NaN / 0

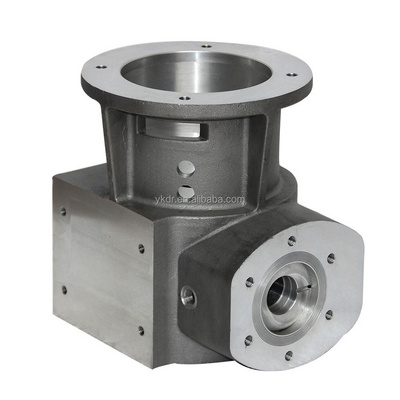

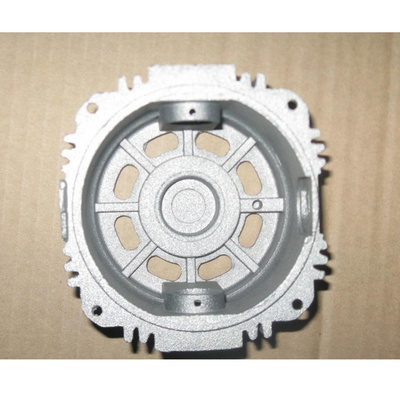

customized die casting product sand casting products aluminum die casting product

Get Latest Price

US$ 6

≥100 Pieces

Quick Details

Place of Origin:

Zhejiang, China

Brand Name:

Gootch

Model Number:

GT-0365

Brand Name::

