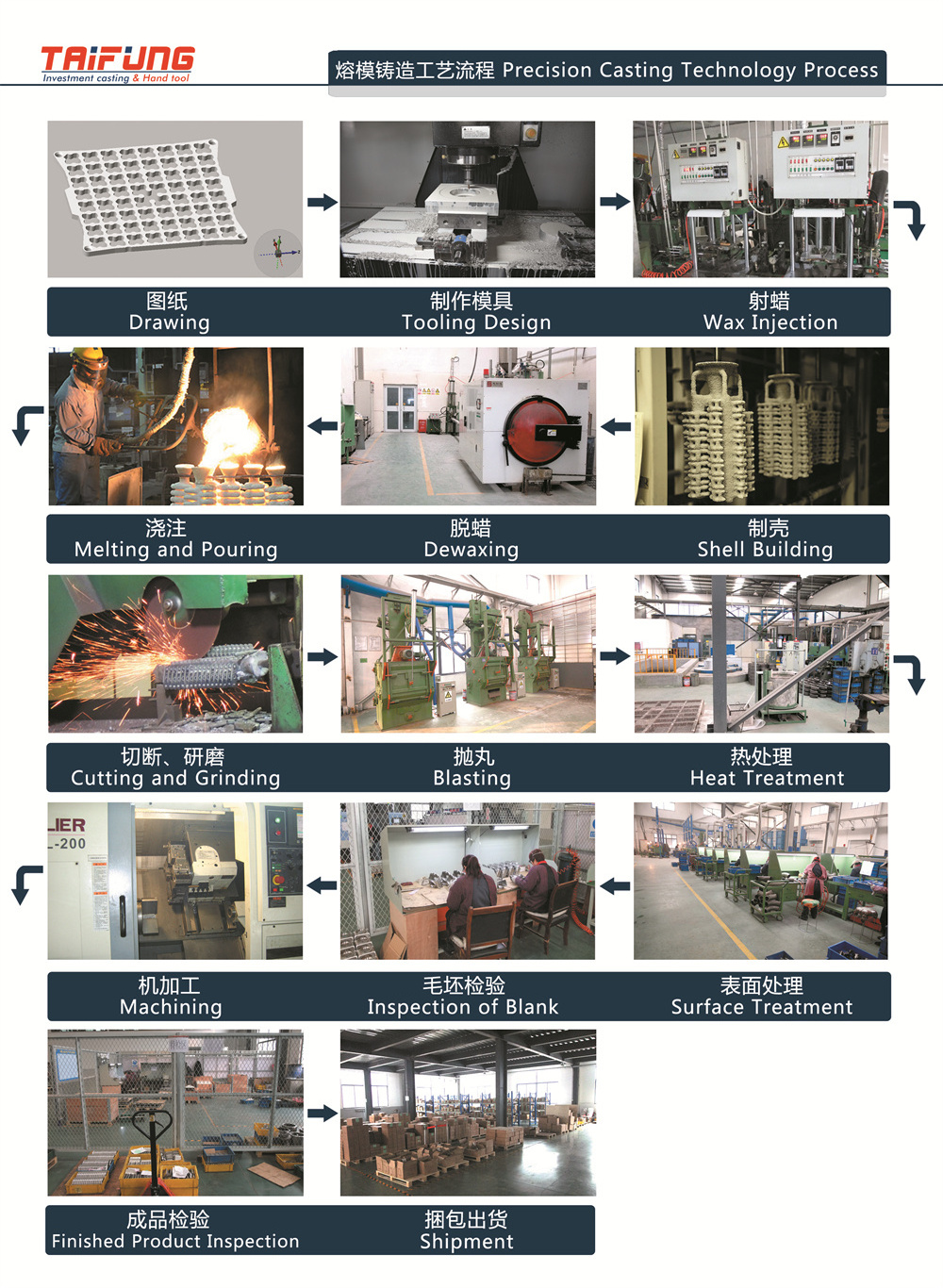

INVESTMENT CASTING PROCESS

In investment casting, a wax or suitable polymer pattern is coated by dipping into the refractory material slurry. Once the

refractory material coating is hardened then this dipping process is repeated several times to increase the coating thickness and

its strength. Once the final coating is hardened the wax is melted out and molten metal is poured into the cavity created by the

wax pattern. Once the metal solidifies within the mould, metal casting is removed by breaking the refractory mould.

Investment casting produces precise components while minimizing material waste, energy, and subsequent machining. It can also

ensure the production of very intricate parts. This makes the investment casting process quite useful to design engineers.