NaN / 0

Palm/soybean/sunflower/rice bran/cottonseeds/corn oil refining plant

Get Latest Price

US$ 13500

≥1 Sets

US$ 13000

≥10 Sets

Quick Details

Production Capacity:

100%

Place of Origin:

Henan, China

Brand Name:

HUATAI

Voltage:

220v/380V

Product Details

Henan Huatai Cereals And Oils Machinery

Focus on development and manfacturing of various types of grain and oil machinery, providing solutions and related products, has won high praise by customers from many countries around the world.

To build brand by quality,

service to enhance the credbility.

Main Projects Scope

30-5000T/D oilseeds pretreatment project

30-5000T/D oilseeds extraction project

10-500T/D crude oil refining project

10-500T/D crude oil fractionation project

Oil interesterification project

Oilseeds protein, phospholipid project

Natural pigment extraction project

Grain deep processing project

Palm/soybean/sunflower/rice bran/cottonseeds/corn oil refining plant

Sunflower oil is the most widely used oil due to its high linoleic content which is considered nutritionally positive. The kernel accounts for 70% of the seed and the oil content is about 40%-45% in the seeds.

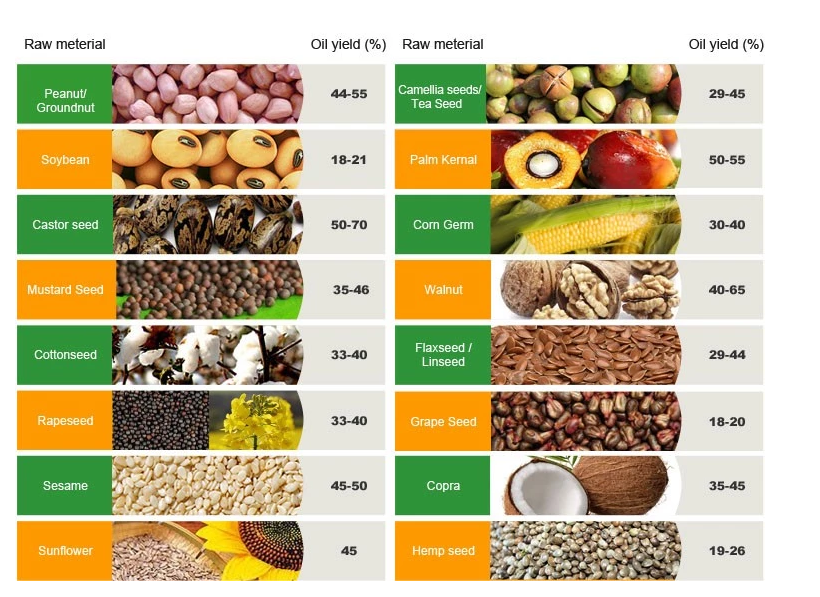

Sunflower oil making machine can process all kinds of oilseeds ,such as palm kernel , rapeseed ,

rice bran , cotton seed , soybean ,peanut and sesame seed , nuts ,fruit which has certain oil.It is a complete process.Generally speaking ,it has three steps :

(1)Sunflower seed pre-treatment workshop.

(2) Sunflower oil solvent extraction machine.

(3)Crude sunflower oil refining machine.

OIL PRESSING MACHINE

1. Sunflower seed pretreatment machine

Crude material → cleaning → softening → prepressing → drying → to extraction workshop

Pretreatment and prepressing section is a very important section before extraction.It will directly affect extraction effect.

CHARACTERISTICS

1.

Healthy! Physical squeezing craft maximally keeps the nutrients such as the protein, fatty acids and minerals, etc.

2.

High working efficiency! The spiral squeezing structure can achieve high oil output, thus the oil content of the residue cake is low.

3.

Long durability! All the parts are made of the most suitable material and treated with refined crafts to ensure the long term runing, such as cemented quenching and tempering to increase the hardness, consequently the durability.

4.

Cost-effective! The wearing parts on the machine such as the squeeze loop, squeeze spiral and squeeze bar are designed to be dismountable. When they are out of service period, users only need to replace them and no need to displace the whole machine.

2. Sunflower oil extraction machine

(1)continuous alkali refining shortens contact tome between oil and lye,which reduces oil saponification state,lowers refining consumption,and improves efficiency;

OIL REFINERY MACHINE

Huatai has the ability to build a complete set of multiple oilseeds oil refinery production line, we can provide you with turnkey project.

Our oil refienery line can process multiple oilseeds, scuh as soybean, corn germ, peanut, cottonseed, sunflower, sesame and so on.

