Customized according to your sample

Fully Automatic

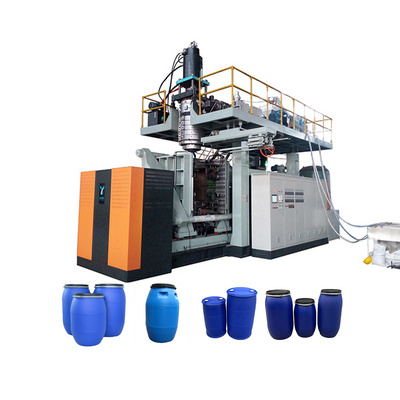

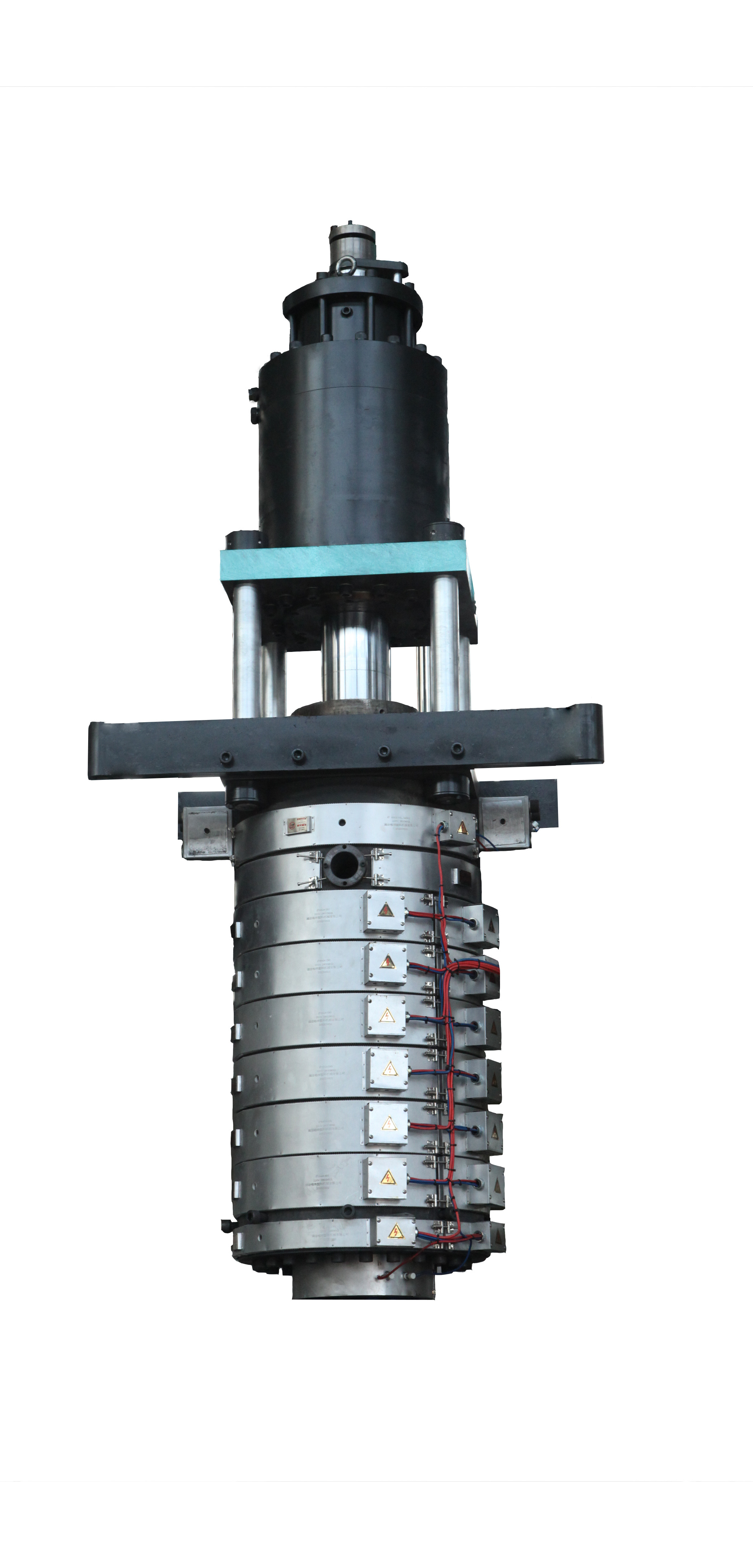

L-ring and Double L-ring drums blow moulding machine .This machine equipped with servo

system,patent screw and die head design,Moog parison control,optional from single to 3 layers machine to provide l

ower product costs but better quality.Our factory supports the low-end, mid-end and high-end machines under the guarantee of quality and service life

W

elcome for inquiry.