NaN / 0

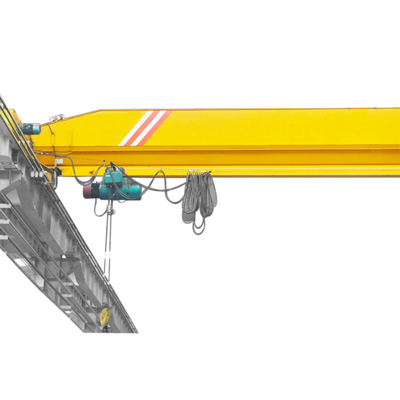

Customized Workshop Bridge Crane 3Ton 5Ton 10Ton 20Ton 32Ton Single Girde Overhead Crane

Get Latest Price

US$ 8300

≥1 Sets

US$ 7800

≥10 Sets

Quick Details

Max. Lifting Height:

6~100m ( Customized )

Rated Lifting Moment:

As per required

Max. Lifting Load:

1~100t ( Customized )

Span:

7.5m~35m ( Customized )

Product Details

Heavy duty 10 ton 20 ton capacity double girder overhead eot crane with electric winch for factory double beam bridge crane

QD Series Double Girder Overhead Crane

| Lifting Capacity | 1~100t (Customized) |

| Span | 7.5m~35m (Customized) |

| Lifting Capacity | 6~100m (Customized) |

| Working Class | A5,A6 |

QD

series double girder overhead cranes offer

special

load capacity for a low deadweight.

Strong

and agile,

its

lifting

capacity

can

up to 100 tons, it is particularly good

tool

for general manufacturing, workshops,

warehouse

and

other

assembly lines. The load hook can be raised between the two crane girders

(beam)

, which

permit

huge

lifting heights

can be make it

.

Overview

SINOCRANE Crane QD series double girder overhead cranes provide special load capacity for a low deadweight. Strong and agile, with lifting capacity (weight) can up to 100 tons, it is particularly good tool for general manufacturing, workshops, warehouse and other assembly lines. The load hook can be raised between the two crane girders (beam) , which permit huge lifting heights can be make it .

This serie

s

of products is matched with

CMG

series wire rope electric hoists

.

1. Design

according to

FEM1.001 and CMAA70 standards.

2. Low deadweight

can

reduce

investment layout

,improve the lifting height.

3. Crane girders can be adapted to building structure

need

s.

4.

C

ompact travelling hoist design

, make crane have

available height and space

.

5. End carriages

with

torsionally rigid,

welded box-section design.

6.

T

o prevent the rail from gnawing

, w

heel group with adjustable structure

.

7. Based on different working conditions, o verload limiter, height limiter, s troke limiter, and other security measures are equipped .

8. Crane control

can

meet

different

application requirements: via radio control,

pendant

control

or cab control (optional).

9. Maintenance platform and accessible crab facilitate maintenance of building interior fittings (optional).

10. Lifting capacity

is

non-standard customized

,

crane

capacity

can be produced

according to clients

’

needs

.

Personalized configuration

Optional maintenance platform and accessible crab.

Control pendant suspended for separate travel on the crane girder with display for installation monitoring.

Optional radio control with display and

push

buttons.

Optional

for

radio control with power and signal transmission.

Optional

for c

ab control.

Features:

l

Optional radio control with display and

push

buttons.

Optional radio control with power and signal transmission.

Optional

c

ab control.

l E ffectively braking , s moot hly moving, long service life.

l Crane spare parts with high safety and reliability.

l C rane is controlled by frequency conversion Three-In-One mechanism with , can reduc e the noise.

Design and Construction Rules

All the standards which are required for the cranes are the FEM standard,

DIN standard and Chinese National standard.

Europe Main National Standards

-- 89/392/EEC standard (93/68/EEC)

-- 91/368/EEC standard

-- 73/23/CEE standard

-- "EMC" standard 89/336/EEC

-- EN 60204-1

-- EN 292 mechanical safety

-- ISO 2141

-- ISO 2766

International Standards

-- June 9, 1993 / Sept. 22, 1993 notice

-- July 29, 1992, 92-765, 92-766, 92-767 notice

-- DIN 5684

-- DIN 15400; DIN 15401

-- NFE 26-010

-- NFE 26-030

Technical Standards

-- FEM 9.511 Mechanical group

-- FEM 9.661 Hoisting and traveling components size and quality standard

-- FEM 9.671 Wire rope quality standard/Chains quality standard.

-- FEM 9.681 Travel motor choice

-- FEM 9.682 Hoisting motor choice

-- FEM 9.755 Electric hoisting equipment

-- FEM 9.811 Electric crane standard

-- FEM 9.901 Hoisting components design reference

-- IEC 34-1 Traveling and allocation performance

-- IEC 34-5 Protection grade standard

-- IEC 947-5-1 Low voltage equipment

China Main National Standards

Design rules for cranes GB/T 3811-2008

Safety rules for lifting appliances GB 6067-2010

Common crane technical condition GB 7592-87

Crane-Overhead traveling crane and portal bridge crane

Notes: If you want to ask any questions about this product directly with us, pls click here !

Send your Inquiry Details in the Below, Click " Send " Now!

If you would like us to provide an accurate quote within 12 hours, please write down the following information:

1. Lifting Capacity is ____t

2. Span is____m

3. Lifting Height ____m

4. Working Conditions_____

5.

Power source is____v,____hz, ____phase.

6

. Your contact information. Both Email and phone number are essential

.