NaN / 0

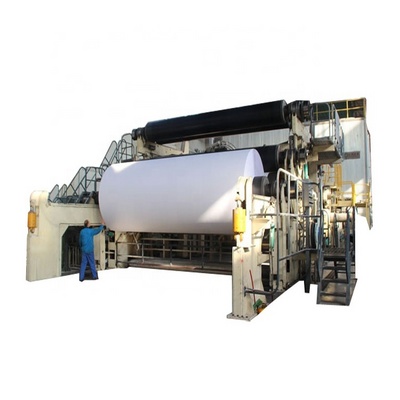

New tissue paper making machine, high quality fully automatic tissue paper machine/toilet paper machine manufacturer

Get Latest Price

US$ 7000

≥1 Sets

US$ 6000

≥5 Sets

US$ 5000

≥10 Sets

US$ 4000

≥20 Sets

Quick Details

Production Capacity:

1200piece/min

Place of Origin:

China

Brand Name:

MING YUAN

Voltage:

380V

Product Details

Customized content

We can make napkins according to your needs

Choose paper size and color

We can make corresponding finished products according to the finished product size you need

Choose the number of paper

How much quantity can we split each according to your request

Choose the packaging method

Different packaging styles can be requested according to your preferences

Products Description

|

Product Type

|

High speed paper napkin machine

|

|

|

|

||||

|

Machine Model

|

MY-CJ270

|

|

MY-CJ330

|

|

||||

|

Speed

|

1200pcs/min

|

|

|

|

||||

|

Power Supply

|

380V,three-phases

|

|

|

|

||||

|

Finished Product Size

|

Open size 270*270 mm

|

|

Open size 330*330 mm

|

|

||||

|

Layers OfThe Paper

|

2-3 layers 15 -18 g/ m²

|

|

|

|

||||

|

Raw MaterialsMaximum Width

|

300mm

|

|

340mm

|

|

||||

|

Material Diameter

|

1200mm

|

|

|

|

||||

|

Inner Diameter ofRaw Paper Core

|

Φ76.2mm

|

|

|

|

||||

|

Embossing

|

One set steel to paper

|

|

|

|

||||

|

Folding Type

|

1/4

|

|

|

|

||||

|

Power Consumption

|

5KW (The host power: 2.2kW Cutter power: 0.55 KW)

|

|

|

|

||||

|

Broken PaperFeatures

|

Embossed cut paper stop position

|

|

|

|

||||

|

Printing Color

|

1 or 2 color(optional device)

|

|

|

|

||||

|

Counting

|

Electronic counter,pneumatic hop

|

|

|

|

||||

|

Weight

|

800KGS

|

|

1100KGS

|

|

||||

|

Machine Dimension

|

1.9x1.3x1.12M175x1.17x1.6M(two packages)

|

|

|

|

||||

|

OEM ( Show Client Company Name in Machine Panel ) is welcome in our factory

|

|

|

|

|

||||

Machine introduction

If you want to know about our production line

Automatic napkin machine production line

This efficient production line consists of three machines: an automatic napkin paper folding and cutting machine, a paper napkin stacking machine, and an automatic napkin packaging machine. With minimal labor requirements, this production line automates the entire process from folding and cutting to quantity distribution and packaging. Increase productivity, reduce costs, and deliver high-quality napkins to meet customer demands. Upgrade your production line today and stay ahead!

Selling point of a product

Control Panel

Simple and easy to operate, equipped with better quality switches and button , All the operation can be finished and controlled in this panel.

Electric System

Electrical System with high-quality brand electrical components stable and better quality.

Pattern Embossing Unit

It is adopted with steel to wool roller,pattern of the napkin can be made according to the needs of users.Embossing pattern is clear and will not loose layer

Cutter Unit

Durable bandsaw cutter unit can cut the napkin faster.longer service life

Color Printing Device

Adopts flexible printing,the design can be customized design as your requirement, using professional color priting anilox and string ink rollers which can the water ink equally spread , the printing logo is clear and bright.

Company strength

Recommend Products

FAQ

Q1. Are you trading company or manufacturer?

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is

feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is

feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

Hot Searches