1. Control box: Independently developed fourth-generation control box.

2. Mechanical Frame: Stainless steel and brushless motors have been used to make dinosaurs for many years. Each dinosaur’s mechanical frame will be continuously and operationally tested for a minimum of 24 hours before the modelling process begins.

3. Modelling: High density foam ensures the model looks and feels of the highest quality.

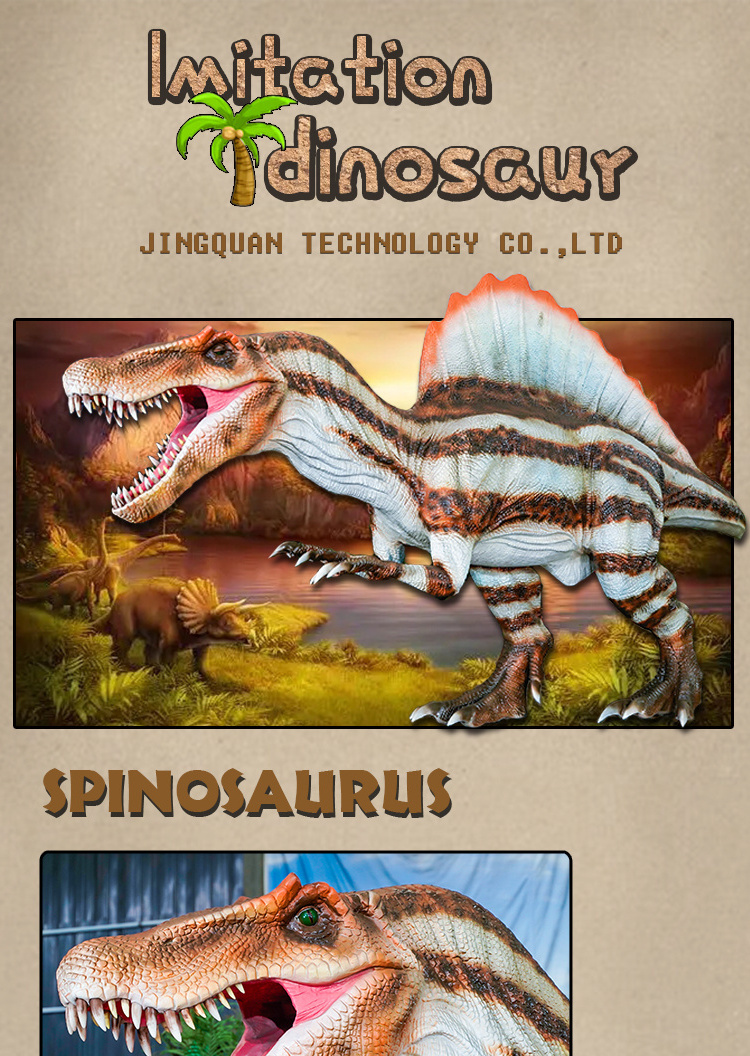

4. Carving: Professional carving masters have more than 10 years of experience. They create the perfect dinosaur body proportions absolutely based on dinosaur skeletons and scientific data. Show your visitors what the Triassic, Jurassic and Cretaceous periods really looked like!

5. Painting: Painting master can paint dinosaurs according to customer's requirement. Please provide any design

6. Final Testing: Each dinosaur will also be continuous operated testing one day before shipping.

7. Packing & Shipping: Bubble bags protect the dinosaurs from any damage from transit. PP film fix the bubble bags. Each dinosaur will be packed carefully and with particular focus on protecting the eyes and mouth.

8. Mechanical Design: We make a mechanical design for every dinosaur, providing them with a good frame. This makes sure that their air flows and other moving parts can operate without friction, massively improving the service life!

9. Dino Posture & Color Design: We design dinosaur postures, detailed features and colors before production begins. This ensures you get exactly what you want.

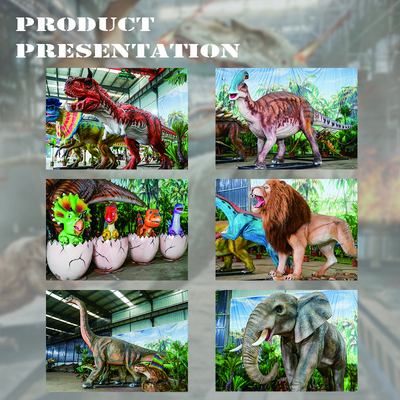

10. Graphic Design: You provide us photos and plans, we get back to you an entire dinosaur exhibition!

11. Exhibition Details Design: Exquisite and detailed designs show you what the final exhibition scene looks like.