NaN / 0

YFMB- 540 Semi Automatic Small 490 Hot Press Lamination Laminating Film Machine for Laminates

Get Latest Price

US$ 8000

≥1 Sets

Quick Details

Packaging Type:

Barrel, Belt, Bottles, CANS, Capsule, Cartons, case, Film, Foil, Pouch, Stand-up Pouch

Packaging Material:

Glass, Metal, Paper, Plastic, Wood

Driven Type:

Electric

Voltage:

380V/220V

Product Details

Product Overview

YFMB-540 Semi-automatic Film Laminating Machine

Semi-Automatic laminating Machine is suitable for producing business card, greeting card, this machine also can add foil stamping funtions or embossing.This machine is very functional. Price is competitive, low investment for the begining of enterpreneurs.

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Model

|

YFMB-540

|

|

2

|

Max paper size

|

540*760mm

|

|

3

|

Min paper size

|

210*270mm

|

|

4

|

Paper weight

|

105-500g/m2

|

|

5

|

Laminating speed

|

0-25m/min

|

|

6

|

Voltage

|

380V

|

|

7

|

Temperature

|

Room-130oC

|

|

8

|

Power

|

9kw

|

|

9

|

Total weight

|

1000kg

|

|

10

|

Overall dimension

|

3000*1450*1650mm

|

PRODUCT CONFIGURATION

·Omron frequency converter is equipped for infinitely variable speed, and the operator can change the machine' s speed easily and guarantee the machine' s running stable.

·One-piece construction design makes the machine run more stably, and lengthens the machine' s lifetime.

·Manual paper feeding.

·Magnetic regulating plate can be adjusted easily to regulate manual paper feeding.

