NaN / 0

best 3d printer pla filament best matte pla filament hdpe 3d printing filament

Get Latest Price

US$ 5

≥5 Rolls

Quick Details

Processing Service:

Moulding, Cutting

Place of Origin:

Zhejiang, China

Brand Name:

HAIKUN

Model Number:

HK-48815

Product Details

|

Name

|

3d printer filaments

|

|

Material

|

PLA / TPU / PCL / PETG

|

|

Filament

|

1.75mm/2.85mm/3mm (Diameter)

|

|

Colors

|

45 Colors and Luminous color |

|

Print temperature

|

195~220℃

|

| Feature | Custom colors, sizes and lengths accepted |

3D print filament offers several advantages in the realm of additive manufacturing. Firstly, it enables precise and intricate designs to be created with ease, allowing for complex geometries and fine details. Secondly, a wide range of materials, including ABS, PLA, and PETG, are available, providing versatility for various applications. Additionally, 3D print filaments are cost-effective, reducing the expenses associated with traditional manufacturing methods. Furthermore, it promotes sustainability by minimizing material waste. Overall, 3D print filament empowers efficient and customizable production, making it a valuable tool in the modern manufacturing landscape.

Characteristic:

(1) High strength, good toughness;

(2) Density is small, when printing larger volume model lighter, save money;

(3) Cost-effective, can be processed in wide range temperature;

(4) 1 kg /plastic spool packaging, can be automatic feed;

(5) To be applied to a variety of 3D printer, Makerbot, UP plus, Mendel, Prusa series, etc.

(6)PLA 3d printer filament: White, Black, Red, Blue, Green, Yellow, Orange, Purple, Pink, Grey, Transparent, Golden.....

Product Description

| Material | Specification | Printing temperature (°C) | Bottom plate temperature (°C) | colors in stock | advantage |

| PLA (including fluorescent/luminous) | 1. 75/3. 0 | 200-220 | 0-60 | 45 colors | Biodegradable / Odorless printing / No curling, no warping |

| PLA+ | 1. 75 | 190-210 | 0-60 | various colors | Better toughness, impact resistance and strength than ordinary PLA |

| Matt PLA | 1. 75 | 180-210 | 0-60 | 12 colors | Matte surface, beautiful texture |

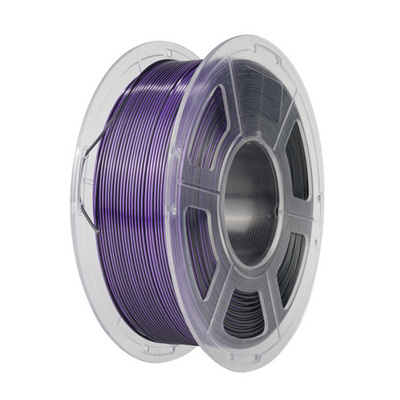

| siIk Rainbow | 1. 75 | 200-220 | 0-60 | How many colors are there in a roll of consumables / each roll has a different color | |

| Silk two-color/three-color | 1. 75 | 200-220 | 0-60 | Two-color/three-color (cross-section is two-color/three-color) | |

| ABS (with fluorescent/luminous) | 1. 75/3. 0 | 230-260 | 100-120 | 45 colors | Good plating performance/good toughness |

| HIPS (including fluorescent/luminous) | 1. 75/3. 0 | 230-260 | 100-120 | 19 colors | soluble in limonene |

| Change color (31°C color change) temperature-changing ABS | 1. 75/3. 0 | 230-260 | 100-120 | 4 colors | The color will change at different temperatures/change color at 31°C |

| Change color (31°C color change) temperature-changing PLA | 1. 75/3. 0 | 200-220 | 0-60 | 4 colors | The color will change at different temperatures/change color at 31°C |

| Light change color (color change under sunlight) light change ABS | 1. 75/3. 0 | 230-260 | 100-120 | 2 colors | change color in sunlight |

| Light change color (color change under sunlight) light change PLA | 1. 75/3. 0 | 200-220 | 0-60 | 2 colors | change color in sunlight |

| Nylon | 1. 75/3. 0 | 250-280 | 100-120 | Clear/White/Black | Good rigidity and resilience |

| PC | 1. 75/3. 0 | 250-280 | 100-120 | 4 colors | Rigid with toughness, temperature resistance 125°C |

| POM | 1. 75/3. 0 | 200-240 | 100-120 | white/black | Wear-resistant and twist-resistant, good insulation performance |

| PETG | 1. 75/3. 0 | 200-240 | 100-120 | 10 colors | Acid and alkali resistance/good toughness |

| Conductive ABS | 1. 75/3. 0 | 230-260 | 100-120 | only hee color | Effective release and prevent static electricity generation |

| Wood (based on PLA) | 1. 75/3. 0 | 180-195 | 80-100 | Natural wood color | According to the effect of near solid wood / can be nailed, drilled and carved. |

| Wood (PLA-based) | 1. 75/3. 0 | 180-195 | 80-100 | dark brown | According to the effect of near solid wood / can be nailed, drilled and carved. |

| PVA | 1. 75/3. 0 | 190-220 | skin color | water soluble material | |

| Flexible (TPU) | 1. 75/3. 0 | 200-220 | 60-80 | 23 colors | High softness, high elasticity/food grade/anti-aging (anti-UV)/printed upper and insole, aircraft model |

| Flame Retardant | 1. 75/3. 0 | 230-260 | 100-120 | white/black | fire protection |

| Metal | 1. 75/3. 0 | 200-220 | 0-60 | iron/steel/tungsten/copper | Corrosion resistance, good heat resistance. |

| Like silk | 1. 75/3. 0 | 200-220 | 0-60 | 12 colors | High gloss, easy to peel, smooth printing |

| 110°C PETG | 1. 75/3. 0 | 200-240 | 100-120 | Clear/White/Black | Acid and alkali resistance / good toughness / high temperature resistance 110 ℃ |

| PLA-Carbon fiber | 1. 75/3. 0 | 200-220 | 0-60 | only black | Matte black, high strength, low shrinkage |

| ASA | 1. 75/3. 0 | 230-260 | 100-120 | white/black | Anti-ultraviolet (anti-aging), temperature resistance 105°C |

| PLA Rain bow | 1. 75 | 200-220 | 0-60 | How many colors are there in a roll of consumables / each roll has a different color | |

| PC+ABS | 1. 75 | 230-260 | 100-120 | Natural color (off-white) | High hardness, good toughness, good rigidity |

| marble | 1. 75 | 200-220 | 0-60 | White | marble texture |

| Twinkling | 1. 75 | 200-220 | 0-60 | various colors | shiny surface |

| PETG-Carbon fiber | 1. 75/3. 0 | 200-240 | 80-100 | only black | Better toughness and strength than PLA-carbon fiber |

| PVB polishing consumables | 1. 75 | 190-220 | 0-70 | 4 colors | Polishability, not easy to warp, easy to print |

| PMMA (acrylic) | 1. 75 | 220-240 | 100-120 | Transparent/White | High optical clarity, good weather resistance, rigid |

| Advertising characters (luminous characters) indoors | 1. 75 | 200-220 | 0-60 | Shading and light transmission | Easy to print, good printing effect, good toughness, not temperature resistant. |

| Advertising characters (luminous characters) outdoor | 1. 75 | 240-260 | 55-75 | Shading and light transmission | High toughness, high strength, temperature resistance 75℃ |

more products

Related Products

Production Process