NaN / 0

New saving energy low price zhongzhou briquette press machine

Get Latest Price

US$ 1000

≥1 Sets

Quick Details

Place of Origin:

Henan, China

Product name:

Briquette press machine

pressure stype:

Wedge papilionaceous spring stype

Structural form:

Two rollers and single pressure/Four rollers double pressure

Product Details

New saving energy low price zhongzhou briquette press machine

Product Description

Briquette press machine introduction:

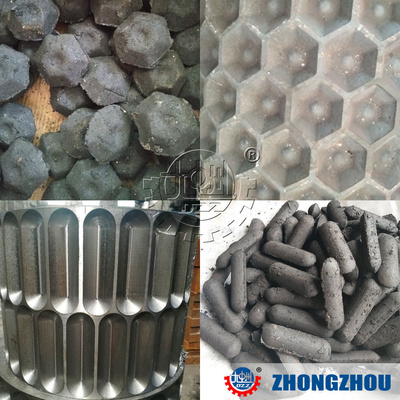

Zhongzhou versatility of briquette press machine is coal forming process equipment, which provide corresponding pattern die, can process oval, oblate, pillowed, squared (in 30~60mm) coal. This machine is suitable for working in single or in large flow making coal line, is also can be used in liquidity work.

This zhongzhou briquette press machine can choose different raw materials for two parts to make product's fluctuation. Adopting two-step forming method, increases combustion time, improve combustion calorific value; and also it can manufacture various special different molds.

Products Application

Briquette press machine usage and features:

1. In order to ensure the good quality and mechanical strength of the final product, special care should be taken to ensure that the granule size fed to the zhongzhou briquette press machine is maintained below 3mm, preferable in the range of 30-40% small than 1-2 mm, with no more than 10% over 2mm.

2. The moisture content of the mixture has also a critical effect on the quality of the final product, so it should be kept in the range of 8-20%.

3. Raw material of coal industry ( coal powder, coke, coal sludge, etc)need to make coal briquette, using in industrial boilers and civilian boiler.

Production Line

1. Briquette making machinery: machine, belt conveyor, feeding machinery, drying machine, mineral briquette machine, etc

2. Rotary Drying Plant: Sand and Gravel Production Line, Powder Rotary Drying Plant, Rotary Kiln, cement production line, etc.

3. Mining machinery: Crusher, ball mill, flotation machine, etc.

Products Structures

Briquette press machine features:

---The roller is made by hard materials, with good wear resistance and long life time;

---The service life of wearing parts is up to 4000 hours;

---The machines electricity cost reduces by 60%;

---The machine is easy to operate and maintain;

---The molding material is energy-saving, easy to transport and higher utilization of waste.

---The final product is smokeless, non-toxic, none peculiar and environmental protection.

---The end products shapes include oval, round, square, ball egg-shaped and pillow-shaped.

Products Principle

Working principle of briquette press machine:

This series of briquette press machine will make the powder pass the power on to the two pressure roller through the reducer. The two sides and roll rotation, in both the rotating roll. Natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger. When the material to the two rollers rotating line contact point, the pressure of materials has reached the peak. Tremendous pressure in the role of line, the materials become a finished product from the powder ball.

Technical Parameter

Technical parameters of briquette press machine:

Product Benefits

Dear friends: our briquette press machine will adopt wear-resistant alloy roller (patent technology) from March, 2007. This is because the roller is not wear-resistant, So our company use special casting technology with nice material, making roller’s life longer and increase 5 times life-span. Of course, the new roller can save operation cost, reduce production investment,less maintains, this best choice for you to choose our machine.

Any question pls contact me. It is our goal to offer the best service to you.

Hot Searches