NaN / 0

Pavement Automatic Hot Melt Road Marker Paint Thermoplastic Road Marking Machine

Get Latest Price

US$ 1602

≥1 Sets

US$ 1566

≥2 Sets

Quick Details

Place of Origin:

Guangdong, China

Brand Name:

NOKIN

Dimension(L*W*H):

1600*800*1200mm

Weight:

120 kg, 135kg

Product Details

Pavement Automatic Hot Melt Road Marker Paint Thermoplastic Road Marking Machine

Product Description

|

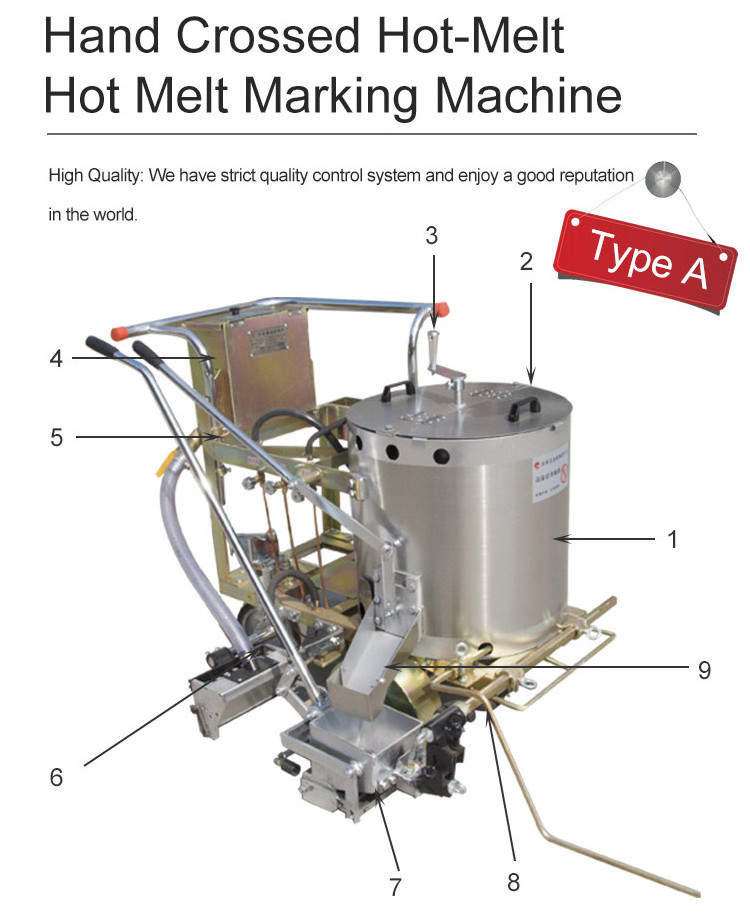

1, Stainless steel heat preservation kettle

|

2, Paint input door |

| 3, Liquefied petroleum gas valve | 4, Glass beads box |

| 5, Paint output door handle | 6, Road Marking bucket handle (to support) |

| 7, Hopper | 8, Pointing needle |

|

1, Stainless steel heat preservation kettle |

2, Crank |

| 3, Paint input door | 4, torches |

| 5, trunk | 6, Road Marking bucket handle (to support) |

| 7, Rear locator | 8, Glass beads box |

| 9, Fire road | 10, Knife |

| 11, Hopper(5.10.15.20.25.30.40.45cm) | 12, Pointing needle |

| 13, Hanger | 14, Paint output door |

NOKIN Hand crossed hot-melt hot melt marking machine are the key to construction equipment, used in conjunction with hot melt kettle, marking the completion of construction, manufacture of aircraft using special high-precision cast iron bucket line to ensure that the marking is zoned side on the first homogeneous, uniform thickness, linear appearance, landing knife can adapt to different situations of the road surface, glass beads spread complete with automatic speed control buffer devices, devices can be manually shifted curve achieve excellent construction, concrete marking, high-quality construction, construction fast, flexible operation, convenient maintenance and so on.

| Paint Barrels: |

double stainless steel heating insulation barrels, capacity 100 kg,

plug-in manually mixer devices, removable devices |

| Glass Bead Storage Box: | 10 kg / box |

| Glass Beads Sow Browser: | synchronous clutch spread with speed gearshift device |

| Marking Width: |

High-precision ultra-thin material manufacturing, scraper-type structure,

the standard configuration of 150 mm, Can provide 100-450mm |

| Landing Knife: |

Carbide, with eccentric sleeve device can adjust the thickness of the

scope marking :1-2.5 mm |

| Tire: |

Alloy Wheel Unit, a special heat-resistant rubber, after the last round

with positioning devices for the body along a straight line direction |

| Heating Method: | liquefied petroleum gas |

| Subscript Line Width: |

150 mm engineering requirements in accordance with the replacement

of different specifications crossed Doo |

| Size: | 1250 * 900 * 950 mm |

| Net Weight: | 110kg (242.5ib) |

| Paint Barrels: |

double stainless steel heating insulation barrels, capacity 100 kg,

plug-in manually mixer devices, removable devices |

| Glass Bead Storage Box: | 10 kg / box |

| Glass Beads Sow Browser: | synchronous clutch spread with speed gearshift device |

| Marking Width: |

High-precision ultra-thin material manufacturing, scraper-type structure,

the standard configuration of 150 mm, Can provide 100-450mm |

| Landing Knife: |

Carbide, with eccentric sleeve device can adjust the thickness of

the scope marking :1-2.5 mm |

| Tire: |

Alloy Wheel Unit, a special heat-resistant rubber, after the last round

with positioning devices for the body along a straight line direction |

| Heating Method: | liquefied petroleum gas |

| Subscript Line Width: |

150 mm engineering requirements in accordance with the

replacement of different specifications crossed Doo |

| Size: | 1200 * 900 * 950 mm |

Advantages

1, Bodywork legerity, compact structure, beautiful appearance .

2, Lifting type handlebar design, operator may adjust it according to the needs .

3, Glass beads automatic sown device.

4, Glass beads sown speed device, sets up 2 gear, according to demand to make adjustments.

5, Heat preservation ,heat barrel ,removable design, reasonable design, solve the stirring shaft of mixing paint

6, Adjustable pointer in order to improve work efficiency.

7, The company adopts high precision steel manufacturing and own high-temperature resistance, corrosion resistance, durable form etc.

8, Our company adopts cast-iron ,imported rubber to make the wheels flexible , strong and durable.

preparation work:

1. Please clean over the road to achieve marking requirements.

2. Spray some lubricants on the hopper and transmission system to ensure working flexible.

3. The first using time should remove sundry and filter inside kettle, be sure the rotating parts is flexible.

4. Carefully check all screws is tight.

5. Carefully check liquefaction tank, burner, pipeline is in good condition, and without leakage phenomenon.

6. Adjust cutting knife to make sure the line thickness between1.5-2.5 mm

7. Operators shall wear good labor protection supplies to present burning.

Related Products

About NOKIN

Send Inquiry