NaN / 0

China Factory Synthetic Metal Bond Industrial Diamond Powder 3040 Mesh MBD Diamond Powder for Marble Polishing Pad

Get Latest Price

US$ 50

≥1 Bags

US$ 45

≥10000 Bags

US$ 40

≥30000 Bags

Quick Details

Type:

diamond powder

Abrasive Grain Sizes:

30#-500#

Place of Origin:

Henan, China

Brand Name:

HNHONGXIANG

Product Details

Product Description

With vast manufacturing and marketing experience and knowledge, we are supplying the outstanding assortment of Diamond Micron Powder. The offered diamond powder is processed by utilizing finest quality diamonds and crystals as per current market standards. This diamond powder is demanded to polish purposes in jewelry, optical lenses, alumina ceramics, and hard alloy fields. This Micron Diamond Powder can be easily availed in several packaging options.

Features:

- High purity

- Irregular shape

- Uniform structure

- Good self-sharpness

- Narrow particle size distribution

Specifications:

GHDY grade

The powder comes structure from RVD grade diamond, the crystal of this kind of micron powder features irregular shape and sharp edges, the irregular structure can support diamond tools with an excellent grinding efficiency, the high friability can support diamond tools finish the best polishing application surface. It is suitable for producing resin bond, vitrified bond diamond tools or producing grinding wheel and diamond lapping paste.

Grit Size Available (mesh)

60/80,80/100,100/120,120/140,140/170,170/200,200/230,230/270,270/325,325/400,400/500,500/600.

| Grit | RVG | RVD | MBD0 | MBD1 | MBD2 | MBD3 | MBD4 | MBD5 | MBD6 | MBD8 | MBD10 | MBD12 | SMD25 | SMD30 | SMD35 |

| 30/35 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 35/40 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 40/45 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 45/50 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 50/60 | √ | √ | √ | √ | √ | √ | |||||||||

| 60/70 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 70/80 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 80/100 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 100/120 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 120/140 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 140/170 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 170/200 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 200/230 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 230/270 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 270/325 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 325/400 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 400/500 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

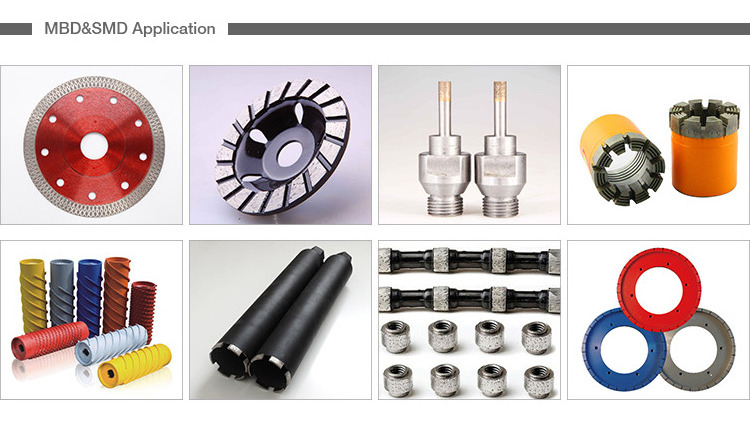

Products Recommend

Manufactured on the basis of the sharp diamond rawmaterial and undergoing several producing processes.Through the sharpening reprocessing, filtering out theslice and strip particles, to ensure the great crystal form,and meet the requirements about the high precisionsawing, lapping and polishing

Diamond Micron Powder Feature:

General grade diamond micron powder for multi-purpose Manufactured on the basis of the diamond industry standard, which is the multi-purpose product.

Relatively regular crystal form, good hardness and impact resistance, and few impurities, comparatively narrow particle size distribution.

