NaN / 0

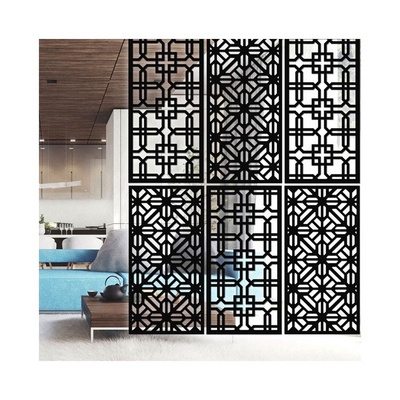

Customized Personalized Laser Cut Aluminum Alloy Privacy Screen Metal Partition Laser Cutting Panels

Get Latest Price

US$ 0.09

≥1 Pieces

US$ 0.07

≥50 Pieces

US$ 0.05

≥100 Pieces

US$ 0.03

≥1000 Pieces

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

tiancheng

Model Number:

TC0008

Product Name:

Stainless steel aluminum laser cutting service

Product Details

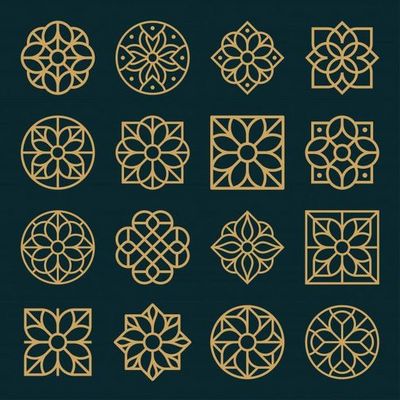

The above prices are for laser-cut metal ring parts, the outer ring diameter is 4cm, and do not include processing. If you need customized styles, please contact us.

Customized Personalized Laser Cut Aluminum Alloy Privacy Screen Metal Partition Laser Cutting Panels

Fine processing Quality assurance

Metal plate laser processing production

We can custom according to your drawing or sample

Sheet metal working

Chassis Cabinet shell processing

CNC bending machining

winding

Laser cutting and welding processing

1. ONE-STOP SHEET METAL/ STAMPING SERVICE

2. CUSTOMIZED FABRICATION SERVICE

3. HIGH QUALITY WITH SGS CERTIFICATION

4. FAST DELIVERY

| Surface Treatment | Aluminum | Stainless Steel | Steel | Plastic | Brass |

| Clear Anodized | Polishing | Zinc plating | Painting | Gold plated | |

| Color Anodized | Passivating | Oxide Black | Chrome Plating | Electroplating | |

| Sandblast Anodized | Sandblasting | Nickel Plating | Polishing | ||

| Chemical Film | Laser Engraving | Chrome Plating | Sandblast | ||

| Brushing | Carburized | Laser Engraving | |||

| Polishing | Heat Treatment | ||||

| Chroming | Powder Coated |

| Material Available | Stainless steel: 201SS, 301SS, 304SS, 316SS, etc. |

| Aluminum: AL6061, AL6063, AL6082, AL7075, AL5052, etc. | |

| Steel: carbon steel, alloy steel, stainless steel, 4140, 20#,45#, 40Cr, 20Cr, etc. | |

| Brass: C37700, C28000, C11000, C36000, etc. | |

| Plastics: PTFE, PEEK, POM, PA, UHMW, NYLON, etc. |

| Application | Bike | Automobile Industry | Computer Equipment | Agricultural Equipment |

| Textile Equipment | Automobile Industry | Measuring Instruments | Medical/Dental Instruments | |

| Safety Equipment | Automobile Industry | Pumps Connections | Pharmaceutical Industry | |

| General Machinery | Pharmaceutical Industry | Fixing Equipment | Industrial Valves | |

| Sanitary Fittings | Instrumentation Equipment | Food Beverage Processing | Orthopedic Implants |

Q1: Are you trading company or manufacturer?

A1: We are factory, so we can provide competitive price for you.

Q2: What kind of service can you provide?

A2: Our company can provide OEM sheet metal fabrication, CNC machining and manufacturing service.

Q3: What's kinds of information you need for a quote?

A3: In order to quote for you earlier, please provide us the following information together with your inquiry. 1) Detailed drawings (STEP, CAD, SOLID Works, PROE, DXF and PDF)

2) Material requirement (SUS, SPCC, SECC, SGCC, Copper, AL, ETC.)

3) Surface treatment (powder coating, sand blasting, planting, polishing, oxidization, brushing, etc.)

4)Quantity (per order/ per month/ annual)

5)Any special demands or requirements, such as packing, labels, delivery, etc.

Q4: What shall we do if we do not have drawings?

A4: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

Q5: What makes you different from others?

A5:1) Our Excellent Service We will submit the quotation in 48 hours if getting detailed information during working days.

2) Our quick manufacturing time For Normal orders. As a factory, we can ensure the delivery time according to the formal contract.

Q6: Is it possible to know how are my products going on without visiting your company?

A6: We will offer a detailed production schedule and send weekly reports with photos or videos which show the machining progress.

Q7: Can I have a trial order or samples only for several pieces?

A7: As the product is customized and need to be produced, we will charge sample cost, but if the sample is not more expensive, we will refund the sample cost after you placed mass orders.

Q8: What's your after-sale service?

A8: If there is quality problem, please provide photos or test report, we will replace defective goods or return funds.

Choose Us

1) Design assistance and full engineering support .

2) Professional at OEM CNC parts .

3) Complete production lines for custom turning, milling, CNC machining sheet metal fabrication, stamping, bending, argon welding

and surface treatment.

4) Advanced machine tools, CAD/CAM programming software.

5) Prototype machining capabilities.

6) Strict quality control standards with a highly qualified inspection department .

7) Continually upgrading and advancing our equipment to remain competitive .

8) Small quality is also available.