OEM

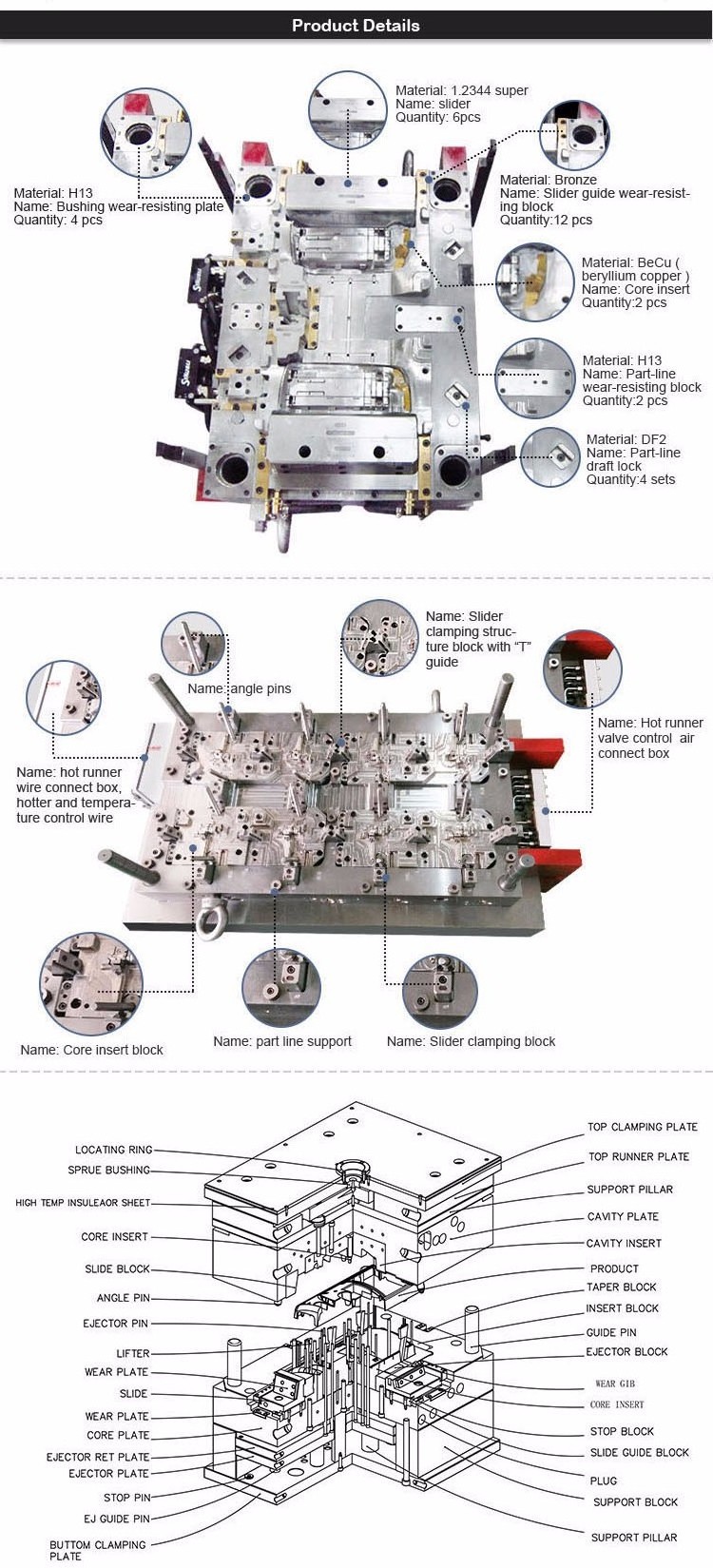

Product Details

Products Description

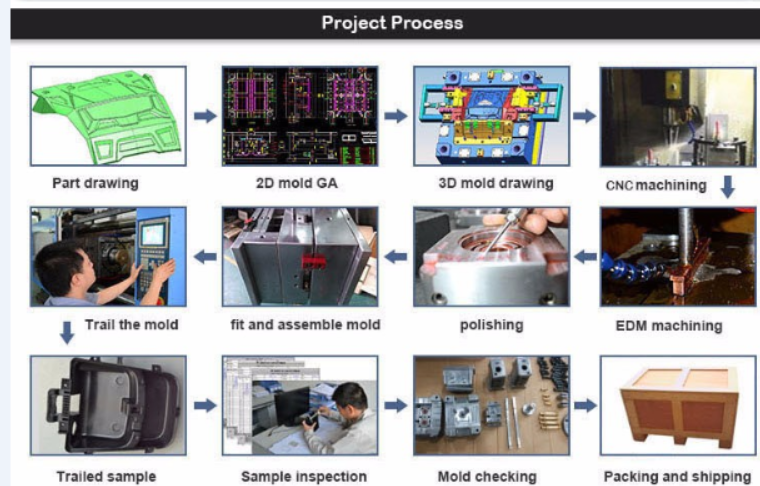

Manufacturing Technique

Product Paramenters

|

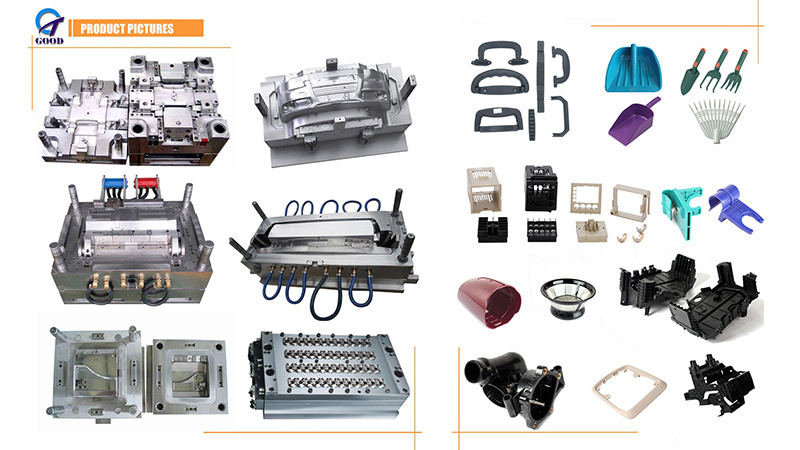

Main services

|

Mold design, Mold making, Mold tesing,Prototypes, low volume/ high volume plastic production

|

|

|

|

|||

|

Design Software

|

UG,Pro E Solidwork,AutoCAD,Moldflow....

|

|

|

|

|||

|

Core&Cavity Material

|

P20,H718,S136,SKD61,2738,DC53,H13....

|

|

|

|

|||

|

Mold base

|

HASCO ,DME ,LKM,JLS standard

|

|

|

|

|||

|

Mould Cavity

|

Singe or multi cavity

|

|

|

|

|||

|

Mold strandard parts

|

DME, HASCO, etc.

|

|

|

|

|||

|

Runner

|

Hot runner, Cold runner

|

|

|

|

|||

|

Hot Runner Brand

|

Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER…etc

|

|

|

|

|||

|

Mold cold runner

|

Side gate,Sub gate,Pin point Gate...

|

|

|

|

|||

|

Mold surface

|

EDM, texture, high gloss polishing

|

|

|

|

|||

|

Hardness of the steel

|

20~60 HRC

|

|

|

|

|||

|

plastic Injection Machine

|

10sets,110T,140T,160T, 200T,260T,320T

|

|

|

|

|||

|

Plastic Material

|

PP,Pa6,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc

|

|

|

|

|||

|

MOQ

|

1set for mold ,plastic products as per your request

|

|

|

|

|||

|

Mold Life

|

300000-500000 shots as per customers' requirement

|

|

|

|

|||

|

Inspection

|

As customers’ requirements

|

|

|

|

|||

|

Delivery

|

Air cargo, Sea shipping

|

|

|

|

|||

|

Lead time

|

25-35days for mold,plastic products according to quantity

|

|

|

|

|||

Exhibition