NaN / 0

Hot sale discount resin polyurethane cnc machine Rampf tooling board plastics suction mould OBO model of sand core box

Get Latest Price

US$ 50

≥1 Sheets

Quick Details

Processing Service:

Moulding

Place of Origin:

Fujian, China

Brand Name:

ZS

Model Number:

ZS460 ZS5100 ZS5120 ZS5166

Product Details

Product Description

DESCRIPTION

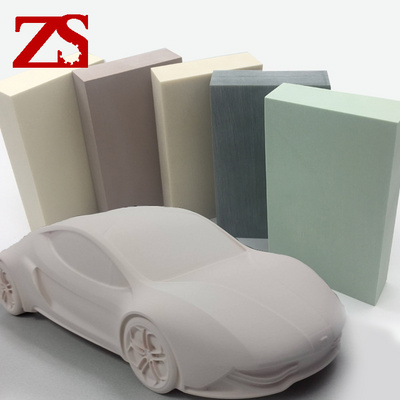

- ZS-Tooling Board has been developed as a polyurethane based material for model and tool making and the manufacturing of checking fixtures and test units. Due to a special specification and a manufacturing method optimized over many years, it is possible to retain the product qualities even in the case of large board dimensions.

- ZS-Tooling Board is especially noteworthy for its smooth and homogeneous surface combined with an even cell structure. It has a high edge stability, small thermal expansion coefficient, low dust formation when being machined, no known physiological effects and odeurs or smell. The range consists of 10 different types, varying in density between 600 - 1500 kg m3. There are 18 different dimensions to a maximum of 2000x1000 mm and thicknesses of up to 200 mm are available. Larger blocks can be achieved when bonding several blocks to eachother.

- Epoxy Tooling board, the toughness, environmental protection, hardness, size stability, temperature tolerance, physical properties such as compressive strength, bending strength is quite good.

- We are quietly supporting these industries, automobiles, high-speed rail, shipbuilding, aviation, ceramics, foundry industry and daily necessities manufacturing and related industrieschecking fixtures, mold, wind power and yacht . Maybe we are also suitable for your product, can try, may have unexpected harvest.

KEY PROPERTIES

- Easy workability • High dimensional stability

- Cost effective • Good compressive strength

- High Temperature and chemical resistance • Large sheet sizes available

- Smooth, non-porous surface finish • Low coefficient of thermal expansion

USES

-

Design studies

-

CNC program milling model / proving / testing.

- Building Landscapes/Features in architectural and scenario models

- Forming a mould tool for prototyping short runs of composite parts.

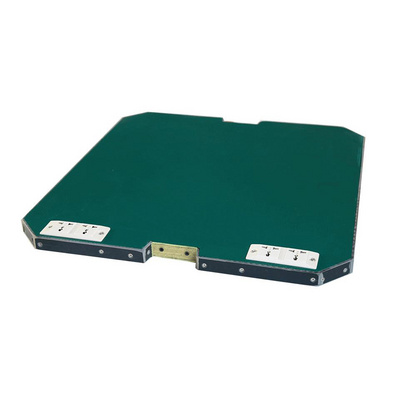

- Use for jigs, fixtures, foundry patterns, core boxes and vacuum forming molds.

Product Data Sheet

| Product name | Cost effective white cream color Density 1.0 g/cm3 ZS5100 ZS-TOOL tooling modeling boards for automotive checking fixture jigs |

OEM Services available:

Providing different materials of tooling boards to our clients,including polyurethane tooling board(polyester materials),epoxy resin tooling boards and urathane tooling boards; The clolors can be manufacture as per client's requirement once the order quantity is reasonable.

Small order acceptable:

We have 10 branches in China, providing the service to many famous car manufacturers and aerospace & airplane companies through our own resources, including automobile checking fixtures, vehicle models and other related service.

Click Here Send Message For Our Product Catalog Or Click Here To View More Products Categories

1 . We have formed services in the aerospace, automotive, yacht and other industries of composite materials and also processing equipment industry chain company,providing composite tooling board materials, tooling board finished products(like model,checking fixtures,die etc.),5 Axis Bridge Maglev CNC machining centers to the clients all over the world.

2.We are the first factory of the first piece tooling board manufacturer in China,with R&D ability for tooling board materials to use in different application. Dimension stability can be guaranteed!

3. We are the long-term partners for each Main automotive manufacturers.

4. We developed a super CNC machine with 80M / MIN fast traverse speed, acceleration up to 1G or more, no backlash drive, machining accuracy + -0.005MM, non-contact transmission, geometric accuracy and long life, can achieve processing roughness RA0. 03μm.

5. Maglev machining center is applied into graphite mold,high precision electrode copper mold machining,specular machining,mobile phone frame arc back cover,electronic products metallic shell processing etc.

6. Maglev Gantry 5 Axis Machining Center,apply into the aerospace industry (aluminum alloy profiles,fuel tanks etc.,Cars & Yacht industry(new energy automobile and aluminum body,battery box,yacht non-metallic modeling,composite,automobile model,yacht model),Mold (Automotive stamping dies,injection mold etc.)

Xiamen Zhisen Electro Equip Co.,Ltd,was found in 1997, which have been committed to research and develop polymer composite, high speed CNC equipment (with linear motor drive), model and checking fixture manufacturing.

At present ,We have several factories located in China,including ONE Composite tooling boards factory, ONE composite mineral material,ONE carbonfiber factory,ONE CNC machinery factory and TEN automatic checking fixtures related factories.

Xiamen Zhisen Electro. Equip Co.,Ltd (Composite Branch) is its branch company for foreign Trade business.

You Can Click Here Send Message For More About Our

Hot Searches