NaN / 0

Nickel titanium alloy super elastic and shape memory nitinol wire ASTM F2063 for medical price per kg

Get Latest Price

US$ 80

≥1 Kilograms

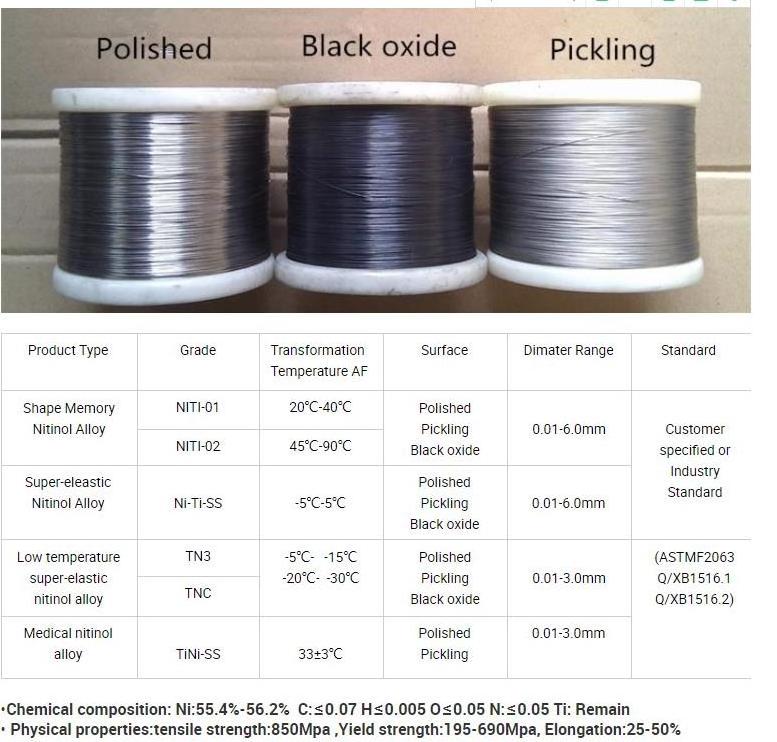

Quick Details

Resistance (μΩ.m):

0.000082 Ω/cm

Powder Or Not:

Not Powder

Ultimate Strength (≥ MPa):

850

Elongation (≥ %):

25-50

Product Details

Nitinol wire

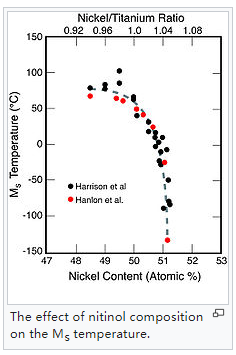

Nitinol is typically composed of approximately 50 to 51% nickel by atomic percent (55 to 56% weight percent). Making small changes in the composition can change the transition temperature of the alloy significantly. Transformation temperatures in nitinol can be controlled to some extent, where A f temperature ranges from about −20 °C to +110 °C. Thus, it is common practice to refer to a nitinol formulation as "superelastic" or "austenitic" if A f is lower than a reference temperature, while as "shape memory" or "martensitic" if higher. The reference temperature is usually defined as the room temperature or the human body temperature (37 °C; 98 °F).

The scenario described above (cooling austenite to form martensite, deforming the martensite, then heating to revert to austenite, thus returning the original, undeformed shape) is known as the thermal shape memory effect. To fix the original "parent shape," the alloy must be held in position and heated to about 500 °C (932 °F). This process is usually called shape setting . A second effect, called superelasticity or pseudoelasticity, is also observed in nitinol. This effect is the direct result of the fact that martensite can be formed by applying a stress as well as by cooling. Thus in a certain temperature range, one can apply a stress to austenite, causing martensite to form while at the same time changing shape. In this case, as soon as the stress is removed, the nitinol will spontaneously return to its original shape. In this mode of use, nitinol behaves like a super spring, possessing an elastic range 10–30 times greater than that of a normal spring material. There are, however, constraints: the effect is only observed about 273-313 K (0-40 °C; 32-104 °F) above the A f temperature. This upper limit is referred to as M d , which corresponds to the highest temperature in which it is still possible to stress-induce the formation of martensite. Below M d , martensite formation under load allows superelasticity due to twinning. Above M d , since martensite is no longer formed, the only response to stress is slip of the austenitic microstructure, and thus permanent deformation.

A nitinol paperclip bent and recovered after being placed in hot water.

Nitinol is deformed at a low temperature, and heated to recover its original shape through the Shape Memory effect.

Detailed image

Bright polished surface

Bright polished surface

Black surface