NaN / 0

High Efficiency Gold Recycle Ore Separator Machine Gravity Centrifugal Gold Concentrator

Get Latest Price

US$ 980

≥1 Sets

Quick Details

Production Capacity:

98%

Place of Origin:

HEN

Weight:

100 KG

Application:

Gold

Product Details

High Efficiency Gold Recycle Ore Separator Machine Gravity Centrifugal Gold Concentrator

Products Description

Gold Centrifugal Concentrator

is an efficient equipment for recovering free gold in all particle size ranges, specially for recovery of fine gold which is lost during the operation of the gravitational concentrators (sluice boxes and jigs). It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation, and recover gold from the old tailings.

Application shows that the recovery can be as high as 99%, and the concentrating ratio is up to 1,000 times. In recovering the natural gold in lode ore with size -0. 074mm, the gold is up to 98%, For 0. 004mm in particle size, the gold recovery is 97%. The Gold Concentrator will separate any heavy material from any light material so long as there is sufficient difference in the densities of the individual particles in question. The Concentrator can treat particle sizes from below 10 microns up to a maximum of 6mm and is most commonly used for recovery in Gold and Platinum. Other recovery uses include Mercury, Palladium, Tantalum, Copper, Silver and Diamond Indicator Minerals.

Application shows that the recovery can be as high as 99%, and the concentrating ratio is up to 1,000 times. In recovering the natural gold in lode ore with size -0. 074mm, the gold is up to 98%, For 0. 004mm in particle size, the gold recovery is 97%. The Gold Concentrator will separate any heavy material from any light material so long as there is sufficient difference in the densities of the individual particles in question. The Concentrator can treat particle sizes from below 10 microns up to a maximum of 6mm and is most commonly used for recovery in Gold and Platinum. Other recovery uses include Mercury, Palladium, Tantalum, Copper, Silver and Diamond Indicator Minerals.

Rugged design and a high degree of quality manufacturing ensures that every Concentrator will provide many years of reliable, trouble-free operation in even the most severe operating environments.

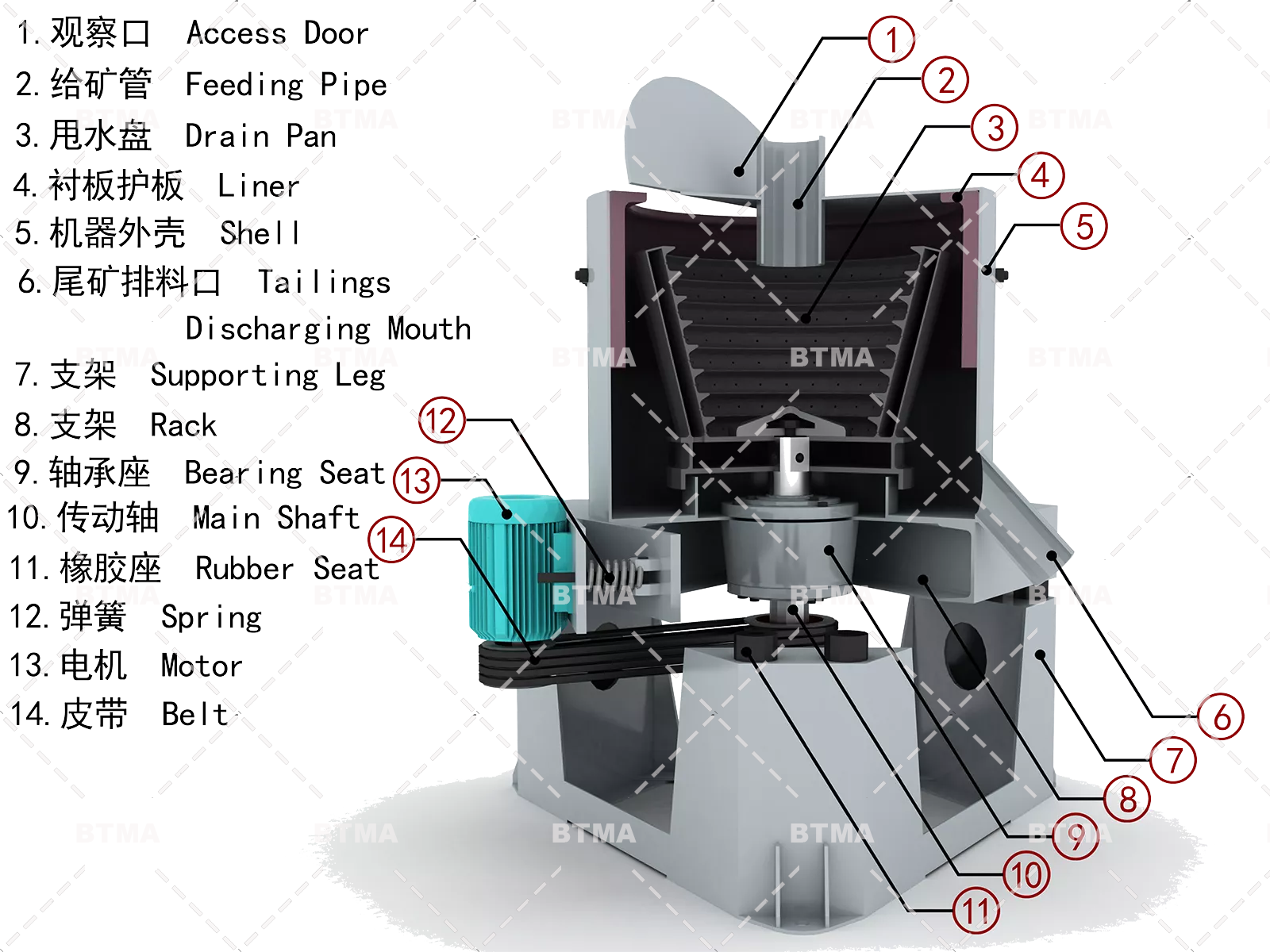

Structure And Working Principle

Working principle

In recovering the natural gold in lode ore with size -0. 074mm, the gold is up to 98%, For 0. 004mm in particle size, the gold recovery is 97%. Lined with rubber riffles along the inner surface. The bowl is mounted on a vertical shaft, which spins at over 100 rpm. Material smaller than 3/8 inch down to 1/8 inch is fed with wash water into the bottom of the bowl. The centrifugal force of the spinning bowl causes a film of material to travel upward along the inside of the bowl. The heavy material catches underneath the riffles and lighter particles are washed out over the rim.

|

Model

|

Feeding Capacity(t/h)

|

Feeding Density(%)

|

Feeding Size(mm)

|

Concentrate Weight(kg)

|

Power(kw)

|

Size(mm)

|

|

STLB20

|

0-0.25

|

0-50

|

0-2.5

|

2-4

|

0.75

|

800x560x710

|

|

STLB30

|

2-3

|

0-50

|

0-4

|

5-10

|

1.5

|

1280x1030x1135

|

|

STLB60

|

8-12

|

0-50

|

0-6

|

15-20

|

4

|

1850x1550x1600

|

|

STLB80

|

10-20

|

0-50

|

0-6

|

35-40

|

7.5

|

2300x1800x2200

|

|

STLB100

|

50-100

|

0-50

|

0-6

|

50-70

|

11

|

2400x2400x2250

|

|

STLB120

|

100-200

|

0-50

|

0-6

|

80-100

|

15

|

2600x2600x2351

|

Details Images

Raw material

Features about our products

5) Easy to operate: After finishing the water pressure and feeding size adjust, clients only need to recover the concentrates every 2-4 hours. (Depending on the grade of the mine)

Paking & Delivery

Hot Searches