NaN / 0

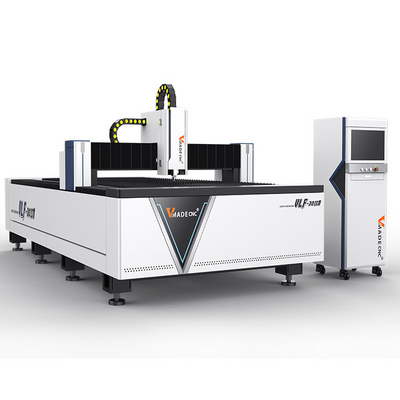

1000w 2000w 3000w Fiber laser cutting machine high accuracy stainless steel carbon steel iron laser cutting machine

Get Latest Price

US$ 16800

≥1 Sets

US$ 10000

≥10 Sets

Quick Details

Laser Type:

Fiber Laser

Cutting Speed:

15m/min

Cooling Mode:

WATER COOLING

Control System Brand:

Cypcut

Product Details

Product Description

1000w 2000w 3000w Fiber laser cutting machine high accuracy stainless steel carbon steel iron laser cutting machine

The applicable materials include: ordinary carbon steel, stainless steel, Alloy steel, Aluminum, copper, titanium plate etc.

S uitable for aerospace technology ,rocket, plane, robot, elevator, steamship and automobile manufacturing and metal parts processing industry for metal plate, advertisement, kitchen ware, bit tool, hardware etc.

1.Integrated machine design, left and right collecting drawer design highly saving space.

2. Stability and reliability for light path system and control system.

3. Fiber laser has high and stable function and lifespan which is over 100000 hours.

4.Higher cutting quality and efficiency with cutting speed being up to 1 5m/min with perfect cutting edge.

5. High performance reducer, gear and rack; Japanese servo drivers and more effective in cutting.

6. Imported ball screw and square guide provides high speed and accuracy when working.

7. Water chiller high capacity provides stability during long-term operation.

8.A separate control box and handheld control makes it easier to control the machine.

10. Without consumables. Easier to use, adjustment of the optical beam is not necessary.

|

Model |

CA-F1530 |

|

Working area |

30 00x 15 00mm |

|

Laser Power |

10 00W |

|

Laser Wavelength |

10 64 nm |

|

Application Materials |

Metal |

|

Max. Cutting Thickness |

CS:0-8mm,SS:0-4mm |

|

Gross Power |

9 KW |

|

Positioning Accuracy |

±0.03mm/m |

|

Reposition Accuracy |

±0.02mm |

|

X/Y-axis Maximum Simultaneous Positioning Speed |

140m/min |

|

Cutting speed |

8 0m/min |

|

Cooling Model |

Water cooling |

|

Rotary system |

Optional |

Product Description

Original cypcut controller

Original CypCut control system with computer display screen and remote controller.Able to completed the whole process from design,process design to processing,simple,efficient,powerful and reliable!

Auto -Focus Laser Cutting Head

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position within 20mm. The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials. The compound lens group equipped with D28 integrates the light beam and optimizes the optical and water-cooled design so that the laser head can work stably for a long time.

Laser source

Customer can chose suitable laser source according to actual needs.

Brand :IPG,Raycus,MAX,Reci

Power: 1000w,2000w,3000w,4000w

Welding bed

High tensile strength, sturdiness and durability, the weld will not break; it can be used continuously for more than 20 years

CWFL water chiller THK guide rail

Packaging & Shipping

Package & Delivery:

Step1: water proof wrapping film with foam protection in each corner.

Step2: Solid seaworthy wood box package with steel belt.

Step3: Save space as much as possible for container loading.

Our Services

Service& Support:

CAMEL CNC provides three types of After-Sales service:Hot-line support,Email-support,and On-Site Machine installation.You could choose any type for your convenience details as below:

1 After receiving machine clients could install in guide of video and instructions provided.

2 lf you have any question during installation or operation,we will assist via Skype.Whatsapp.Teamviewer or other tools online until clients can operate machine skilfully.

3 If client needs,we could provide sample drawings for testing.

4 lf clients need on-site installation and training we will charge $200per day as well as round train costs for sending technician and local Accommodation or you could contact your sales manager for discussing details.

5 Our company will contact clients on machine working status feedback new requirements or good suggestions regularly and revert back to our company functional departments to improve our machines or service.

Hot Searches