NaN / 0

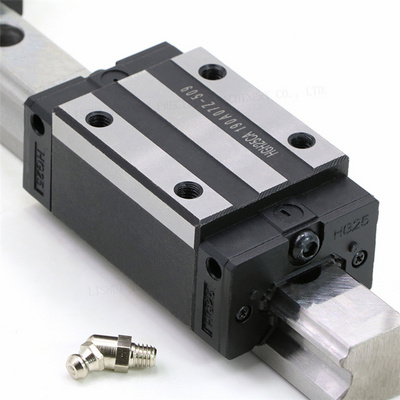

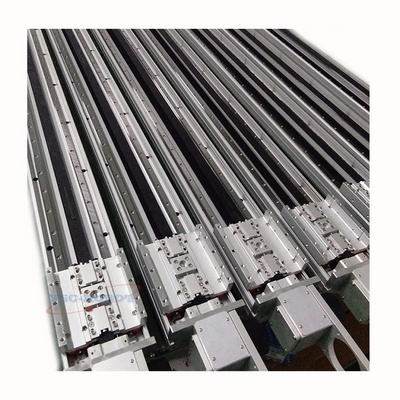

C5 Hiwin Ball Screw and Nut 1605 1610 CNC Linear Actuator Guide Rail 2000mm

Get Latest Price

US$ 500

≥1 Sets

US$ 300

≥2 Sets

Quick Details

Weight (KG):

7

Core Components:

High precision

Length:

1000mm, 1000 mm

Place of Origin:

China

Product Details

Imported Precision Ground Ball Screws Linear Guides

PRODUCT DISPLAY

High precision 3-axis component design, precise control of details

--------The positioning accuracy of all axes of the non linear direct measurement system is 3 µ m (based on ISO 230-2 standard)

--------C3 grade precision ball screw with excellent positioning accuracy

--------Steel sleeve support bearing, giving it high contact rigidity

--------Oil temperature cooling to ensure accuracy

--------C3 grade precision ball screw with excellent positioning accuracy

--------Steel sleeve support bearing, giving it high contact rigidity

--------Oil temperature cooling to ensure accuracy

PRODUCT INFORMATION

|

Main Specifiation

|

Unit

|

Parameters

|

|

Warranty of core components

|

months

|

3

|

|

Condition

|

|

NEW

|

|

Length

|

mm

|

1000

|

|

Biameter

|

mm

|

32

|

|

Weight

|

kg

|

10

|

APPLICATIONS

1. Box type parts

For example, car engine block and gearbox, machine tool spindle box, diesel engine block and gear pump housing. In addition, due to the high accuracy, high processing efficiency, good rigidity, and automatic tool changing characteristics of the machining center itself, as long as the process flow is properly formulated and reasonable specialized fixtures and tools are used, problems such as high precision requirements, complex processes, and improved production efficiency of box shaped parts can be solved.

4. Plate, sleeve, and plate parts

This type of workpiece includes plate-shaped parts with keyways and radial holes, with hole systems and curved surfaces distributed on the end face, or axial workpieces such as flanged shaft sleeves And plate shaped parts with more left-hand machining, such as various motor covers.

For example, car engine block and gearbox, machine tool spindle box, diesel engine block and gear pump housing. In addition, due to the high accuracy, high processing efficiency, good rigidity, and automatic tool changing characteristics of the machining center itself, as long as the process flow is properly formulated and reasonable specialized fixtures and tools are used, problems such as high precision requirements, complex processes, and improved production efficiency of box shaped parts can be solved.

2. Complex surface parts

Parts with complex curved surfaces in the fields of aviation, aerospace, and transportation, such as cams, integral impellers of aircraft engines, propellers, mold cavities, etc. The use of multi-axis machining centers, combined with automatic programming technology and specialized tools, can greatly improve their production efficiency, ensure the shape accuracy of curved surfaces,and make automatic machining of complex parts very easy.

Parts with complex curved surfaces in the fields of aviation, aerospace, and transportation, such as cams, integral impellers of aircraft engines, propellers, mold cavities, etc. The use of multi-axis machining centers, combined with automatic programming technology and specialized tools, can greatly improve their production efficiency, ensure the shape accuracy of curved surfaces,and make automatic machining of complex parts very easy.

3. Irregular parts

Heterogeneous parts are irregularly shaped parts that require multi station mixed processing of points, lines, and surfaces (such as brackets, bases, profiling, etc.). When processing irregular parts, the more complex the shape, the higher the accuracy requirements, and the more advantages the machining center can display.

Heterogeneous parts are irregularly shaped parts that require multi station mixed processing of points, lines, and surfaces (such as brackets, bases, profiling, etc.). When processing irregular parts, the more complex the shape, the higher the accuracy requirements, and the more advantages the machining center can display.

4. Plate, sleeve, and plate parts

This type of workpiece includes plate-shaped parts with keyways and radial holes, with hole systems and curved surfaces distributed on the end face, or axial workpieces such as flanged shaft sleeves And plate shaped parts with more left-hand machining, such as various motor covers.

5. Parts in the trial production of new products

When changing the machining object, only a new program needs to be compiled and input to achieve the machining. Sometimes,processing can also be achieved by modifying some program segments or using special instructions in the program. If the zoom function command is used, parts with the same shape but different sizes can be processed, providing great convenience for single piece, small batch, multi variety production, product modification, and new product trial production, greatly shortening the production preparation and trial production cycle.

When changing the machining object, only a new program needs to be compiled and input to achieve the machining. Sometimes,processing can also be achieved by modifying some program segments or using special instructions in the program. If the zoom function command is used, parts with the same shape but different sizes can be processed, providing great convenience for single piece, small batch, multi variety production, product modification, and new product trial production, greatly shortening the production preparation and trial production cycle.

COMPANY INFORMATION

PACKAGE& TRANSPORT

FAQ

1. How do you package?

According to the size of the machine tool and container specifications, small machine tools use wrapping film and customized wooden boxes, while large machine tools use wrapping film.

2. How should I pay for my order?

You need to pay 30% of the payment first before we can start production. After the machine is completed, we will send you pictures or videos, and you will need to pay the balance before shipping.

3. How long is the delivery time?

Regular Machines,We will delivery then within 20 working days after received your deposit,if some special machines will be some longer.we will give you the answer accordingly.

4. What is your minimum order quantity and warranty?

MOQ is 1 set, and warranty is one year.

5. What is your trade terms?

FOB, CFR, CIF or others terms are all acceptable.

According to the size of the machine tool and container specifications, small machine tools use wrapping film and customized wooden boxes, while large machine tools use wrapping film.

2. How should I pay for my order?

You need to pay 30% of the payment first before we can start production. After the machine is completed, we will send you pictures or videos, and you will need to pay the balance before shipping.

3. How long is the delivery time?

Regular Machines,We will delivery then within 20 working days after received your deposit,if some special machines will be some longer.we will give you the answer accordingly.

4. What is your minimum order quantity and warranty?

MOQ is 1 set, and warranty is one year.

5. What is your trade terms?

FOB, CFR, CIF or others terms are all acceptable.

Hot Searches