(2)decolorization craft adopts technology of combining premixing and steam mixing bleaching,which improves bleaching efficiency,saves consumption of bleaching clay, and it is simple and convenient to operate ; besides,negative pressure state avoids oxygen in the air from contacting with hot oil,thereby ensuring oil product quality ,inhibiting with hot oil,thereby ensuring oil product quality,inhibiting acid value to rise again,and lowering peroxide value;

CHARACTERISTICS

1. Continuous alkali refining shorten the contact time of oil and lye, reduce fat saponification, low power consumption and improve efficiency;

2. Bleaching and steam stirring decolorization premixed combination of technology, improve the decolorization efficiency, saving the amount of clay, simple operation; a negative pressure and oxygen in the air to avoid contact with hot oil, to ensure the quality of oil, acid value rise suppression, reduce excessive oxidation number.

3. Using the new continuous physical refining deacidification deodorization, deacidification deodorizing suitable for high acid value and low gum content of the vegetable oil, the actual production proves that the process has the following salient features: strong acid removal ability, good heat decolorization, refining rate, good quality oil.

4. The process multiple heat exchange systems take advantage of the heat, reduce steam consumption, the production process also has an adjustable, flexible operation, high automatic degree of sanitation.

Applicable oil: soybean oil, sunflower oil, rapeseed oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil, animal oil all need refining oil.

(3)physical refining section adopts new type continuous deacidiffication and deodorization craft,which is applicable for vegetable oil of high acid value and low resin content,the actual production proves its most obvious advantages as following: strong deacidiffication ability ,excellent hot bleaching effect,high refining rate ,good oil quality etc.

Henan Huatai can provide you with 10 to 25 kilograms (test equipment), 2 to 1,000 tons / day of oil refining projects , Henan Huatai naturally is your preferred partner for different oil quality. in Henan Huatai here are different options, batch chemical refining, semi-continuous physical refining, continuous physical refining program, where Henan Huatai provide you with the design (process, civil, electrical), manufacturing, installation, commissioning, training of technical personnel to the sale a full-service; advanced automatic control system to ensure that the entire production line of automatic, smooth operation; heat saving each segment to ensure that the processing costs to a minimum.

MAIN REFINING PLANT PROCESSES

Degumming, dehydration, bleaching, deacidification, deodorization, dewaxing, degreasing. Crude oil in squeeze, extraction crude oil

can be obtained national quality standards of edible oil through refining plant .

.

CASE

--- 100TPD tea seed oil refinery and dewaxing plant

100TPD tea seed oil refinery and dewaxing plant produced by Henan Huatai Cereals and Oils Machinery Co.,Ltd.The equipment is of our own manufacture.

Our company has developed projects including oilseed pretreatment and pressing, oil extraction, oil refining production line ,etc.

DELIVERY & INSTALLATION

After-sales Service

1.Highly inspecting equipments in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipments;

4.Dispatching engineers to install and debug equipments;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems;

7.Providing life-long maintenance service;

8.Providing technical exchanging;

TECHNICAL SUPPORT

1.Our factory is located in Huaxian County,our factory covers an area of 100000m2, with 8 standard processing workshops, 202 sets of machining equipment, 580 staff, 12 intallation teams.

2.Our trademark "Hangpeng" win TOP 10 oil machine brand, because of excellent product quality and perfect after-sale service.

3.We have successfully obtained 29 national patents (including 9 invention patents), 6 international awards, 4 national awards and 2 provincial awards.

4.We have the most complete production certificates of oil machines, such as "Design license of pressure vessel","Manufacture license of pressure vessel","Design license of pressure pipeline","Installation,reconstruction and maintenance license of pressure pipeline", "Manufacture license of organic heat carrier furnace" and installation certification of mechanical and electrical equipment".

5. We are outstanding member enterprise of CCOA (Chinese Cereals and Oils Association), so we produce machines according to standard, and refined oil reaches the best edible oil standard.

6.We have strong R & D team, production team and installation team, offer perfect after-sale service, after delivering goods, we will dispatch technicians to instruct installation, commissioning and train your workers to operate machines by yourselves.

7.We are provincial enterprise abiding by contracts and keeping promises, we have produced oil machines for 65 years, with rich experience and own brand, so we are responsible for all of our projects, especially for oversea projects.

8.Overseas projects: we are establishing every perfect overseas sample project all over the world, such as Estonia, Russia,Ukraine Kazakhstan,Uzbekistan,Tajikistan, Indonesia, Thailand, Bangladesh, Myanmar,Cambodia,the Philippines,Egypt,Ethiopia, Kenya,Tanzania, Rwanda, Congo, Cameroon,Nigeria, Bolivia,Peru,etc.

9. Our equipment guarantee period is 2 years.

Hot Searches