pu foam machine

adopting three layer storage tank,stainless liner ,sandwich type heating,outer wrapped with insulation , temperature adjustable,safe and energy saving

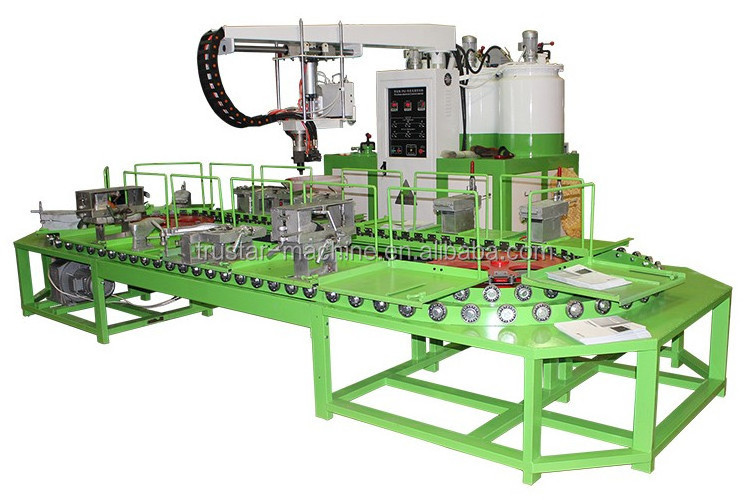

JG -801 Fully automatic PU Shoe Making Machine Price

Two color and three color available

It 's used for making safety shoe, leisure shoe, leather shoe/sole, etc.

1, On the turning circularity molding line which is mould-frame of horizontal multi-position, there are all kinds of specification and model moulds of sole and upper-link molding. When molding line runs equably and circularly, the pouring head of polyurethane foame machine or polyurethane pouring molding two purpose machine pour mix material liquid into the moulds continuously, after the material liquid processed molding in the moulds, which make many kinds of eligible molding shoes or soles.

2, Equipments productivity polyurethane foam machine matches with sole molding molding line(60 position or more), we produce polyurethane soles by 50 shoe moulds, 10 hours one day and 8 circles/hour, as the rotating speed, it can yield 4000 pairs of soles per day.

3, Polyurethane foamed machine matches with sole upper-link molding production line(60 position), we are produce 10 hours one day and 8 circles/hour, as the rotating speed, it can yield 1200 pairs of soles per day.

4, Double color, double density polyurethane sole or upper-link molding shoe products, this techniques should be second pouring, so productivity will be decline

|

shoes making machine price

|

|

|

|

Model

|

JG-801

|

|

|

Tank quantity

|

3

|

|

|

Tank capacity

|

250L

|

|

|

Pump quantity

|

3

|

|

|

Speed of pump(r/min)

|

0---280

|

|

|

Precision (%)

|

±0.5

|

|

|

Max rotating

Speed of injection screw

|

4500/8600-10000(Choice by yourself)

|

|

|

Clean the head

|

Automatic/By hand

|

|

|

Voltage

|

380V,50HZ, or 415v ,60hz

|

|

|

power

|

15(kw)

|

|

|

Clean quantity

|

4500(r/min)>25,9000(r/min)>160

|

|

|

Product characteristics

|

Two color two density

|

|

|

Productivity(output )

|

if work 8 hours can produce 3600pairs of the shoes. every four minute can produce 30prs of the shoe.

|

|

The whole producing line include one main machine, one 60 station convey, one oven

pu foam machine

adopting three layer storage tank,stainless liner ,sandwich type heating,outer wrapped with insulation , temperature adjustable,safe and energy saving

Siemens PLC

Touch screen man-machine interface control panel makes the machine easy to use ,the iperation is absolutely clear.

Servo motor

More accurate measurement; running more stable; no need the frequency converter, no need to set the metering pump speed

Ring production line

There are 60 stations in total, the length is 19 meters including drying tunnel of 16 meters in one side. The heating of drying tunnel can control by electricity or oil, the temperature can be control by automatic, running is stable and speed is variable.

pu sole mold

Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Shoes sample

|

Packaging

|

|

|

|

Size

|

2.6M*1.5M*2.3M

|

|

|

Weight

|

2.6M*1.5M*2.3M

|

|

|

Packaging Details

|

streth film pachage or wooden case,25 days after receiving deposite

|

|

Q:Are you the foreign trade company?

A:No. We have a factory, so if you requires, welcome to visit our factory.

Q:Where is your company? How I can visit it?

A:Our company is located if Ruina City,Zhejiang,China

Welcome to visit our company, it just needs 4hours from Shanghai.

Q:Could we use our own hrand name?

A:Yes,according to your requirements.

Q:What is the material of your products?

A:Steel,cast iron and so on.We can also choose the materials as customers'needs.

Q:What is your delivery time

A:It depends on your order quantity,if just few sets,it needs 20-30days.

Q:What are your payment terms?

A:As usual, 30 deposit and balance T/T before shipment or L/C

Q:Do you also supply shoe mold?

A:Yes,we have shoe mold facotry.Beside providing customers with existing sampless,we also accepts customizing orders.