NaN / 0

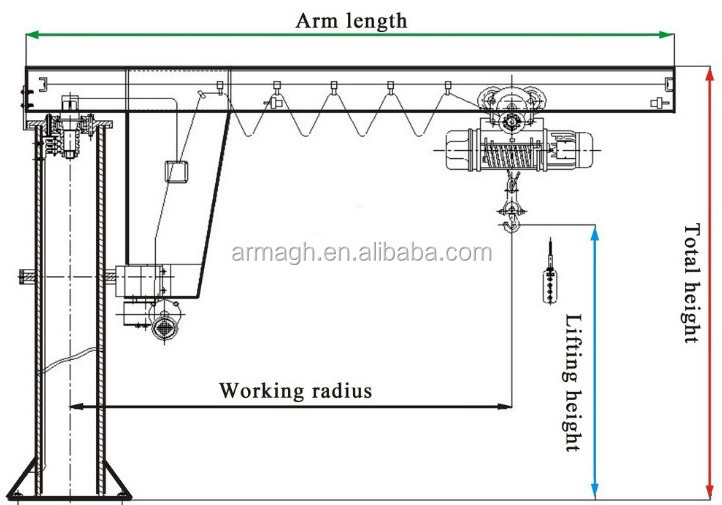

5 ton jib crane design calculation column jib crane jib arm crane

Get Latest Price

US$ 1297

≥1 Sets

Quick Details

Application:

industrial production line

Rated Loading Capacity:

3ton 5ton

Rated Lifting Moment:

50kn

Max. Lifting Height:

10m

Product Details

Product Description

The working strength of cantilever crane is light. The crane is composed of a vertical column, a rotary arm driving device and an electric hoist. The lower end of the vertical column is fixed on the concrete foundation through a foot bolt, and the cantilever is driven by a cycloid pinwheel decelerating device. The electric hoist runs in a straight line from left to right on the cantilever I-beam and lifts heavy objects. The crane boom is hollow steel structure, light weight, large span, large lifting weight, economic and durable. The built-in walking mechanism adopts special engineering plastic wheel with rolling bearings, which has small friction force and light walking speed, and small structure size, which is especially conducive to improving the trip of the hook.

Product Specification

A column type cantilever crane is a cantilever crane composed of a column and a cantilever. The cantilever can rotate around the fixed column fixed on the base, or the cantilever can be rigidly connected to the rotating column and rotate relative to the vertical centerline.Base support.It is suitable for occasions where the lifting weight is small and the service range is round or sector.It is usually used to load and process workpieces such as machine tools.Most cylindrical cantilever cranes use chain electric hoist as the lifting mechanism and operating mechanism, and rarely use wire rope electric hoist and hand hoist.Manual operation is usually used for rotation and horizontal movement, while electric operation is only used when the lifting weight is large.

Wall cranes are cantilever cranes that are fixed to the wall, or can run along walls or other elevated rail support structures.Wall-mounted cranes are used in workshops or warehouses with large spans and high building heights.It is most suitable when the crane is frequently operated near the wall.Wall-row cranes are usually used in combination with the upper beam or bridge cranes to provide a rectangular parallelepiped space near the wall and are responsible for lifting lightweight items. Large items are borne by beam or bridge cranes.

Packing

1.Electricals, electric hoist and parts packed by high quality plywood crate to cut and avoid loss caused by shake and collision during sea transportation.

2. Beams packed by strong plastic woven cloth to protect from rusting in harsh environment of high

humidity.

Qualification Certificate

About us

Henan Hengtai lifting equipment Co., Ltd. is located in the Changyuan lifting industrial

park in Henan province. It is one of the large-scale domestic electromagnetic Equipment Manufacturing Company in China, which integrates scientific research and development, engineering design, production and commissioning, and Henan hi-tech enterprise. Its products are widely used in metallurgy, electric power, coal, mine, building materials, cement, refractory, lifting transportation and other industries, and exported to Southeast Asia, South Africa, the Middle East and other countries and regions.