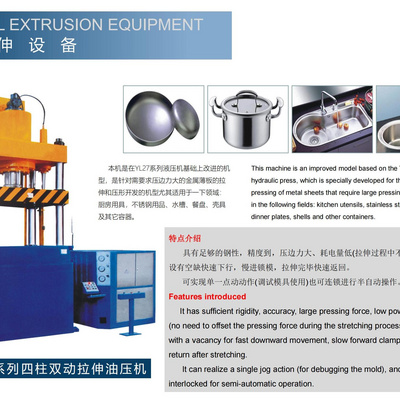

Feature

LT-YL32 series hydraulic press is mainly suitable forvarious stamping or pressing processes such as stretching,bending, flanging, calibration, press-fitting and cold andhot extrusion, blanking and other metal materials, and is also suitable for the pressing and forming process of non-metallic materials such as powder products, abrasive products, composite materials, and insulating materials. According to the molding process of the product, this machine has the working process of fast slider idle stroke,slow clamping and pressurization, pressure holding, pressure relief and fast return, lower cylinder ejection and return.