NaN / 0

yogurt processing line yogurt making machine industrial

Get Latest Price

US$ 20000

≥1 Sets

Quick Details

Place of Origin:

Henan, China

After-sales Service Provided:

Online support

Product name:

Yogurt Processing Line Plant

Raw material:

goat milk, horse milk, yak milk, yogurt, and fresh milk

Product Details

yogurt processing line yogurt making machine industrial

Product Description

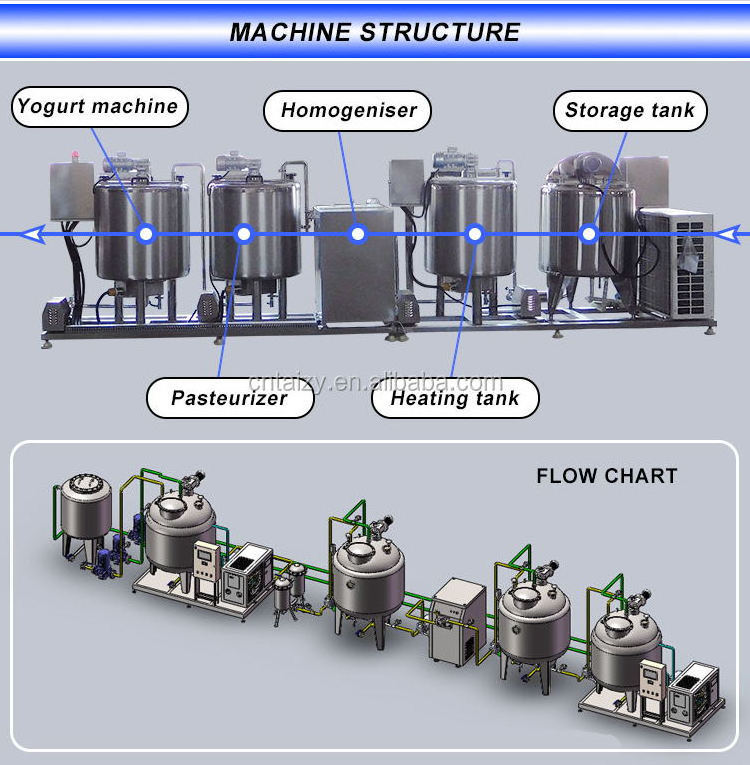

Introduction of yogurt production line

Yogurt production line: The process uses fresh milk as raw material,

which is by

pasteurized and then added beneficial bacteria (fermenting agent) to the milk. After fermentation, it is cooled and filled with a milk product. At present, most of the yogurt products on the market are solidified, stirred, and added with various fruit juice jams and other fruit flavors. Yogurt, due to the fermentation of lactic acid bacteria, improves the nutrient content, and also plays a role in the probiotics of lactic acid bacteria. Yogurt not only retains all the advantages of

milk,

but also some aspects of the processing process is also

healthy food

.

The characteristics of the yogurt production line:

1. Optimize the process, reduce hardware costs and improve performance.

2. High degree of automation, less random factors, and improved work efficiency.

3. The number of personnel is reduced and the labor intensity is allocated reasonably.

4. The layout is simple and beautiful, the logistics channel is smooth, and the floor space is small.

Parameters of yogurt production line

|

Item |

Size(mm) |

Power |

Voltage |

|

1. Storage Tank |

1700*900*1550 |

2.6kw |

380v 50hz |

|

2. Milk Heating Tank |

1200*1000*1650 |

18kw |

380V/50hz |

|

3. Homogeniser |

1010*616*975 |

4kw |

380v 50hz |

|

4. Pasteurizer |

1200*1000*1650 |

18kw |

380v 50hz |

|

5. Yogurt machine |

1200*1000*1650 |

18kw |

380v 50hz |

|

5. Filling machine |

1300*1300*1750 |

/ |

/ |

1. S torage tank

The customer stores the whole milk in the original milk tank and uses the special stainless steel milk pump to pump the raw milk into the pasteurization tank for preheating. If the original milk volume is relatively large, the raw milk can be directly poured into the preheating tank.

2. Milk Heat ing Tank

After the milk is warmed up, the preheated milk needs to be pumped into the homogenized tank through the stainless steel milk pump.

3. Homogenis er

In a homogenized tank, the milk is continuously squeezed to mix the water and milk to increase the taste of the milk.

4. Pasteurizer

The pasteurizer will also be stirred during the heating process. The stirring function is mainly to prevent the milk from appearing on the milk skin. At the same time, the milk is stirred during the sterilization process, and the milk is made to have a better mouthfeel and is more easily absorbed by the human body.

5. Yogurt machine

After the milk sterilization is completed, the fresh milk is pumped into the pre-cooling tank or the refrigerating tank through the milk pump, and then directly fermented in the fermenting tank. The temperature set in the fermenter is about 43 ° C and fermentation is 8 hours.

6. Filling machine

After the milk fermentation is completed, the filling machine is turned on, and the fresh milk is filled and sealed.

FAQ

1. Do you want to produce liquid yogurt or solid yogurt?

If you are producing liquid yogurt, you need a liquid-related machine.

2. What is your daily capacity ?

We produce 200L, 300L, 500L, 1000L.

3. Do you need to fill yogurt?

We can match the filling machine according to your requirements, can be filled, can be bottled.

4. What is the temperature range of the refrigerating tank?

The temperature range is 4-45 degrees. If it exceeds 45 degrees, the machine will not work.

5. What is the ratio of materials that can be added during the yogurt making process?

The ratio of bacteria to milk and white sugar is: 1L milk plus 6-8% sugar, 1g strain

6. What machines are needed to make yogurt?

Milking - preheating - sterilization barrel - homogenizer - yogurt machine - filling machine

7. What is the working principle of the sterilization barrel?

It is mainly pasteurized by high temperature sterilization.

Customer's voice

Packaging & Shipping

Contact us

Hot Searches