NaN / 0

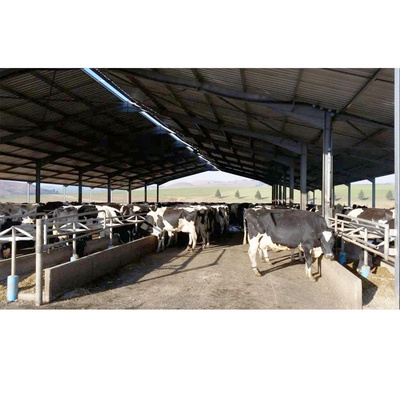

Fast construction low cost prefab light steel structure cattle cow goat sheep shed for sale

Get Latest Price

US$ 25

≥100 Square meters

US$ 20

≥2000 Square meters

US$ 15

≥10000 Square meters

Quick Details

Grade:

Steel

Tolerance:

±1%

Place of Origin:

Shandong, China

Brand Name:

Juhe

Product Details

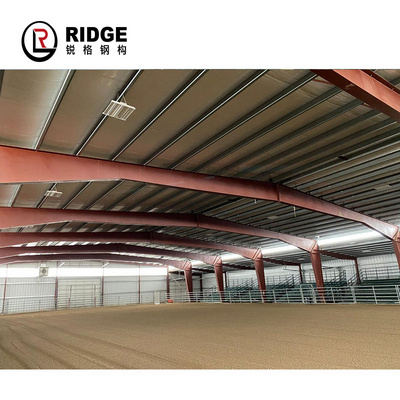

Team Design

Sheep house construction

JUHE offers a global "turnkey" solution, where designing, building and installing undergoes precise operation. Where all the parties involved work in constant collaboration the livestock farm can exceed expectations. We are always available to adapt to the particular conditions each project, animal and farmer requires.

|

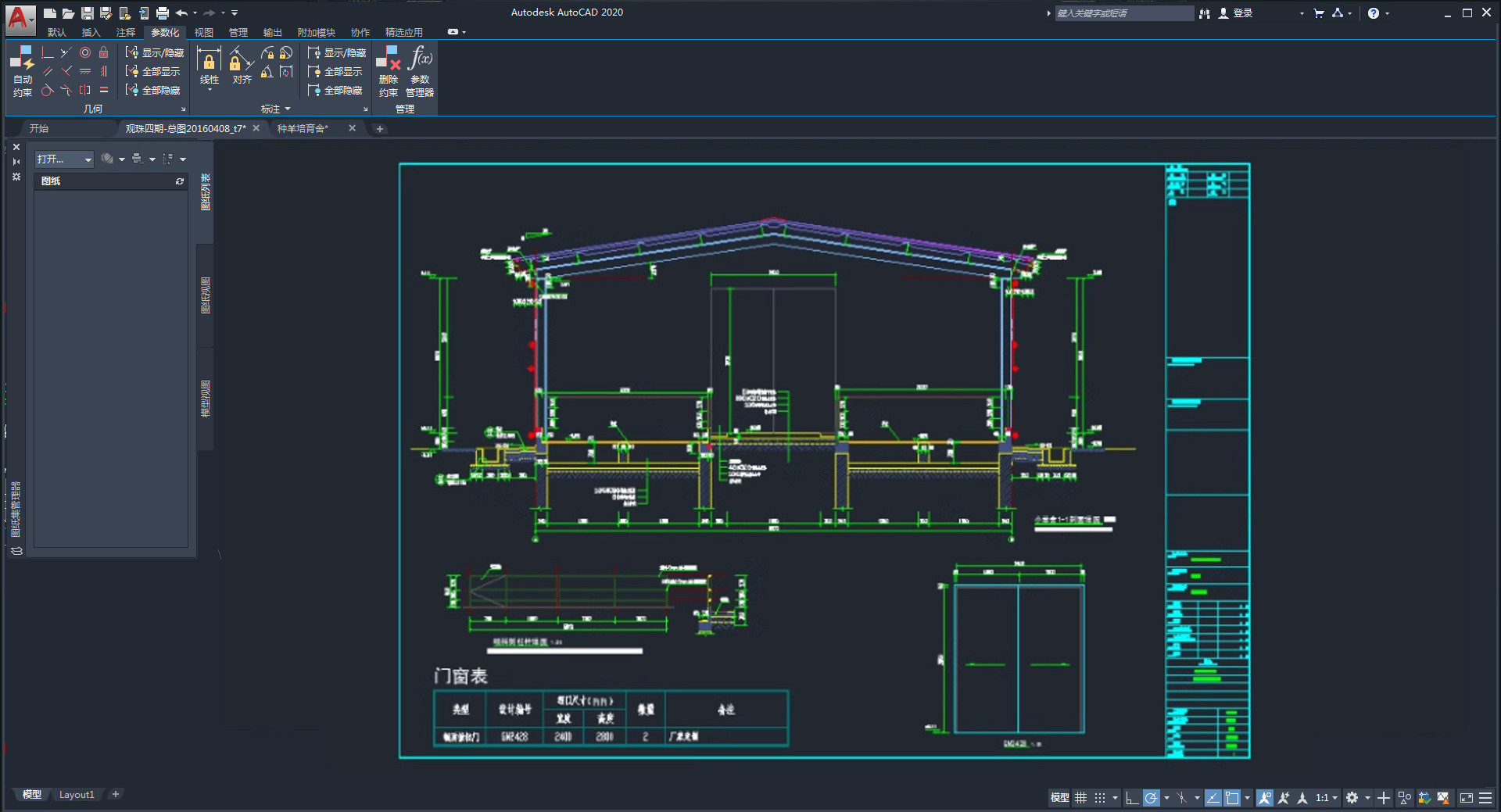

Main Structure

|

|

|

||

|

No

|

Category

|

Description

|

||

|

1

|

Main structure

|

Steel (Q345B)

