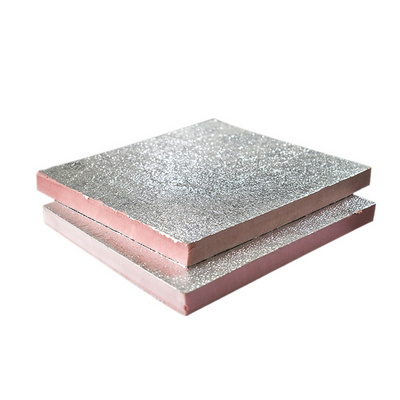

Feature

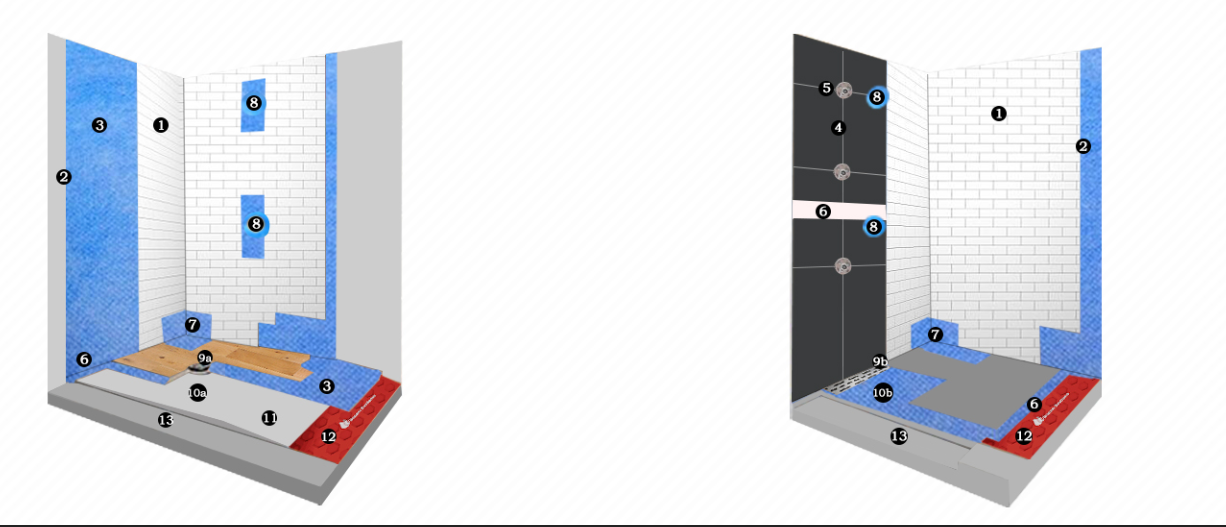

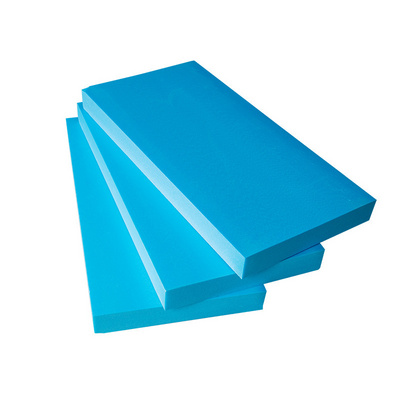

1. 100% waterproof, made of HCFC-FREE XPS foam

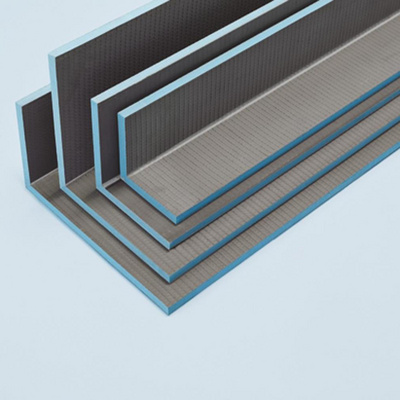

2. High-rigidity and durability

3. Close bond to any tiling walls or floors

4. Available at various thickness and sizes

5. Compatibility to multiple substructures

6. Vapor retardant against mildew

7. Light-weight, easy to handle and cut with utility knife