The production flow is as follows:

1. The user collate the empty bottle on the turntable,

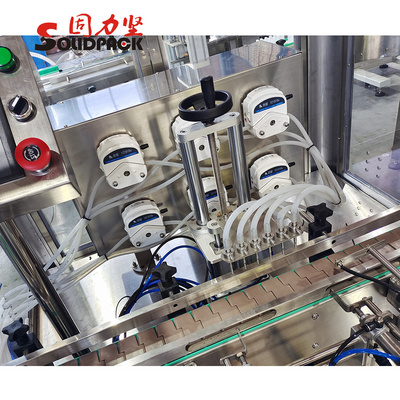

2. Then bottle will be put into the mould automatically, next step the mold be push into the next position by the cylinder controlled by PLC, the nail polish is delivered to the head of the pump by the sealed pressurized storage tank, and the material is poured into the bottle through the filling nozzle.

3. After filling station, the bead is put into the bottle. Then the brush is delivered by the vibrating machine and be put into the bottle by the brush mechanism.

4. The next workstation, vibration machine delivers the cap and cap be placed on the bottle mouth. After the cap is tighten by the capping head, bottle will be clipped out of the mold and be put on the conveyor belt.

On this machine, we will add cosmetic powder filling machine, cap unscrambler, sealing machine.

Note : A capping machine can cap powder lids and nail polish caps. Just change some parts.

On this machine, we will add cosmetic powder filling machine, cap unscrambler, sealing machine.

Note : A capping machine can cap powder lids and nail polish caps. Just change some parts.