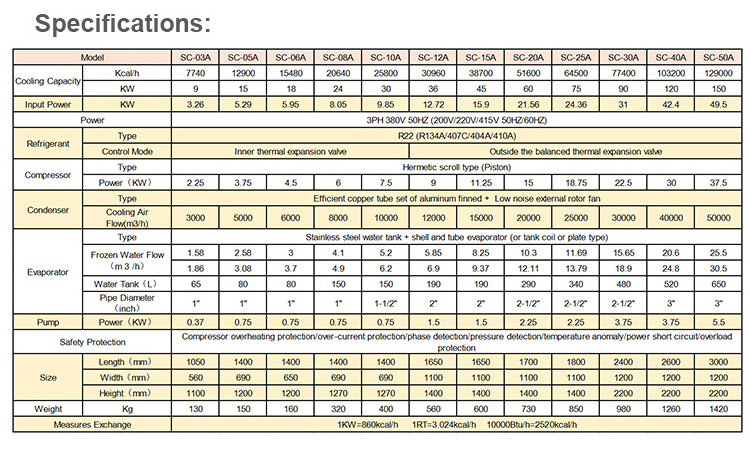

NaN / 0

Industrial water cooling chiller 30ton air cooled cooling machine chiller price

Get Latest Price

US$ 11900

≥1 Sets

Quick Details

Condition:

New

Place of Origin:

Jiangsu, China

Brand Name:

Startemp

Voltage:

380v/3phase/50hz

Product Details

Air Cooled Chiller

Water circulation system: The water pump takes the water out of the water tank and pumps it to the equipment that the user needs to cool. The chilled water takes the heat away and the temperature rises, and then returns to the chilled water tank.

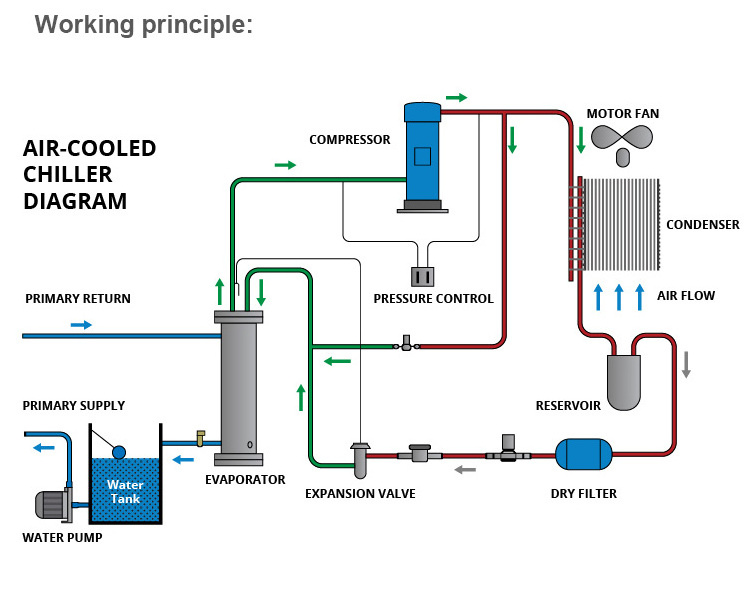

Air cooled water chiller is mainly applied to a cooling process in molding of plastic film and PE plastics bag or other industries. The chiller will greatly improve quality of molded products and shorten period of injection molding cycles. The max different is the way of heat radiation by fans with water cooled chiller. There are three main interrelated systems: refrigerant circulation system, water circulation system, electrical control system.

Refrigerant circulation system: The liquid refrigerant in the evaporator absorbs the heat in the water and begins to evaporate. Finally, a certain temperature difference is formed between the refrigerant and the water. The liquid refrigerant also completely evaporates into the gas phase, and is then inhaled and compressed by the compressor (pressure and temperature increase). After being throttled through the expansion valve (or capillary), low temperature and low pressure refrigerant enters the evaporator to complete the refrigerant circulation process.

Water circulation system: The water pump takes the water out of the water tank and pumps it to the equipment that the user needs to cool. The chilled water takes the heat away and the temperature rises, and then returns to the chilled water tank.

Features:

Basic functions:

* Adopt the brand scroll compressor, such as: Copeland, Sanyo, Panasonic, Daikin.

* Non - oxygen welding the internal copper pipe.

* High efficiency evaporator and V type finned condenser.

* Adopt the 304 SS water tank to prevent corrosion and rust.

* PID controller system can maintain accuracy within ±0.1℃, convenient operation.

* Imported electrical accessories, Omron、Te、LS、ABB、Schneider、Siemens etc.

* The whole unit box type structure, beautiful appearance, compact structure, easy to check the operation of the unit at any time.

* Unit equipped with the 304 SS water circulating pump according to the cooling capacity, no need install the water tower, convenient installation and maintenance.

* Multiple safety devices protection and fault display system improvement, maintenance no need the professional personnel.

Optional functions:

* Cooling and heating in one machine can be customized.

* RS485 communication, which can realize automation management.

* PLC control, high reliability, strong anti-jamming capability.

* Explosion proof design of electric control cabinet and pipeline.

* Various refrigerant R22,R407C,R410,R134A,R404A.

Q: May I know the status of my order?

A: We will send you information and photos at different production stage of your order, You will get the latest information in time.

Q: Do you offer shipment facilities?

A: Yes! We do. The shipment is done by a third party. The shipment cost is free inside China. For overseas you can select shipping agents by yourself or we can support you to find reliable shipment companies.

Q: Are your products can be customized?

A: Yes. Also welcomed to customized non-standard products.

Q: Whats your payment term?

A: TT 100% before shipment, LC at sign, Western Union or Trade Assurance order.

Q: How do you ship the goods and lead time?

A: We usually ship by sea. Sometime shipped by air. About 5-25working days for delivery as per different model.

Q: Do you offer guarantee for the products?

A: Yes, we offer 12 months warranty.