NaN / 0

Open Cell/Close Cell Two Component Polyurethane Rigid Foam Fireproof Spray Polymetric MDI For Insulation Or Injection

Get Latest Price

US$ 2.79

≥450 Kilograms

US$ 0.99

≥720000 Kilograms

Quick Details

CAS No.:

9003-11-6

Other Names:

Polyurethane Rigid Foam

MF:

C3H8N2O

EINECS No.:

210-898-8

Product Details

add my Whatsapp for discount and quick response

add my Whatsapp for discount and quick response

add my Whatsapp for discount and quick response

add my Whatsapp for discount and quick response

add my Whatsapp for discount and quick response

Related Products

Product Description

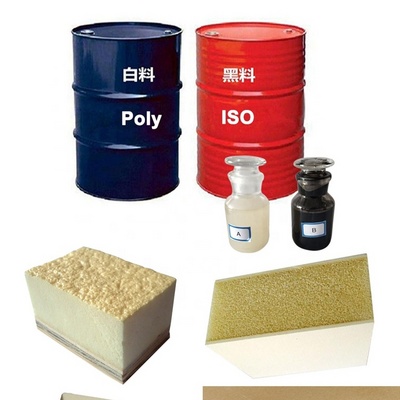

Polyureathane rigid foam BLEND POLYOLS and ISOCYANATE

T-501A is spray blend polyols, it reacts with isocyanate to produce foam which has excellent performances, which are as follows,

1) fine and uniformity cells

2) low thermal conductivity

3) perfect flame resistance

4) good low temperature dimentional stability.

It applies to all kinds of thermal insulation engineering which uses the spray technology, such as cold rooms, pots, large-scale pipelines and construction metope etc.

|

CLOSED CELL POLYURENE MDI &POLY PHYSICAL PROPERTIES

|

|

|

|

|||

|

1

|

Density

|

245FA/ft²

|

33.6kg/³

|

|||

|

2

|

Initial Thermal Resistance (R-value@ 1 inch )See ESR for additional R-Value information

|

7.4ft²hF/BTU

|

1.3Km²/w

|

|||

|

3

|

Air Leakage @75Pa@1”

|

<0.002L/sm²

|

|

|||

|

4

|

Air Permeance @75 Pa@1”

|

<0.002L/sm²

|

|

|||

|

5

|

System Air Leakage Rating ,After wind Conditioning @ ∆

|

<0.0022L/sm²

|

|

|||

|

6

|

Penetrations Check :Continuity at Penetrations @ reference air leakage

|

Pass

|

|

|||

|

7

|

Water vapor Permeance @1.42”

Qualifies as a Class II vapor barrier per IBC Section 202 |

<1perm

|

<57.2ng/Pa•s•m

|

|||

|

8

|

Compressive Strength

|

28.7Psi

|

198kPa

|

|||

|

9

|

Tensile Strength

|

46.2Psi

|

319Kpa

|

|||

|

10

|

Dimensional Stability @158°F(70°C)97% R.H

(168 hrs,sample without any substrate) |

(% volume change )

-1.37/-0.42/+0.27 |

|

|||

|

11

|

VOC Emissions Standard

|

Complaint

|

|

|||

|

12

|

Closed Cell Content

|

≥90%

|

|

|||

Detailed Images

Wood Imitation Rigid Polyurethane Blend Polyols

"Wood Imitation" structure foam, is a new type of carving synthetic materials. It has high mechanical strength and hardness,

simple molding process, high production efficiency and excellent appearance. Characteristics are as follows, 1.Excellent

repetition molding property. It not only can mould certain shape size, but also mould lifelike wood texture and other designs,

good touch. 2.Appearance and feel close to wood, which could be planed, nailed, drilled, and carved patterns or designs. 3.Mold

can be aluminum or steel, and silicon rubber, epoxy resin or other resins, which are low cost and easy machining. 4.Process is

simple, fast, high efficiency of qualified. 5.Physical and mechanical properties is one of optimal synthesis wood produced by

various polymer. Physical property can be controlled by adjusting the formula.

simple molding process, high production efficiency and excellent appearance. Characteristics are as follows, 1.Excellent

repetition molding property. It not only can mould certain shape size, but also mould lifelike wood texture and other designs,

good touch. 2.Appearance and feel close to wood, which could be planed, nailed, drilled, and carved patterns or designs. 3.Mold

can be aluminum or steel, and silicon rubber, epoxy resin or other resins, which are low cost and easy machining. 4.Process is

simple, fast, high efficiency of qualified. 5.Physical and mechanical properties is one of optimal synthesis wood produced by

various polymer. Physical property can be controlled by adjusting the formula.

|

Appearance

|

Light yellow to brown yellow viscous liquid

|

|

OHvalue mgKOH/g

|

250-400

|

|

Dynamic viscosity (25℃) mPa.S

|

1000-1500

|

|

Density (20℃) g/ml

|

1.10±0.02

|

|

Storage temperature ℃

|

10-25

|

|

Storage stability month

|

6

|

|

Raw materials

|

pbw

|

|

DonFoam 601 polyols

|

100 g

|

|

Powder

|

3-5

|

|

Isocyanate

|

60-100

|

|

Rise time

|

50-70s

|

|

Gel time

|

140-160s

|

|

Tack free time

|

200-220s

|

|

Free density

|

300-850kg/m3

|

|

Moulding density

|

400-1000 kg/m3

|

|

Curving strength

|

7-20 MPa

|

|

Compressive strength

|

7-30 MPa

|

|

Tensile strength

|

5-20 MPa

|

|

Surface strength

|

35-70 (Shore D)

|

|

Shrinking ratio

|

≤0.1%

|

Good feedback

Packing & Delivery

Certifications

Our Service

•Direct factory supplier ,Well and High Quality Control

•Our products with world first-class quality and On-Time Delivery

•Competitive price with excellent quality

•A great variety of different models to meet customer requirements

•Exported to Southeast Asia, Africa, Europe and other regions

•A full-service system integrating manufacture, distribution, repair service and domestic & International trade

•Our service is as close as your phone

•Customer satisfaction is our highest pursuit

•Located in China's newest economic zone Qingdao– the most convenient port city to middle and south Asia and middle east countries

•Highly trained team members with overseas working experience

•The very strong and professional R & D Team

•Response quickly with effective information in 12 hours

•Provide timely professional technical support service

•Not only to sell but to solve customers' problems

•Considerate after-sale service

Hot Searches