NaN / 0

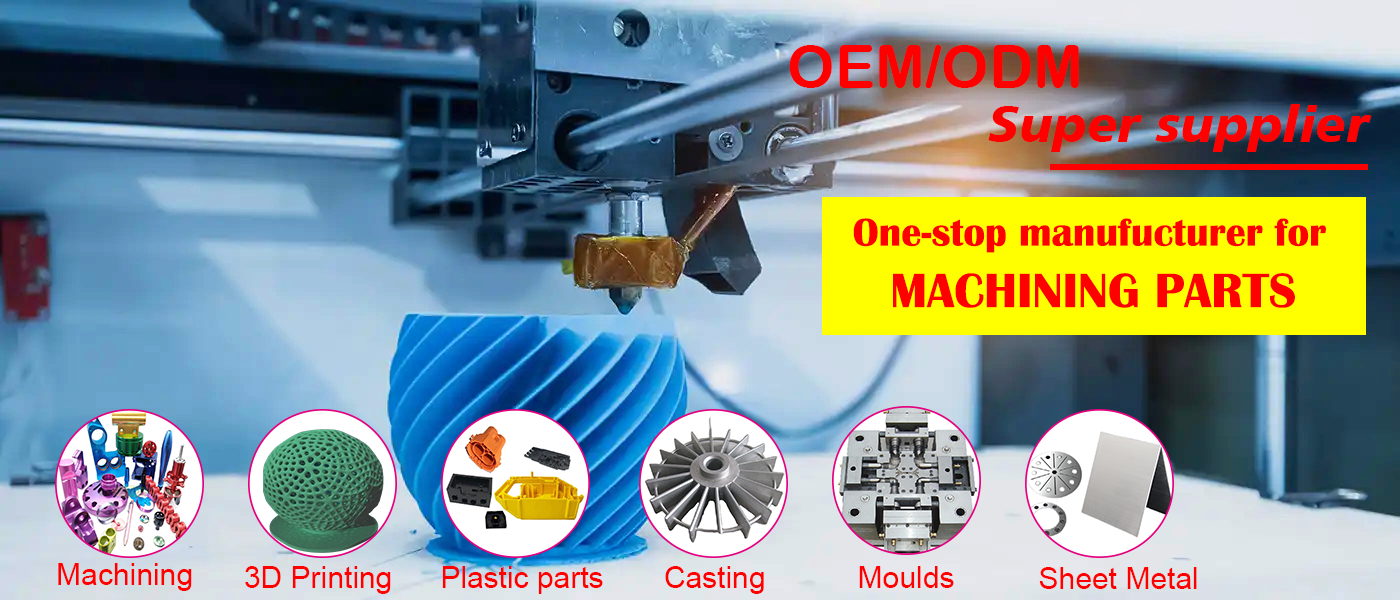

Industrial parts 3D Printing machine service Rapid prototype Polycarbonate rapid prototype 3D printing rapid prototype

Get Latest Price

US$ 1

≥1 Pieces

Quick Details

CNC Machining or Not:

Cnc Machining

Material Capabilities:

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, Plastic

Place of Origin:

China

Model Number:

HZA-0196895

Product Details

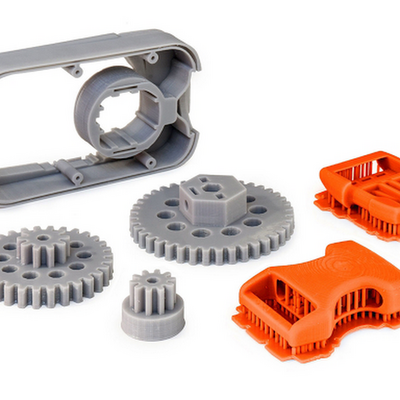

SLA 3D Printing Advantages:

*

High machining accuracy, can reach 0.1mm;

*

Can manufacture complex shape (such as hollow parts), especially fine (such as jewelry, crafts, etc.) parts, suitable for mobile phone, radio, walkie-talkie, mouse and other fine parts and toys and high-tech electronic industrial case, home appliance shell or model, motorcycle, auto parts or model, medical equipment, etc.;

*, fast manufacturing parts, 0.1-0.15mm layer scanning;

* Good surface quality, can make very fine details of thin structure, easy post-processing;

* Processing in place, many CNC manual processing of the details can be processed out, thus reducing the workload of post-processing;

SLA technical principle:

|

Mold Material

|

Aluminum,45#, P20, H13, 718, 1.2344, 1.2738 and so on

|

|

silicon rubber Material

|

NR, NBR, SBR, EPDM, IIR, CR, SILICONE, VITON,etc

|

|

Plastic Material

|

PC/ABS, ABS, PC, PVC, PA66, POM or other you want

|

|

Plastic Surface finish

|

Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc

|

|

Drawing format

|

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc..

|

|

Certificated

|

ISO 9001:2015,SGS

|

Product Description

3D Printing FDA

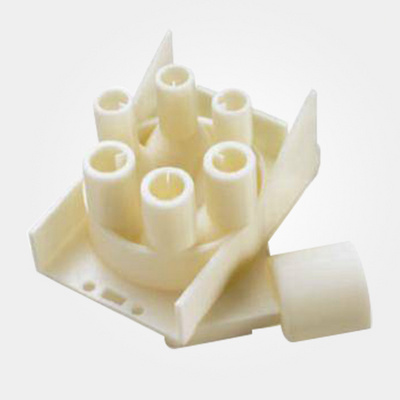

Fused Deposition Modeling (FDM) rapid prototyping process is a method of heating fused silk materials (e.g. engineering plastic ABS, PC polycarbonate, etc.) which does not rely on laser for forming energy source

3D Printing 3DP

It's called BinderJetting, Inkjet Powder Printing. Three-dimensional printing and traditional two-dimensional inkjet printing is closest to the SLS process. 3DP is also made by unbonded powder into a whole. The difference is that it is sprayed by the binder.

3D Printing LPD

Digital Light Processing, a technology first developed by Texas Instruments, uses projectors to solidifies light-sensitive polymer liquids layer by layer to create 3D printed objects.

3D Printing SLA

Photocuring: UV curing resin is used as raw material, resin is poured into the fat tank and immersed into the printing platform; Use UV laser or DLP projector to shine UV light on the resin. The printing range of each layer of horizontal section is hardened and raised from the container by the platform to continuously stack

.

3D Printing SLS

Laser sintering: Using a powder polymer, the powder is stored in a container. A thin layer of powder is laid out within the printing range. A laser light fusion material is used to create a single horizontal layer

3D Printing SLM

The metal powder is completely melted by high energy laser beam under the action of heat, and then formed by cooling and solidification. SLM equipment can be divided into down feed powder and up feed powder according to different feeding methods.