|

||

|

2

|

Second steel structure

|

Steel (Q235,painted or galvanized)

|

||

|

Maintenance

|

|

|

||

|

No

|

Category

|

Description

|

||

|

3

|

|

0.5mm/150 Fiber Glass / 0.5mm sandwich panel

|

||

|

|

|

840 type steel tile, thickness 0.5mm

|

||

|

4

|

|

0.5mm/150 Fiber Glass / 0.5mm sandwich panel

|

||

|

|

|

840 type steel tile, thickness 0.5mm

|

||

|

5

|

Windows

|

Plastic steel window / Aluminium alloy window

|

||

|

6

|

Doors

|

EPS composite board sliding door / Roller door

|

||

|

Fittings

|

|

|

||

|

No

|

Category

|

Description

|

||

|

7

|

Edge cover

|

Steel sheet , thickness 0.5mm

|

||

|

8

|

|

M24 embedded bolt

|

||

|

|

|

Intensive bolt

|

||

|

|

|

Galvanized ordinary bolt

|

||

|

9

|

Daylighting band

|

1.2mm glass reinforced plastic

|

||

Manufacturing Construction

Baishengjuhe been appointed by Harry to design and construct a new, state of the art sheep house and handling facility at the Farm Centre, in Uruguay.

Steel structure goat sheep farm design should fall in the high and dry, good drainage, sunny place. Sheep pen on the ground more than 20 centimeters of above ground. The total demand is strong, warm and well ventilated.

The area according to the feeding size of the barn, general each sheep to guarantee 1. 0 to 2. 0 square meters. Each sheep house can't ring a lot of sheep, or a bad management, and increases the chances of infection. Feeding sheep, for the convenience of management, should establish the breeder channel, channel on both sides of the separated by reinforcing bar or wood pole, sheep eating and drinking water, from the rail head eating or drinking water.

Installation and Debugging

WAILTHROUGH FEEDERS

At lambing time, to using the eight pens and splits up ewes based on how many lambs they are carrying. To ensure he had plenty of feed space, particularly concentrate feeding space, incorporated walkthrough feeders in between the pens.

FENCE AND RESTRAINT BARRIER

The bottom half of the walkthrough feed barriers are covered in mesh, which is extremely useful at lambing time to stop lambs from going from one pen to another and getting mixed up.At the front of each pen, facing the feeding passageway, is a small gate that allows access into each of the eight large group pens.

SMALL DRINKING FOUTAIN

There are small exit gates in each of the pens leading out to the feed passageway, which makes it handy to move ewes out to the individual pens come lambing time or just to go in and walk through the ewes.Small drinkers – one in each pen – were installed and a drinking system for the individual pens was just nearing completion.

STEPPER SHEEP SLATS

In the middle two slatted tanks, which have a spine-wall, and the remaining tank, plastic slats specially designed for sheep were used.The plastic slats would be a better option for the ewes when they are lambing. They would be a lot warmer than on ordinary concrete ones.The plastic slats have notches in them, so there is plenty of grip on them.

LAMB ADOPTION GATE

This adoption gate clicks into existing lambing pen, this eliminating the backache and stress of moving the Ewe to a separate pen. You can convert a lambing pen into an adoption pen in a matter of seconds, this allows you to utilise space better and saves time. This adoption gate is lightweight so it can be easily moved between pens. Every sheep farm should have one of these!

SHEEP HEAD LOCK

More peace for the animals, by very quiet rung stops. Can be used for young sheep and goats over 12 months,Modular design for every stand width, Legal regulations safely and easily complied with, Fixation possibility against rank fights when eating. Proven locking system, easy group and single outlet

SHEEP BRUSH

Movable brush body is interesting for animals,Firm and stable, Good reach of the entire goat ,Robust quality and hot-dip galvanized,Two brushes provide maximum massage effect,Easy starting by turning the brush,Scratchy pleasure for as long as the animal is under the brushes.

AUTOMATIC FEEDING

Automatic feeding has been tried and tested and makes your everyday life easier. You will noticeably have more time! Multiple, automatic feed template, needs-based quantity, less loss of feed.

MILKING PARLOUR

Milking parlour for sheep and goats with 2 x 24 stands at one milking device, front pressure, dosing of core during milking.

STRAW BEDDING SYSTEM

Is the automatic bedding system for species-appropriate goat and sheep husbandry. Straw bales are dissolved and crushed, in appropriate quantities. Safety technology ensures fire prevention. The straw quality is improved. Sprinkle clean - almost dust-free!

Technical Training

Equipment management application training

Ensure that employees master the knowledge of equipment management, ensure that equipment operates with high efficiency, long cycle, safety and economy.

Breeding management process training

Let employees master pig feeding, management, disease prevention and safety knowledge, etc., so that staff can lay the foundation for future work.

Equipment operation application training

Enable equipment operators to have a comprehensive understanding of the equipment, enhance their skills in maintaining and using the equipment, be fully competent in the work they undertake.

Delivery at Production Capacity

Operation and Maintenance

production process