NaN / 0

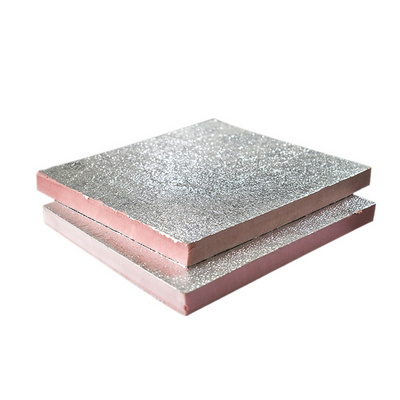

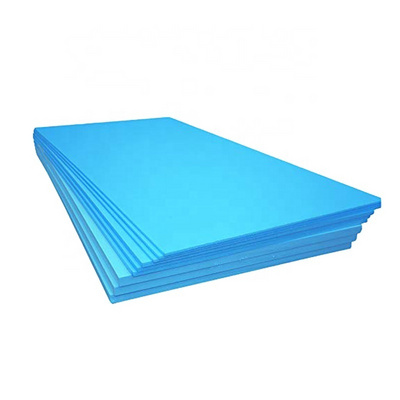

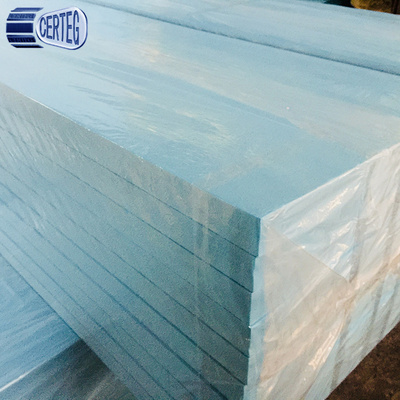

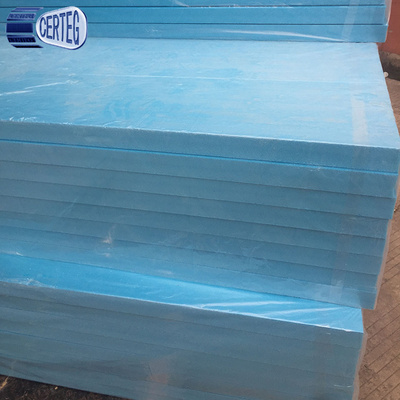

High Density XPS Extruded Polystyrene Foam Board

Get Latest Price

US$ 40

≥1 Cubic meter

Quick Details

Place of Origin:

Zhejiang, China

XPS board width:

600mm ~ 1200mm

XPS board length:

≥1200mm

XPS board thickness:

20-100mm

Product Details

XPS Foam Board

Zhejiang Certeg produce and export heat insulation material XPS Foam Board all over the world. Light weight, time proof, cheap price, XPS foam board has become a popular interior finishing material.

What are XPS Foam boards ?

XPS foam is an insulation board manufactured of fully recyclable material. It is produced from foamed polystyrene, a material that doe’s not deteriorate. The cell structure in the board is built up of very fine closed cells that give the product its excellent physical and mechanical characteristics.

An excellent insulation that saves energy

This special cell structure means that the sheet does not conduct heat. When you lay XPS boards as an underlay any heat from your room or floor will be reflected back towards the floor surface. As you will not be wasting heat through your floor you will utilize your energy in an effective manner and thereby lower your energy consumption and carbon footprint.

Effective protection against cold and damp

XPS boards not only take care of the heat, they are also an effective guard against the cold and damp. The cold will be held back by the non conducting characteristics of the foam and as XPS board is also water repellent it will not rot or go mouldy and will help hold back any damp from your floor.

XPS boards are also resistant to cement, plaster, and most alkalis, however not against organic solvents.

Sound insulation

In addition the boards have an excellent sound insulating effect, which makes the floor “ quieter ” to walk on and an ideal product for use when you need to reduce sound transmission to the room below.

1. XPS Foam Board Main Parameter :

|

Material |

Poly styrene |

|

Production precess |

Thermo extrusion |

|

Board width |

600~1200mm |

|

Board length |

>1200mm |

|

Board thickness |

10~120mm |

|

Surface Treatment |

1. Smooth(with skin) 2. Roughening(without skin) 3. Line groove surface 4. Special embossing surface |

|

Color |

white/blue/pink/yellow etc |

|

Density |

28~45kg/m 3 |

|

Compression strength |

150kPa~550kPa |

|

Water absorption V/V |

~0.20% |

|

Moisture permeance |

~0.75ng/m.s.Pa |

|

Size stability L/W/T |

0.28%/0.15%.0.85% |

|

Burning performance |

B1,B2 |

|

Delivery time |

5 -10 days |

2. XPS Production Machine and workshop

3. Warehouse and Storage

4. Application

XPS Board is ideal for applications in the construction industry as it is equipped for 'site survival' and can be cut to shapes that make it extremely fit for use. It also means that XPS Board is ideal for a vast range of fabrication applications where the strength of the material as an infill in panels etc. is widely recognised and valued.

After Service

24 hours feedback, 48 hours solution.

For more information, please kindly contact.

Hot Searches