NaN / 0

EPS plastic Expandable Polystyrene polypropylene beads granules making machine

Get Latest Price

US$ 65000

≥1 Sets

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

32-64

Screw diameter (mm):

71 mm

Screw Speed (rpm):

600 rpm

Product Details

EPS plastic Expandable Polystyrene polypropylene beads granules making machine

Product Description

Introduction:

Expanded polypropylene (EPP) is an exceptionally eco-friendly, flexible and versatile plastic foam material. It provides excellent energy absorption characteristics, this allows the EPP to recover its shape after impact. Also EPP has very good characteristics of high heat resistance, and resistance to water, oil and most chemicals. In addition, its light weight, can significantly reduce the weight of items.

Technical Data:

|

Mode |

Diameter (mm) |

L/D |

speed (r/min) |

Motor power (kw) |

Torque (N.m) |

Capacity (kg/h) |

|

TSE-20 |

22 | 32-44 | 600 | 5.5 | 43 | 0.5-10 |

|

TSE-30B |

31 | 32-48 | 600 | 15 | 119 | 5-40 |

|

TSH-35B |

35.6 | 32-52 | 600-800 | 15-22 | 119 | 30-70 |

|

TSE-40B |

41 | 32-52 | 600 | 45-55 | 437 | 90-150 |

|

TSH-40B |

41 | 32-52 | 600 | 45-55 | 437 | 150-220 |

|

TSE-5 0 B |

50.5 | 32-52 | 500 | 45-55 | 430 | 180-270 |

|

TSH-52B |

51.5 | 32-60 | 600 | 90-132 | 682 | 270-400 |

|

TSE-65B |

62.4 | 32-64 | 600 | 90 | 716 | 250-360 |

|

TSH-65B |

62.4 | 32-64 | 600-800 | 110-160 | 875 | 350-500 |

|

TSE-75B |

71 | 32-64 | 600 | 132 | 1050 | 350-500 |

|

TS H -75 B |

71 | 32-64 | 600-800 | 200-250 | 1365 | 600-800 |

|

TSE-95B |

93 | 32-64 | 600 | 315 | 2560 | 800-1200 |

|

TSH-95B |

93 | 32-64 | 600-800 | 400-450 | 2506 | 1200-1600 |

|

TSE-135 |

133 | 32-64 | 500 | 550 | 7162 | 1500-2250 |

Application :

EPP is now widely used in automotive components and systems, including seats and other internal components. and multi-use transport packaging (dunnage), HVAC housings and many more.

Description:

The material was formed into small plastic beads by combining the polypropylene resin with pure CO2 in our twin screw extruder machine. the material can be expand 5 times 15 times 30 times, and the particle diameter 1.5~3MM.

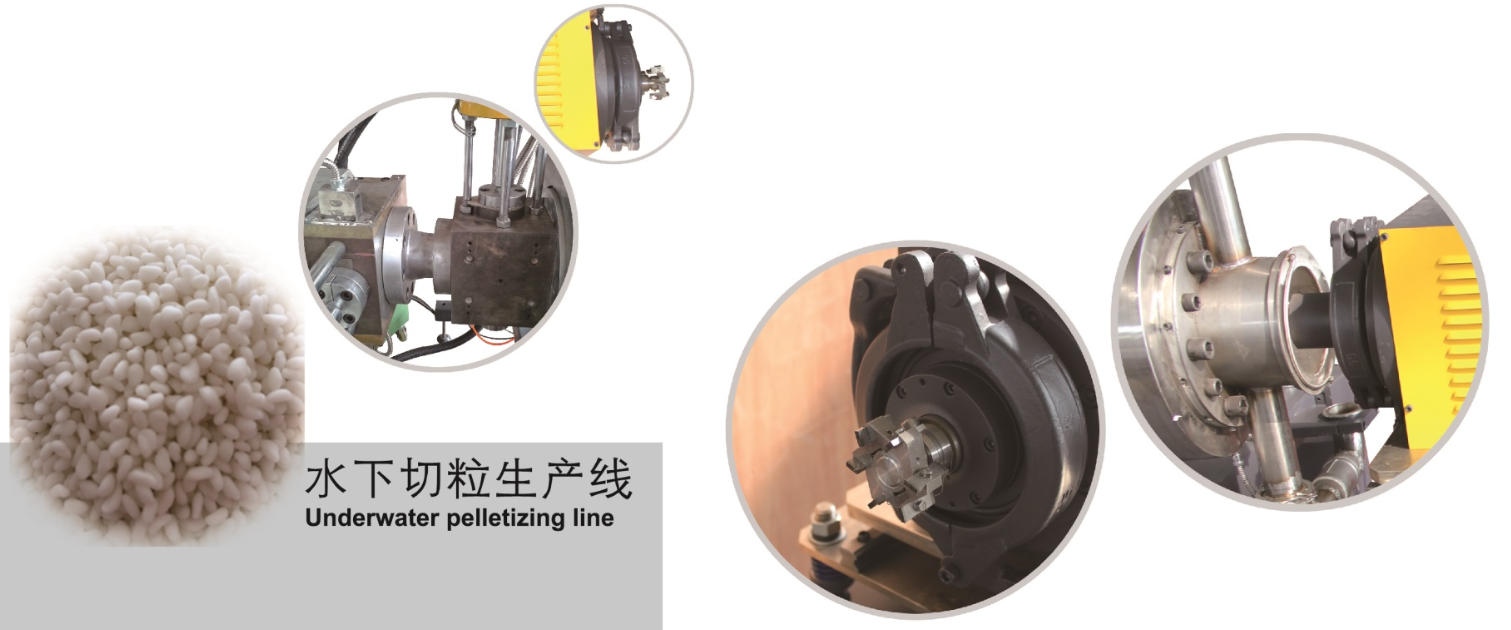

Advanced twin screw extruder characterized by high efficiency mix- ing combined with low energy con- sumption per kg output. The under water pelletizer cuts polymer strands into pellets immediately after they have passed the die plate.

Hot Searches