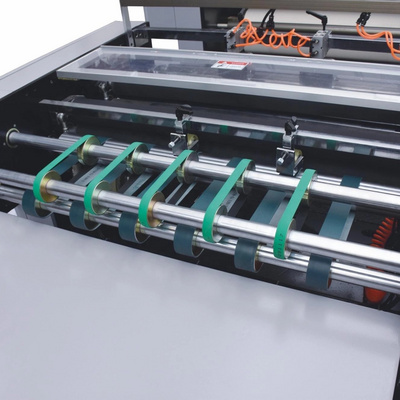

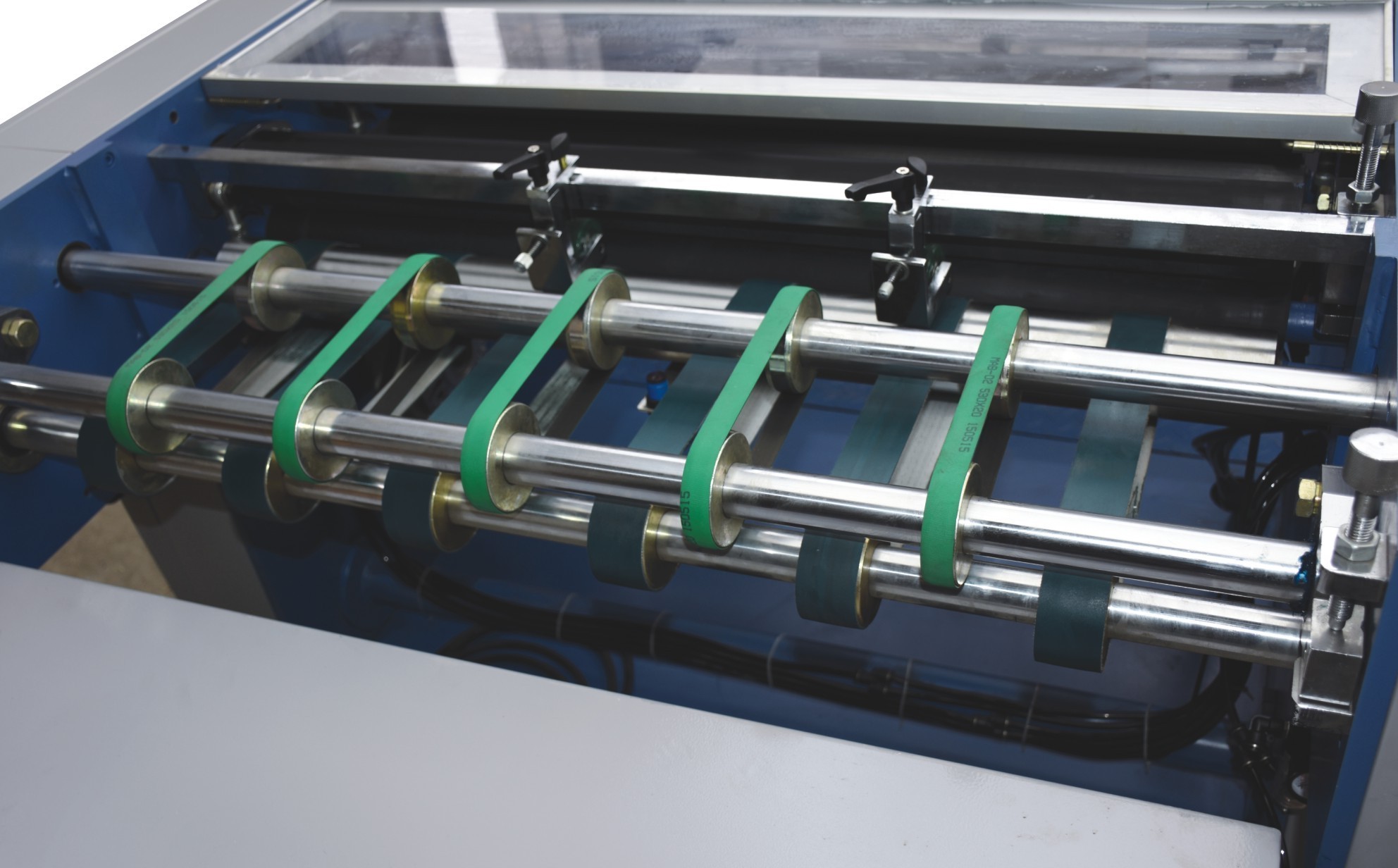

·High precision of chrome plated heating roller is equipped with built-in oil heating system, which has excellent performance to temperature control. The laminating temperature is adjustable upon applications.

·Hydraulic pressuring system provides big and steady pressure to guarantee good laminating quality.

·Air expansion shaft releases film, and precisionizes film release, and also makes the loading and unloading of film roll more convenient.

·The combination of air expansion shaft and braking device can adjust film release tension and speed.

·Film cutter cuts film width to make it meet paper size. The cut film is left on the film release spindle.

·Film perforating wheel perforates film edge for the automatic cut of laminated paper.

·Anti-curvature device: when going through anti-curvature device, the laminated paper shall be leveled at once and wont curve again after cut.

·Pneumatic cutting system realizes automatic paper cut as long as the operator inputs the workable paper size on the text screen.

·The cut paper is sent to paper receiving table. And the table height is adjustable upon applications.

·One-piece construction design makes the machine run more stably, and lengthens the machine' s lifetime.

·Manual paper feeding.

·Magnetic regulating plate can be adjusted easily to regulate manual paper feeding.

·High precision of chrome plated heating roller is equipped with built-in oil heating system, which has excellent performance to temperature control. The laminating temperature is adjustable upon applications.

·Hydraulic pressuring system provides big and steady pressure to guarantee good laminating quality.

·Air expansion shaft releases film, and precisionizes film release, and also makes the loading and unloading of film roll more convenient.

·The combination of air expansion shaft and braking device can adjust film release tension and speed.

·Film cutter cuts film width to make it meet paper size. The cut film is left on the film release spindle.

·Film perforating wheel perforates film edge for the automatic cut of laminated paper.

·Anti-curvature device: when going through anti-curvature device, the laminated paper shall be leveled at once and wont curve again after cut.

·Pneumatic cutting system realizes automatic paper cut as long as the operator inputs the workable paper size on the text screen.

·The cut paper is sent to paper receiving table. And the table height is adjustable upon applications.

Pre-regulator System

Paper manual feedingAutomatic Overlap Paper

Paper manual feedingAutomatic Overlap Paper

Corrugated Delivery

Corrugated delivery system collects paper easily, Also before this we set a function avoid paper be curled.

Operation Panel

According to paper thinkness or width, you can adjust through those switch to help machine work more stable.

According to paper thinkness or width, you can adjust through those switch to help machine work more stable.

Hot Searches