NaN / 0

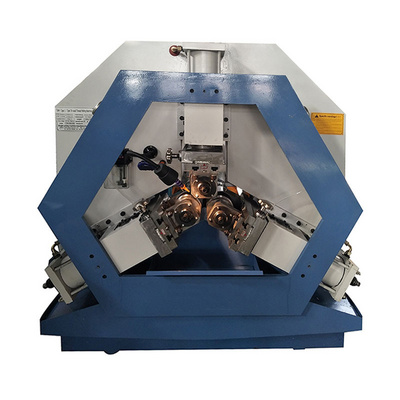

Cold rolling steel bar making machine rebar threading rolling machine

Get Latest Price

US$ 1500

≥1 Sets

US$ 1360

≥5 Sets

US$ 1220

≥10 Sets

Quick Details

Place of Origin:

Henan, China

Product name:

Rebar thread rolling machine

Thread Length:

40-90MM

Rebar Diameter:

12mm-40mm

Product Details

Cold rolling steel bar making machine rebar threading rolling machine

Descriptions:

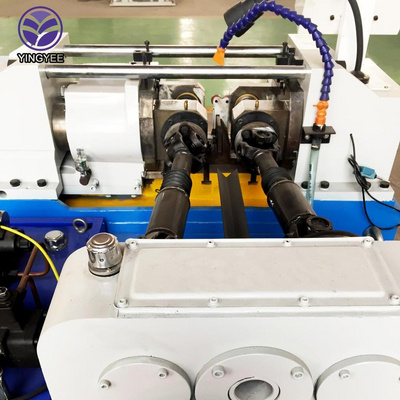

The rebar thread rolling machine main used in steel bar,to make parallel thread end to make a shape, smooth and standard thread. it uses the advanced technology of stripping rib rolling to process the straight thread of the steel connecting end. The straight-threaded metal fiber of the steel bar processed by it is continuously compact and has good comprehensive mechanical properties. The tensile strength is increased by 20%-30%, the fatigue strength is increased by 40%-60%, the corrosion resistance is improved by 50%-200%, and the steel joint strength is higher than that of the steel base material. The mechanical properties of the steel joints meet and exceed the domestic and international standards.

Specifications:

| Name | Rebar thread rolling machine |

| Model | HGS-40F |

| Power | 4KW(380V/50HZ) |

| Rebar Diameter | Φ12-Φ40mm |

| Thread length | 90mm(can be customized) |

| Working distant | 150mm |

| Dimension(L*W*H) | 1250*600*1100mm |

| Weight | 480kg |

Product Description

Features:

1.It can be rolled after stripping ribs, the thread profile is very accurate, and the consistency of the diameter is also very good.

2.Structure compact, operation simple, thread processing speed quick,when processing the stability is high.

3.Its automaticity is very strong, can automatically rise knife, automatically return, and the noise generated by the device is also very small.

4.Easy to adjust for rolling steel bars in different specifications, adjustment can be made without loosing rolling head, with same given screw distances.

Functions

Function:

Used for rebar thread rolling screw, widely used in building, bridge, tunnel construction industry.

Contact

Hot Searches