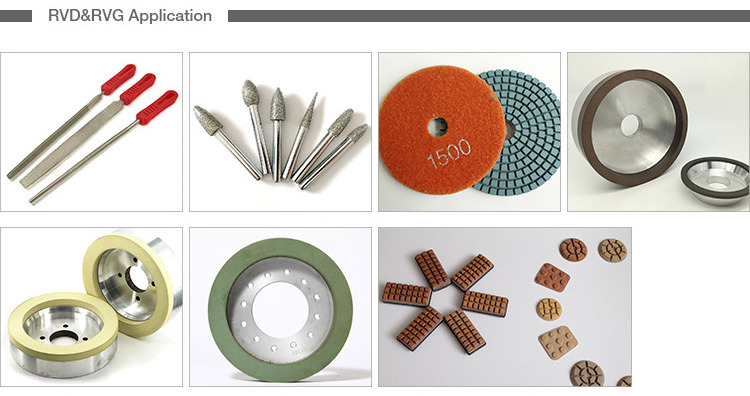

Diamond Micron Powder Usage :

for making the resin bond, vitrified bond or electroplated diamond wheels, diamond pads, diamond abrasive Fickert, diamond lappato, or diamond lapping paste, etc.Less Impurities and lowder magnetic.

Diamond Micron Powder Workpiece Material:

Aim of grinding and polishing glass, ceramic, stone, concrete, gemstone, hard alloy, wire die, sapphire, semiconductors, etc.

Diamond Micron Powder for Diamond Wire:

Diamond micron powder for diamond wire is specifically for silicon, sapphire cutting diamond wire saw. Through Yangge's control of particle size, removal of small particles and large particles in the product, the consumption of cutting materials is reduced, and the product quality and processing efficiency of the customer's products are improved.

Diamond Micron Powder for PDC:

Diamond micron powder for PDC, Based on high-grade wear-resistance and high-efficiency type, it is processed and processed to remove impurities from the product and maintain product purity.

It is mainly used in the production of polycrystalline diamond compact sheets.

| Standard of China | Standard of International | Mesh | D50um | Standard of China | Standard of International | Mesh | D50um |

| W0.25 | 0-0.25 | 60000 | 0.11~0.20 | W0.5 | 0-0.5 | 30000 | 0.20~0.30 |

| W1 | 0-1 | 15000 | 0.6~0.8 | W1.5 | 0-2 | 13000 | 1 |

| W1.5 | 1-2 | 12000 | 1.1~1.3 | W2.5 | 1-3 | 10000 | 1.6`1.8 |

| W3 | 2-3 | 7000 | 1.9~2.1 | W3.5 | 2-4 | 6500 | 2.2~2.6 |

| W3.5 | 2-4 | 6000 | 2.6~3.0 | W4 | 2-5 | 5000 | 3.1~3.4 |

| W5 | 3-6 | 4000 | 3.5~4.2 | W6 | 4-6 | 3500 | 4.4~5.0 |

| W7 | 4-8 | 3000 | 5.0~6.0 | W10 | 4-9 | 2500 | 6.1~6.5 |

| W10 | 5-10 | 2000 | 6.5~7.3 | W10 | 6-12 | 1800 | 7.3~8.3 |

| W12 | 8-12 | 1600 | 8.3~9.0 | W14 | 7-14 | 1500 | 9.1~10.5 |

| W14 | 8-16 | 1300 | 10.0~12.0 | W20- | 10-20 | 1200 | 12.5~15.0 |

| W20 | 12-22 | 1000 | 15.0~17.0 | W20+ | 15-25 | 800 | 18.0~20.0 |

| W28 | 20-30 | 700 | 20~23 | W28+ | 22-36 | 600 | 23~26 |

| W40- | 20-40 | 500 | 26~29 | W40 | 30-40 | 450 | 29~32 |

| W40+ | 35-45 | 400 | 32~36 | W50 | 36-54 | 37~43 | |

| 325/400 | 320 | 43~48 | 270/325 | 280 | 48~55 | ||

| 230/270 | 240 | 56~64 | 200/230 | 200 | 65~73 |

Hot Searches