NaN / 0

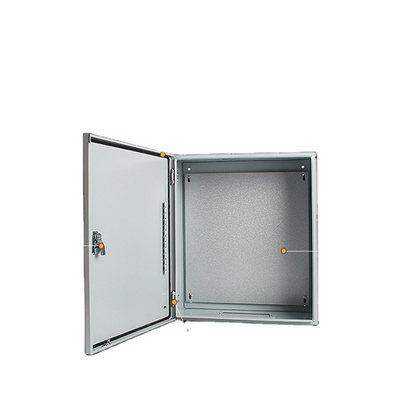

Outdoor waterproof sheet metal stainless steel aluminum electric enclosure meter junction metal box

Get Latest Price

US$ 25

≥100 Sets

Quick Details

Protection Level:

IP66

Type:

Control Box

Place of Origin:

Guangdong, China

Brand Name:

oem

Product Details

ISO 9001:2008 certified YOCO utilizes ongoing employee training, automation, continuous process improvement and innovation to maximize the quality, reliability, and cost-effectiveness of your components.

Parts are carefully examined throughout the production process at multiple quality control checkpoints and all shipments are thoroughly tested and inspected before they are released to your facility. As a result, our team has been able to consistently maintain a nearly 0% external part reject rate that has enabled many of our customers to eliminate the costly and time eroding process of inbound part inspection.

We have a full-time AWS certified inspector and each of our welders is qualified to one or more of the following specifications and/or codes:

AWS D1.1-Structural Welding Code-Steel

AWS D1.2-Structural Welding Code-Aluminum

AWS D1.3-Structural Welding Code-Sheet Steel

AWS D1.6-Structural Welding Code-Stainless Steel

AWS D14.3-Specification for Welding Earthmoving Construction and Agricultural Equipment

AWS D15.1-Railroad Welding Specification for Cars and Locomotives

EN 287-1-Qualification Test of Welders-Fusion welding-Part 1: Steels

DIN EN 15085-Railway Applications. Welding of Railway Vehicles and Components.

Customer specific welder qualifications.

| Material available | Stainless steel 201/304/316, sheet metal ( SPCC, SECC), aluminum alloy etc. | ||

| Fabrication service | Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, machining, surface treatment, and other General Fabrication Service | ||

| Surface Treatment | Powder coating, Zinc plating, chrome plating, hot-dip, Silkscreen, polishing and so on. | ||

how can I get a quotation, is it free?

send us the design drawings or samlpe. free quotation will be prepared immediately.

what is the process to place the order?

1. send us the drawings to get a free quotation.

2. we will make a sample for you to check the quality.

3. batch production will be proceed after sample is qualified and our service is accepted.

2. we will make a sample for you to check the quality.

3. batch production will be proceed after sample is qualified and our service is accepted.

the surface treatment type we can handle?

Powder coating, paint, polish, brushed, galvanized, anodized.sand blasting.

Hot Searches