of face plate radial tool holder |

1180mm/min |

|

Spindle dia. |

110mm |

|

Table size (L×W) |

1320×1010 mm |

|

Max. distance from spindle axis to table surface |

905mm |

|

Min. Distance from spindle axis to table surface |

5mm |

|

Vertical travel of spindle box |

900mm |

|

Spindle travel |

550 mm |

|

Facing plate tool holder’s radial travel |

160 mm |

|

Longitudinal travel of table |

1350 mm |

|

Cross travel of table |

1250 mm |

|

Max. Boring dia. of spindle |

φ240 mm |

|

Max. Maching dia. of facing head |

630 mm |

|

Max. Drilling dia. |

φ50 mm |

|

Spindle taper |

BT50 |

|

Main motor power |

11/15kW |

|

X,Y,W rapid feed speed |

5000mm/min |

|

Overal dimension(l×w×h) |

|

|

Machine weight |

12300kg |

|

Positioning accuracy |

0.04/500mm |

|

Repeat positioning accuracy |

0.015/500mm |

Hot Searches